Electromagnetic relay with good anti-falling performance

An electromagnetic relay and performance technology, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of abnormal function, unrecoverable deformation of the moving reed 511', and achieve low cost, increased production process, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

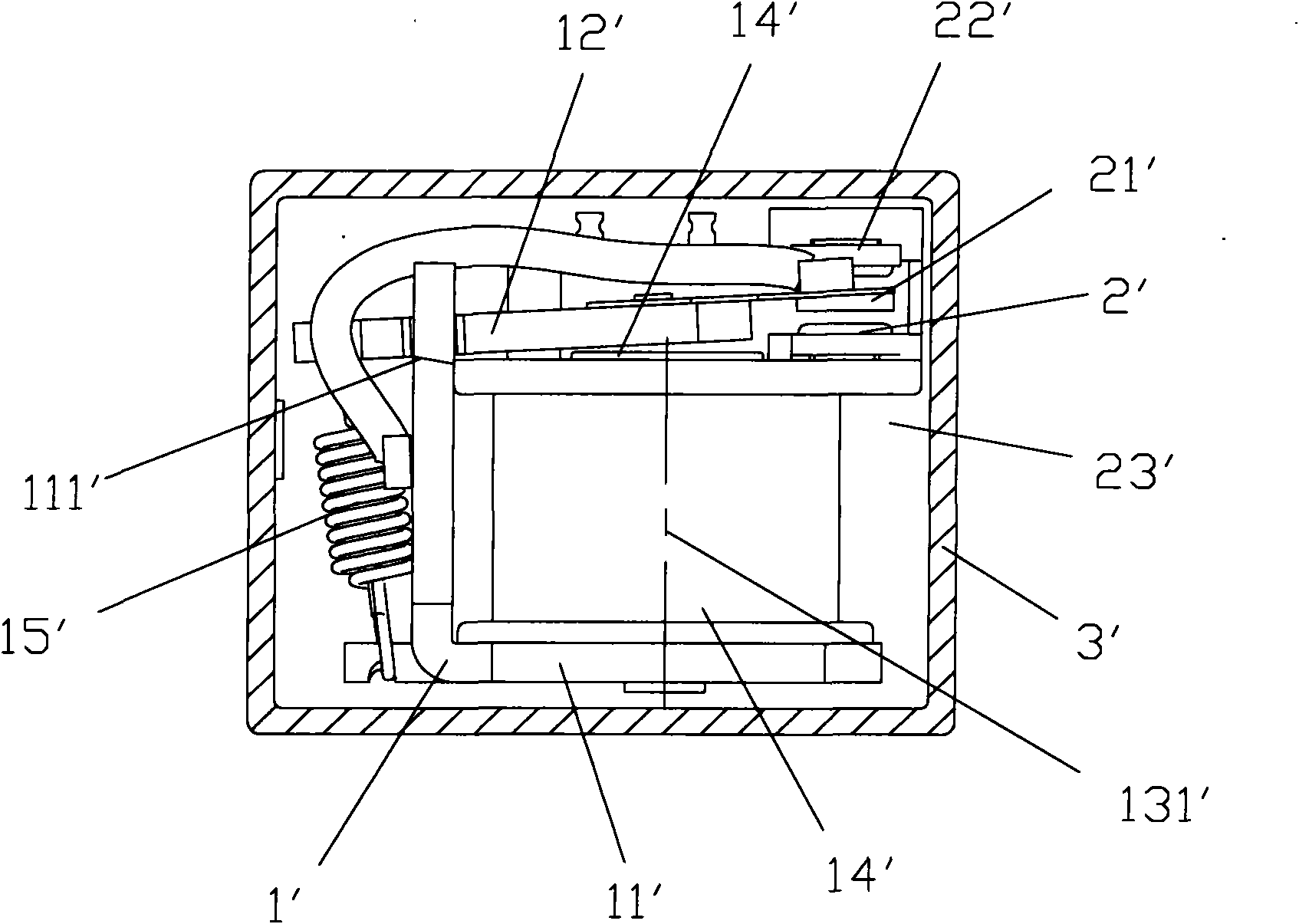

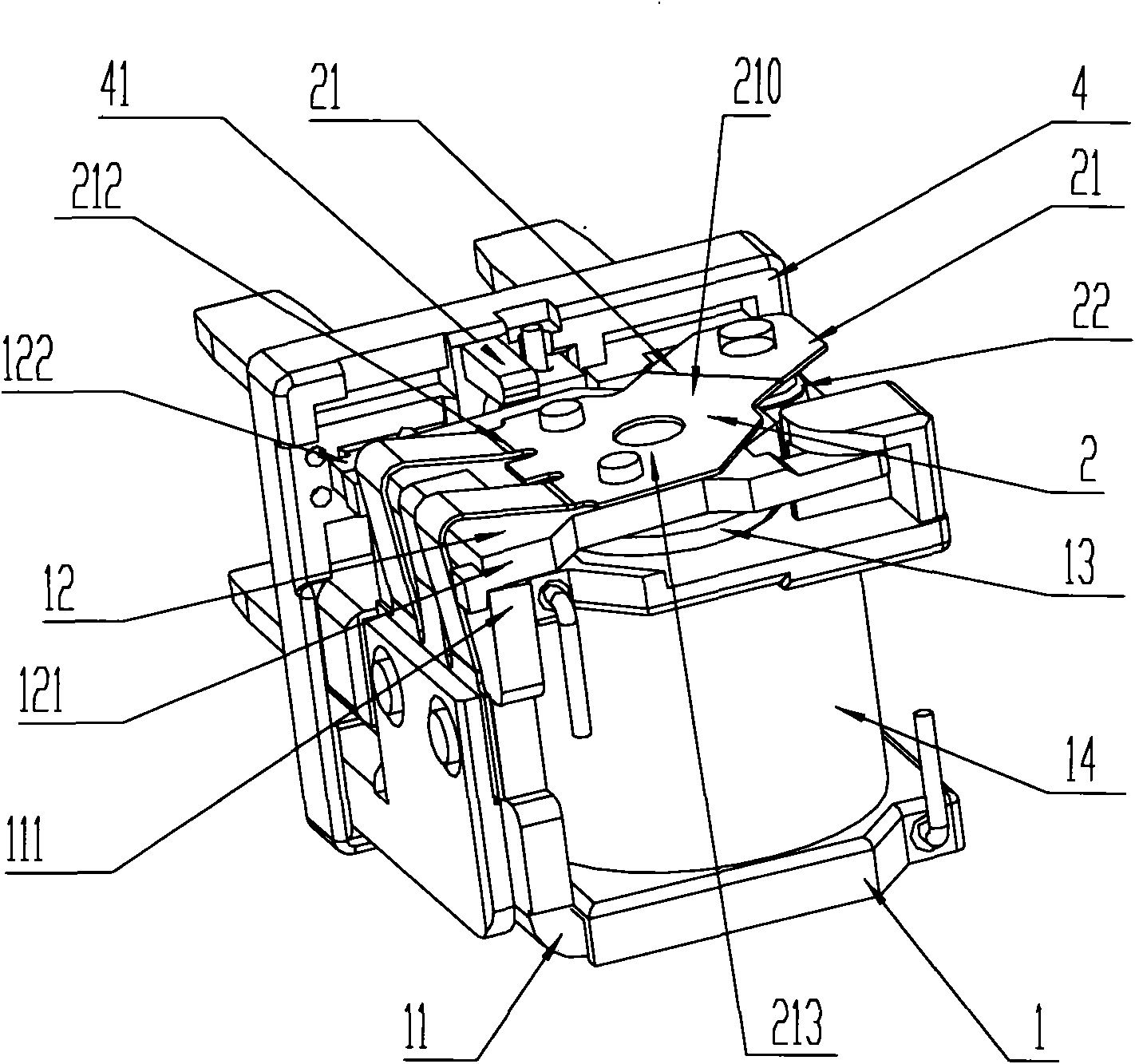

[0029] Embodiment one, see Figure 3 to Figure 8 As shown, an electromagnetic relay with good anti-drop performance of the present invention includes a magnetic circuit part 1, a contact part 2, a housing 3 and a base 4; the housing 3 and the base 4 are connected, and the magnetic circuit part 1 and the contact part 2 The magnetic circuit part 1 is horizontally installed on the base 4; the magnetic circuit part 1 includes a coil 14, a yoke 11, an armature 12 and an iron core 13; the iron core The axis 131 of 13 is parallel to the plate surface of the base 4; the contact part 2 includes a moving spring 21 with a moving contact and a static spring 22 with a static contact; 11 and the armature 12, and the moving spring 21 is riveted together with the armature 12 and the yoke 11, the contact reaction force is generated by the moving spring 21, and the moving spring 21 is provided with a The first bending line 211 and the second bending line 212 attached to the armature, the movin...

Embodiment 2

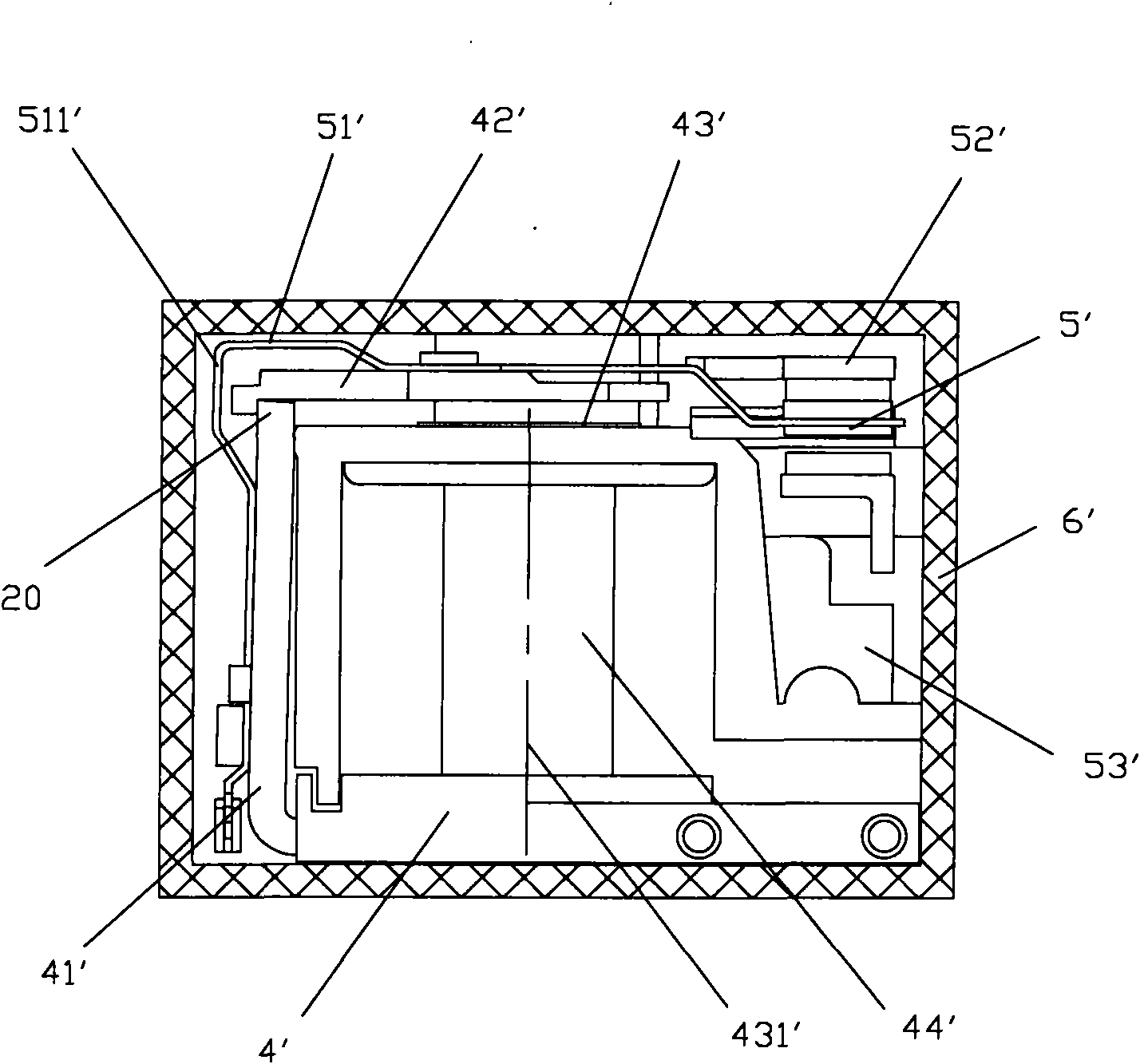

[0032] Embodiment two, see Figure 9 to Figure 14 As shown, an electromagnetic relay with good anti-drop performance of the present invention includes a magnetic circuit part 5, a contact part 6, a housing 7 and a base 8; the housing 7 is connected to the base 8, and the magnetic circuit part 5 and the contact part 6 Respectively housed in the cavity surrounded by the shell 7 and the base 8; the magnetic circuit part 5 is horizontally installed on the base 8; the magnetic circuit part 5 includes a coil 54, a yoke 51, an armature 52 and an iron core 53; the iron core The axis 531 of 53 is parallel to the plate surface of the base 8; the contact part 6 includes a moving spring 61 with a moving contact and a static spring 62 with a static contact; 51 and the armature 52, and the moving spring 61 is riveted together with the armature 52 and the yoke 51, the contact reaction force is generated by the moving spring 61, and the moving spring 61 is provided with The first bending lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com