High-performance motorcycle battery and manufacturing method thereof

A motorcycle and high-performance technology, applied in the direction of lead-acid batteries, battery components, final product manufacturing, etc., can solve the problems of large self-discharge and large water loss, so as to improve the service life, reduce the self-discharge rate, and avoid The effect of leakage

Inactive Publication Date: 2011-06-15

JIANGSU LEOCH BATTERY

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This kind of traditional motorcycle battery consumes a lot of water during use, and needs regu

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

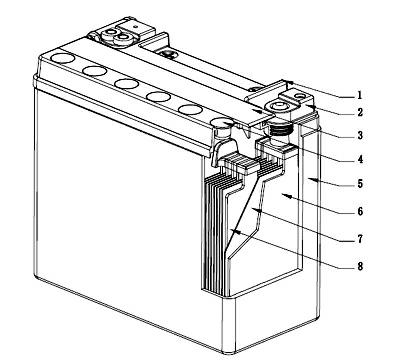

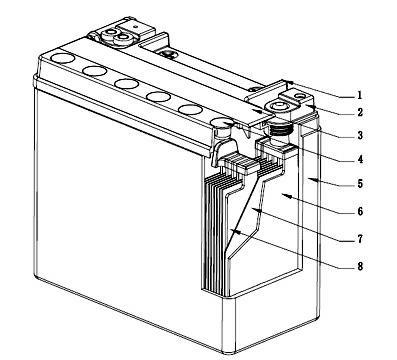

The invention discloses a high-performance motorcycle battery and a manufacturing method thereof. Separate electrode groups are arranged in a mold cavity consisting of a battery shell (5) and a battery cover (1), and are connected with one another in a through the partition welding way. Each separate electrode group consists of a positive plate (8), a negative plate (6) and a partition board (7). The separate electrode groups are connected in a cast welding way by machines. The partition boards (7) are covered on the positive plates (8) and the negative plates (6). Lead terminals (2), a surface patch (3) and filling plugs (4) are arranged on the battery cover (1). The surface patch (3) and the filling plugs (4) are covered on the battery cover (1) in an ultrasonic welding way. The lead terminals (2) are welded on the battery cover (1) by an automatic terminal welder. The battery produced by the manufacturing method solves the main problems of the conventional motorcycle battery, and radically improves the performance of the battery.

Description

A kind of high-performance motorcycle battery and manufacturing method thereof technical field The invention relates to a battery and a manufacturing method thereof, in particular to a high-performance motorcycle battery and a manufacturing method thereof. Background technique Lead-acid batteries are widely used in energy, transportation, electric power, starting and other fields due to their advantages such as stable quality, low price, long cycle life, and easy use. At present, the motorcycle batteries produced by most manufacturers still use the traditional manufacturing process: lead-antimony alloy casting grids, ordinary composite glass fiber separators, traditional lead terminal structure design, and smooth shell surface. This kind of traditional motorcycle battery consumes a lot of water during use, and needs regular water maintenance, and has a large self-discharge, so it needs to be recharged regularly. Contents of the invention The purpose of the present inve...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): H01M4/68H01M10/14H01M10/12H01M2/30B62M6/90

CPCY02E60/126Y02E60/10Y02P70/50

Inventor 彭小勐袁芳梁天保尹波

Owner JIANGSU LEOCH BATTERY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap