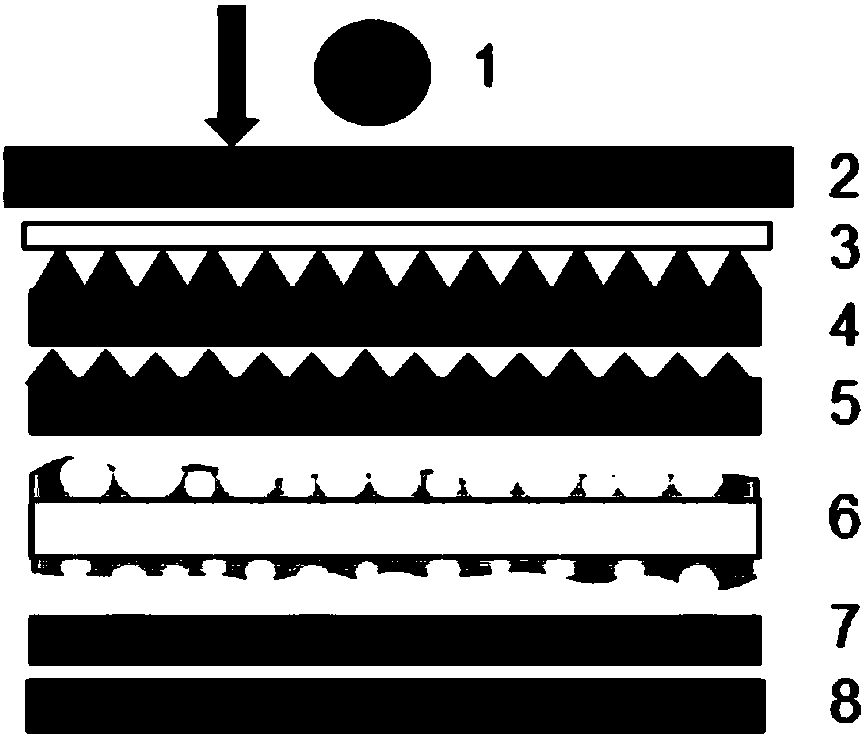

Diffusion film, preparation method of diffusion film, and application of diffusion film

A diffusion film and silicone technology, applied in optics, instruments, optical components, etc., can solve the problems of hard nylon particles, poor anti-dropping and anti-scratch performance of the lower diffusion film, and fragile polyurethane particles, so as to reduce water absorption. performance, improved scratch resistance, compounding and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the diffusion membrane provided by the invention comprises the following steps:

[0035] (1) Weigh ethyl acetate, acrylic resin glue, and then weigh the modified silicone elastomer, and stir mechanically for 30 minutes after mixing;

[0036] (2) Take the auxiliary agent and isocyanate again, and mechanically stir for 30 minutes;

[0037] (3) Coating the above-mentioned mixed coating solution on one side of the substrate, and the prepared diffusion membrane was left to mature for 48 hours.

[0038] Further, the other side of the substrate in step (3) has been coated with a diffusion layer.

[0039] Further, the coating parameters in step (3) are: anilox roll number EXT-160, line speed 15m / min, tension 6N, corona opening, edge scraping, positive winding direction.

[0040] Diffusion membrane provided by the invention is tested according to the following methods:

[0041] 1. Anti-falling ball: The cured finished product is subjected to a fallin...

Embodiment 1

[0047] The present invention provides a diffusion film, the diffusion film includes an anti-adhesion layer, and the anti-adhesion layer includes modified silicone elastomer particles.

[0048] The preparation method of the diffusion film is as follows (the weight ratio of the modified silicone elastomer to the adhesive resin is 1:50):

[0049] (1) Weigh 4.5kg of acrylate glue, 8kg of ethyl acetate solvent, 0.1kg of modified silicone elastomer particles, and mechanically stir for 30 minutes;

[0050] (2) Weigh 0.56kg of auxiliary agent and isocyanate, add it, and stir for 30min;

[0051] (3) Apply the liquid material on-line to obtain the finished diffusion membrane; then place it for 48 hours to mature.

[0052] The cured finished product was subjected to a ball drop test, and there was no ball mark after the ball drop test, indicating that the anti-adhesion layer has good anti-drop ball performance.

[0053] The cured finished product is subjected to a friction test, and af...

Embodiment 2

[0056] The diffusion film as provided in Example 1, except that the weight ratio of the modified silicone elastomer to the adhesive resin is 1:75.

[0057] The cured finished product was subjected to a ball drop test. After the backlight module was turned on, the depth of the ball marks was observed. There were slight marks, and the result was worse than that of Example 1.

[0058] The cured finished product is subjected to a friction test, and after the friction test, the damage of the light guide plate is observed. Judging from the depth and number of scratches on the light guide plate, the light guide plate has obvious scratches, and the result is worse than that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com