Preparation method of gas-phase high-impact polypropylene instead of low-purity nitrogen

A technology of high-impact polypropylene and gas-phase method, which is applied in the field of preparation of high-impact polypropylene by gas-phase method, which can solve the problems of low catalyst activity and low ethylene content, and achieve strong dispersion, improved impact strength, and continuous stability The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

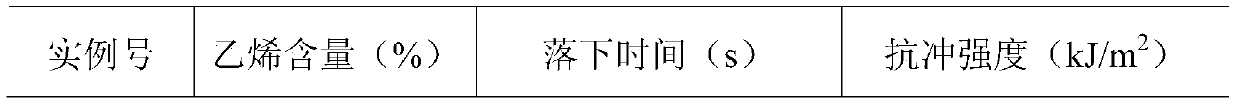

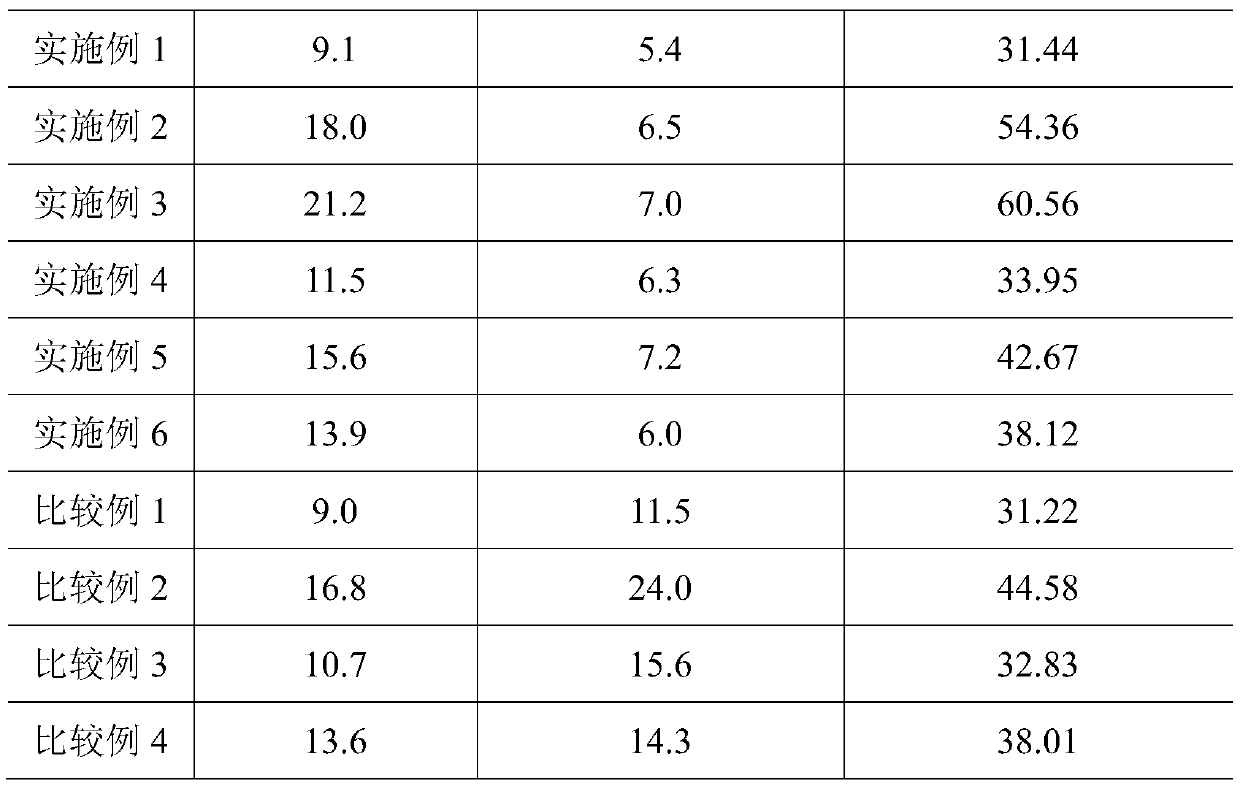

Examples

Embodiment 1

[0045] Embodiment 1, a kind of preparation method of gas-phase process high-impact polypropylene that replaces low-purity nitrogen, the following steps are carried out in sequence:

[0046] (1) Homopolymerization of propylene:

[0047] The supported Ziegler-Natta catalytic system consists of MgCl 2 / TiCl 4 Type catalyst 2.3g and particle diameter are 50nm superfine titanium dioxide 30mg composition; The MgCl 2 / TiCl 4 The catalyst is based on (9,9-bis(methylmethoxy)fluorene as the internal electron donor, MgCl 2 As a carrier, loading TiCl 4 the catalyst;

[0048] MgCl 2 / TiCl 4 The specific preparation method of the type catalyst is: 4.8g (0.05mol) of anhydrous MgCl 2 After adding 0.025mol 9,9-bis(methylmethoxy)fluorene under the protection of nitrogen, it was immersed in a solution containing 0.48g (2.5mmol) TiCl 4 hexane solution (about 10ml), followed by filtration drying (drying at 60°C for 120 minutes) to give MgCl 2 / TiCl 4 type catalyst.

[0049] The prepara...

Embodiment 2

[0055] Embodiment 2, a method for preparing high-impact polypropylene by gas phase method instead of low-purity nitrogen, the following steps are carried out in sequence:

[0056] (1) Homopolymerization of propylene:

[0057] The supported Ziegler-Natta catalytic system consists of MgCl 2 / TiCl 4 Type catalyst 1.8g and particle diameter are 20nm superfine calcium carbonate 18mg composition; The MgCl 2 / TiCl 4 The type catalyst uses 9,9-bis(benzylcarboxymethyl)fluorene as the internal electron donor, MgCl 2 / TiCl 4 as a carrier catalyst;

[0058] MgCl 2 / TiCl 4 The specific preparation method of the type catalyst is: 9.5g (0.1mol) anhydrous MgCl 2 After adding 0.15mol 9,9-bis(benzylcarboxymethyl)fluorene under the protection of nitrogen, it was immersed in a solution containing 1.9g (9.9mmol) TiCl 4 hexane solution (about 20ml), followed by filtration and drying to obtain MgCl 2 / TiCl 4 type catalyst.

[0059] The preparation method of the supported Ziegler-Natta ca...

Embodiment 3

[0065] Embodiment 3, a method for preparing high-impact polypropylene by gas-phase process instead of low-purity nitrogen, the following steps are carried out in sequence:

[0066] (1) Homopolymerization of propylene:

[0067] The supported Ziegler-Natta catalytic system consists of MgCl 2 / TiCl 4 Type catalyst 3.1g and particle diameter are the superfine silica 0.31g composition of 10nm; The MgCl 2 / TiCl 4 The catalyst is di-n-butyl phthalate as internal electron donor, MgCl 2 / TiCl 4 as a carrier catalyst;

[0068] MgCl 2 / TiCl 4 The specific preparation method of the type catalyst is: 9.5g (0.1mol) anhydrous MgCl 2 Add 0.13 mol of di-n-butyl phthalate under the protection of nitrogen without water, and then impregnate in a solution containing 0.5 g (2.6 mmol) of TiCl 4 hexane solution (about 10ml), followed by filtration and drying to obtain MgCl 2 / TiCl 4type catalyst.

[0069] The preparation method of the supported Ziegler-Natta catalytic system is: adding th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com