Safe moving and withdrawing method of complex-structured thick coal seam fully mechanized heavy equipment

A technology of extra-thick coal seam and heavy equipment, applied in mining equipment, earth-moving drilling, installation of bolts, etc., can solve the problems of high removal cost, long time, and outstanding safety problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

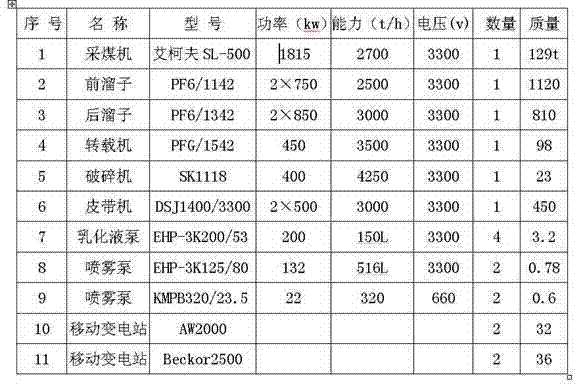

[0020] A method for safely moving and withdrawing heavy equipment for fully mechanized caving in extra-thick coal seams with a complex structure described in the present invention includes support for stopping mining, roof support during removal, and a removal route.

[0021] At present, the roadway layout and ventilation system of the fully mechanized coal caving face with complex structure and extra-thick coal seam are as follows:

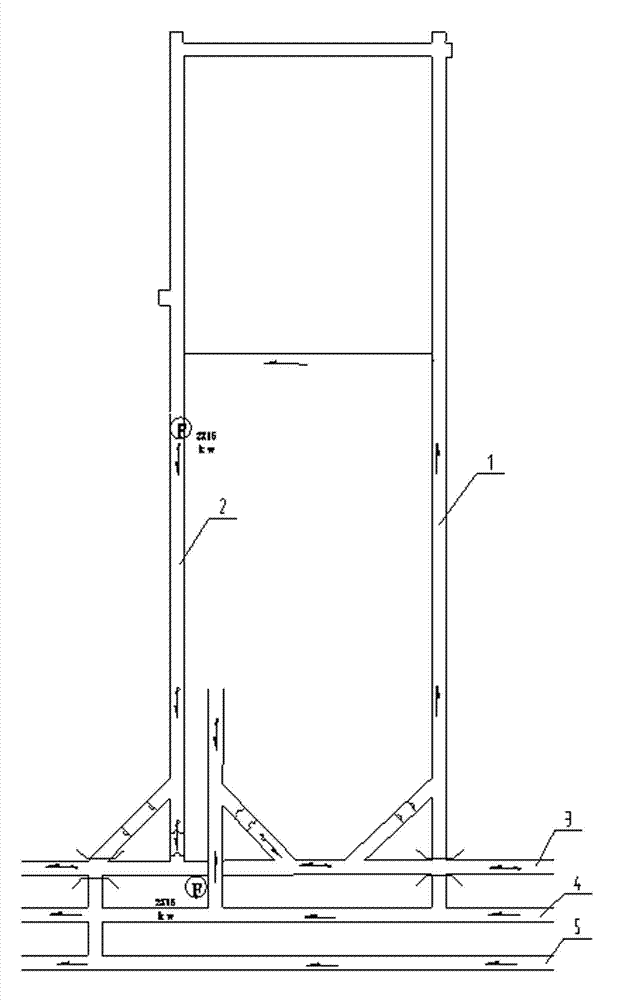

[0022] Roadway layout of working face

[0023] The working face is arranged with two lanes, one entry and one return, and the two troughs are perpendicular to the main alley (including belt lane 4, auxiliary transportation lane 5 and return air lane 3), of which belt lane 1 and auxiliary transportation lane 2 are along the coal seam Bottom layout: belt channel 1 is connected to belt lane 4 of the main road, auxiliary transportation channel 2 is connected to the auxiliary transportation lane 5 of the main road through the connecting lane, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com