Lifting type axis glue dripping valve

A lifting type, axis technology, applied in sliding valve, shaft seal, valve details, etc., can solve the problems of slow dispensing speed, unstable quality, rapid wear of needle valve and valve sleeve, etc., to increase the amount of glue, The effect of prolonging the service life

Inactive Publication Date: 2011-06-15

谢泽

View PDF11 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, there are two ways of dispensing glue, one is manual dispensing, which is slow in dispensing speed and unstable in quality; the other is mechanical dispensing, the needle valve and the valve sleeve are sealed through the cone surface, and the needle valve is lowered This way of dispensing glue improves the quality and speed, but when the glue contains solid powder and the pressure is high, the needle valve and valve sleeve will wear quickly, and even prone to abnormal wear, and there will be problems after the needle valve is closed. There is residual glue on the dispensing nozzle, which affects the quality and efficiency of dispensing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

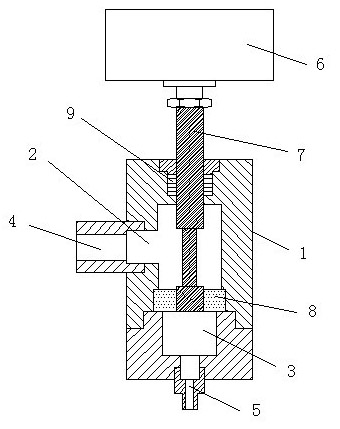

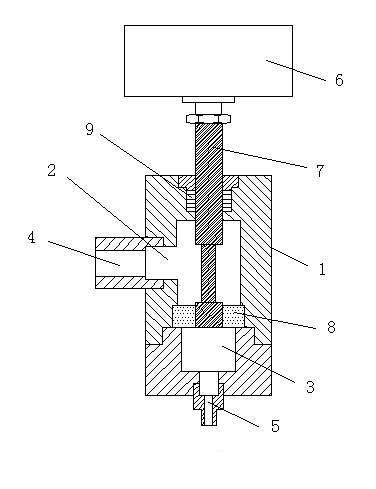

The invention relates to a lifting type axis glue dripping valve, in particular to a glue applying device. The invention aims to provide a glue dripping valve which can stop glue application by lifting a needle valve and can bear larger pressure, and a delivery process is more accurate and is easy to operate. The invention has the following technical scheme: the interior of a hollow valve body is divided into an upper charging cavity and a lower discharging cavity which are respectively communicated with the exterior through a charging port and a discharging port; the columnar needle valve is connected to the lower end of a cylinder and can integrally move up and down under the control of the cylinder; the needle valve passes through the top of the valve body, and the diameter of the middle part of the needle valve is less than the diameter of the lower part of the needle valve; a valve sleeve is fixed on the inner wall of the valve body; when the lower part of the needle valve is matched with the hollow part of the valve sleeve, the charging cavity and the discharging cavity can be separated; and when the needle valve moves down to enable the lower part of the needle valve to be completely positioned in the discharging cavity and the middle part of the needle valve to be positioned at the part of the valve sleeve, the charging cavity is communicated with the discharging cavity. The lifting type axis glue dripping valve provided by the invention is especially suitable for the glue application of a high-consistency and high-viscosity adhesive containing solid fillers.

Description

A lifting type axis dispensing valve technical field The invention relates to a glue dispensing device, in particular to a lifting type axial glue dispensing valve which can quantitatively position glue and close the glue applying system by lifting. technical background At present, there are two ways of dispensing glue, one is manual dispensing, which is slow in dispensing speed and unstable in quality; the other is mechanical dispensing, the needle valve and the valve sleeve are sealed through the cone surface, and the needle valve is lowered This way of dispensing glue improves the quality and speed, but when the glue contains solid powder and the pressure is high, the needle valve and valve sleeve will wear quickly, and even prone to abnormal wear, and there will be problems after the needle valve is closed. There is residual glue on the dispensing nozzle, which affects the quality and efficiency of dispensing glue. Contents of the invention The object of the presen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16K3/24F16K31/12F16K41/02

Inventor 谢泽

Owner 谢泽

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com