Anode active substance and its preparing method and anode and battery

A positive electrode active material and oxide technology, which is applied in the field of positive electrode active material and its preparation of alkaline secondary batteries, can solve the problem of affecting battery cycle performance, charge and discharge efficiency performance, inability to overcome battery self-discharge rate, and affecting cobalt coating Layer utilization and other issues to achieve the effect of overcoming the micro-short circuit of the battery, preventing the loss of cobalt on the positive active material, and avoiding the loss of cobalt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

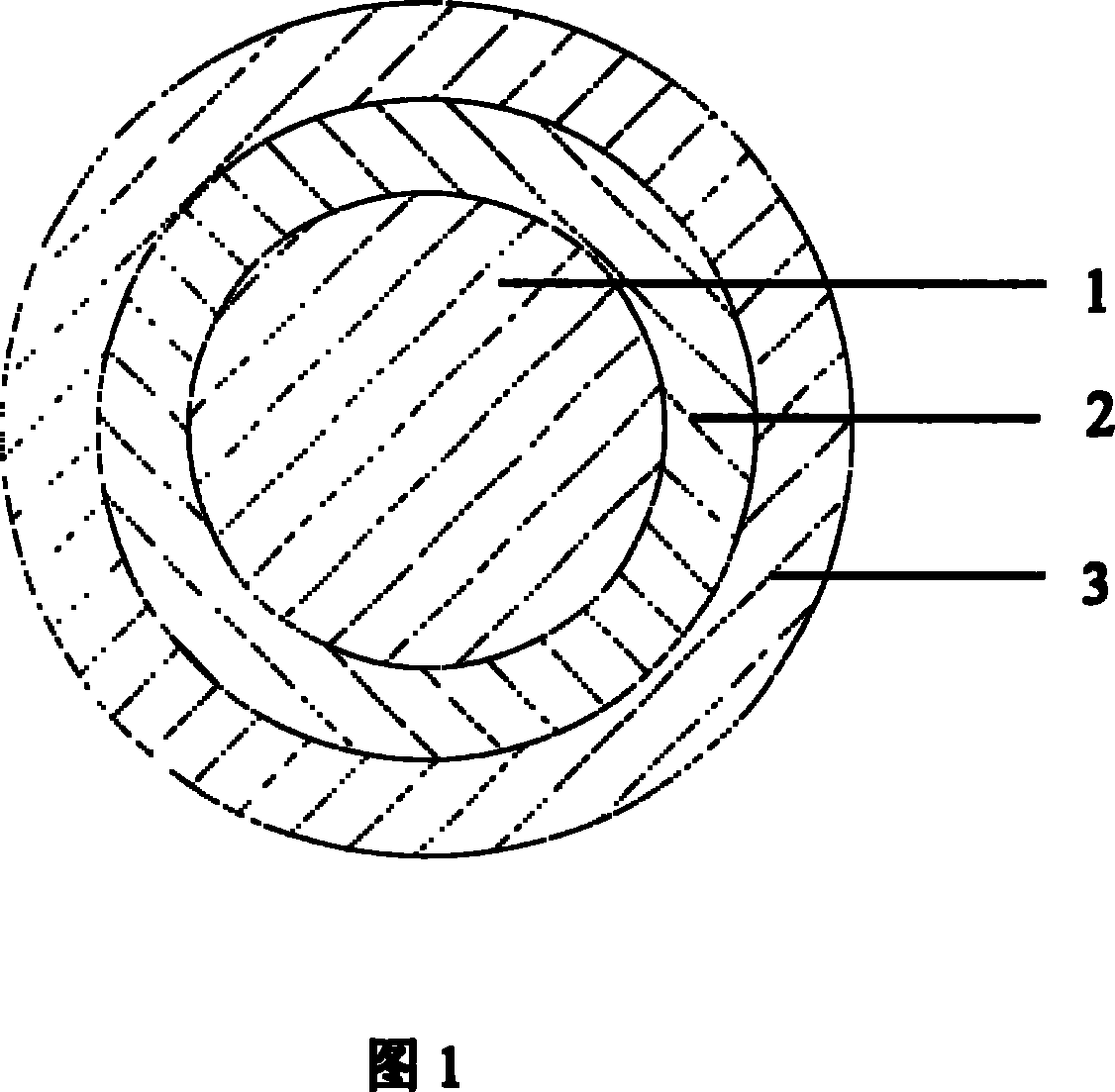

[0028] The present invention also provides a method for preparing the above-mentioned positive electrode active material, wherein the method comprises wetting the nickel hydroxide particles 1 coated with cobalt oxide and / or hydroxide coating layer 2 with an aqueous solution of metal salt, Drying, contacting the obtained nickel hydroxide particles 1 coated with cobalt oxide and / or hydroxide coating 2 with a metal salt on the surface, and washing with an alkaline solution, wherein the aqueous solution of the metal salt is selected from One or more of the aqueous solutions of soluble salts of magnesium, barium, zinc, calcium, titanium, aluminum, tantalum, manganese, yttrium, chromium, cadmium, strontium and lanthanide rare earth elements. The soluble metal salt is one or more of metal sulfate, metal halide and metal nitrate. Considering the problem of environmental pollution, preferably the aqueous solution of the metal salt is selected from one or more of the aqueous solutions o...

Embodiment 1

[0062] This example illustrates the positive electrode active material provided by the present invention and its preparation method.

[0063] (1) Coating cobalt hydroxide layer for nickel hydroxide particles

[0064] Put 100 grams of commercially available nickel hydroxide particles (Japan, Tanaka spherical nickel hydroxide) into 400 milliliters of deionized water, and slowly add 100 milliliters of 0.7 mol / liter CoSO 4 solution and 100 milliliters of 1.4 mol / liter sodium hydroxide aqueous solution, the pH of the resulting mixture is maintained at 11.4 to 11.6 during the addition of the aforementioned two solutions, producing nickel hydroxide particles deposited with cobalt hydroxide. The particles were separated by filtration, washed with 5 times the weight of deionized water three times, and dried under vacuum at 100°C. After passing through a 200-mesh sieve, spherical nickel hydroxide particles coated with a cobalt hydroxide layer with an average diameter of 10 microns and ...

Embodiment 2

[0077] This example illustrates the positive electrode active material provided by the present invention and its preparation method.

[0078] Nickel hydroxide particles coated with a cobalt hydroxide layer (containing CoOOH) were prepared according to the method described in Example 1, the difference being that, based on the weight of the nickel hydroxide particles, in terms of cobalt element, the hydrogen The content of cobalt hydroxide in the cobalt oxide coating layer was 3% by weight, and the average valence state of cobalt in the coating layer was 3.

[0079] Mix 1000 milliliters of 0.036 mol / L manganese chloride aqueous solution with 100 grams of nickel hydroxide particles coated with a cobalt hydroxide coating layer, and the manganese chloride aqueous solution contains 0.018 mole of disodium edetate. Under stirring conditions at 40°C, slowly add about 40 milliliters of 2 mol / liter sodium hydroxide aqueous solution, so that the resulting liquid maintains a pH of 10, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap