Assembling and positioning construction method of large steel casting members

A construction method and technology of steel castings, applied in building structure, processing of building materials, construction, etc., can solve problems such as difficulty in improving precision and inability to guarantee construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

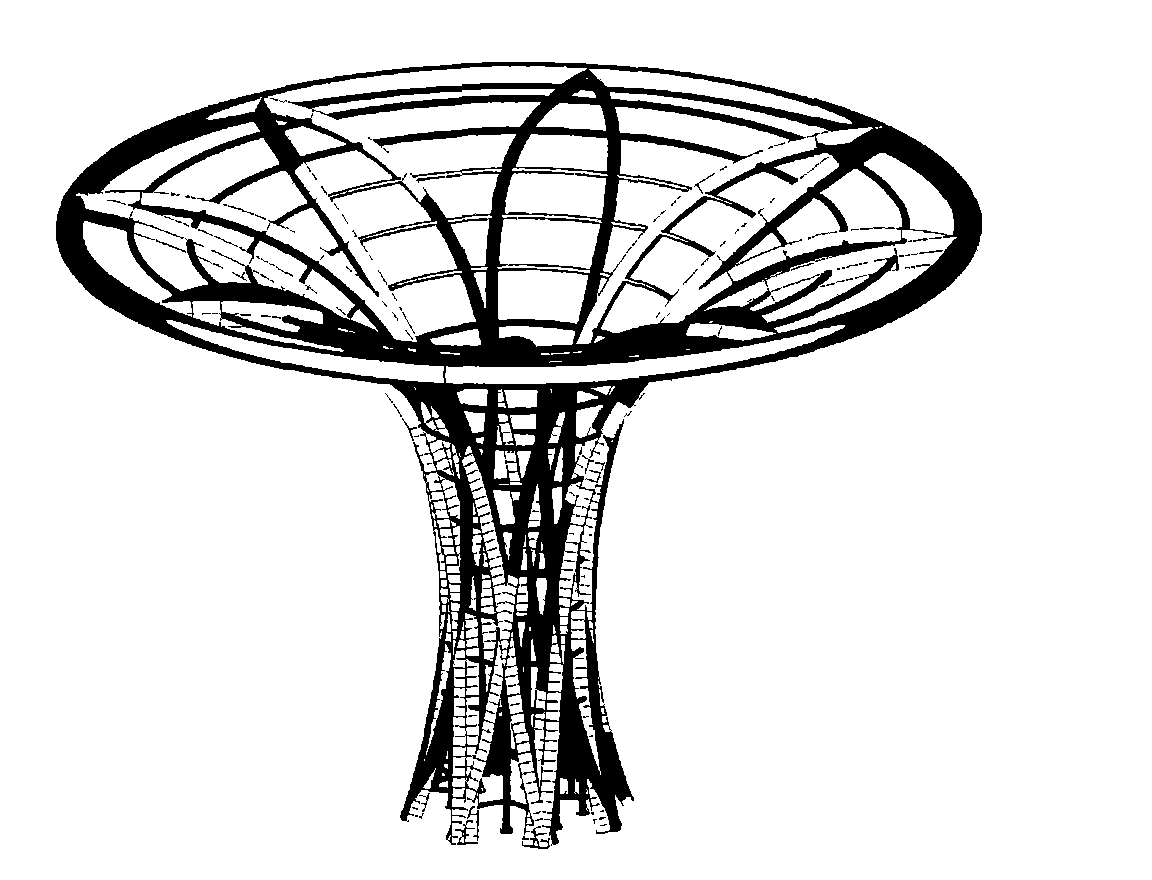

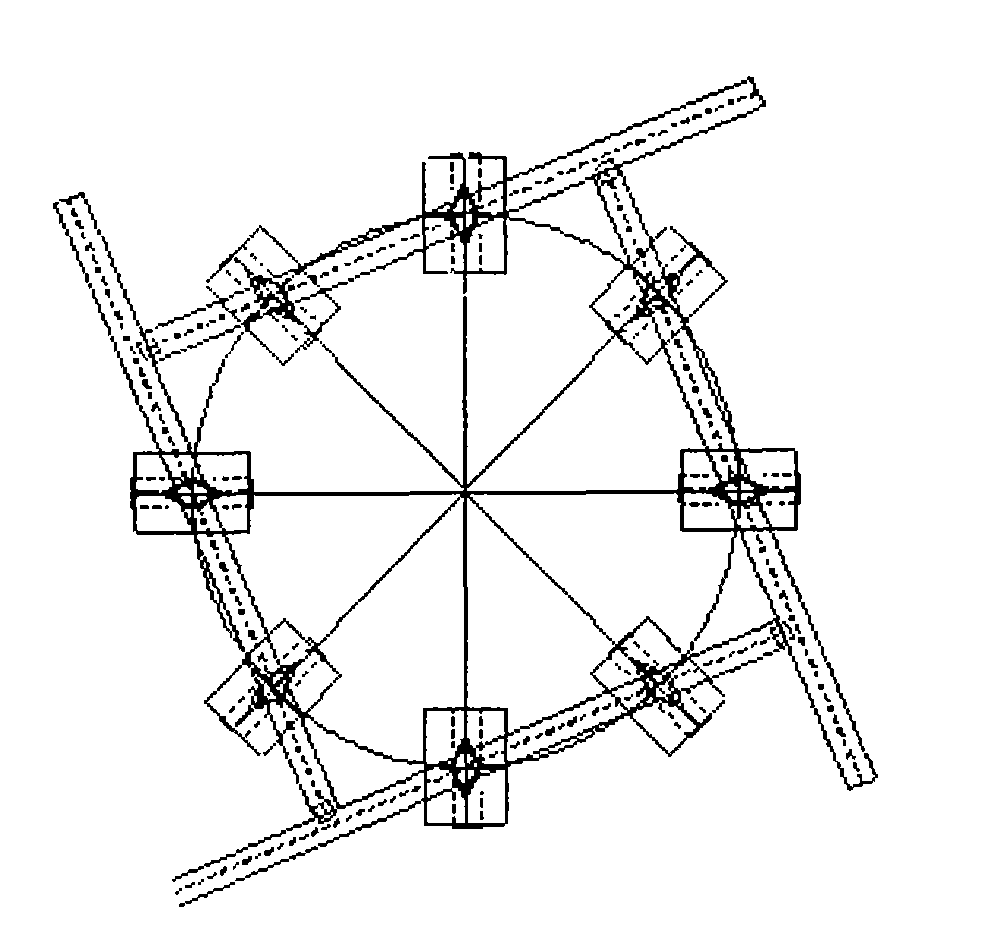

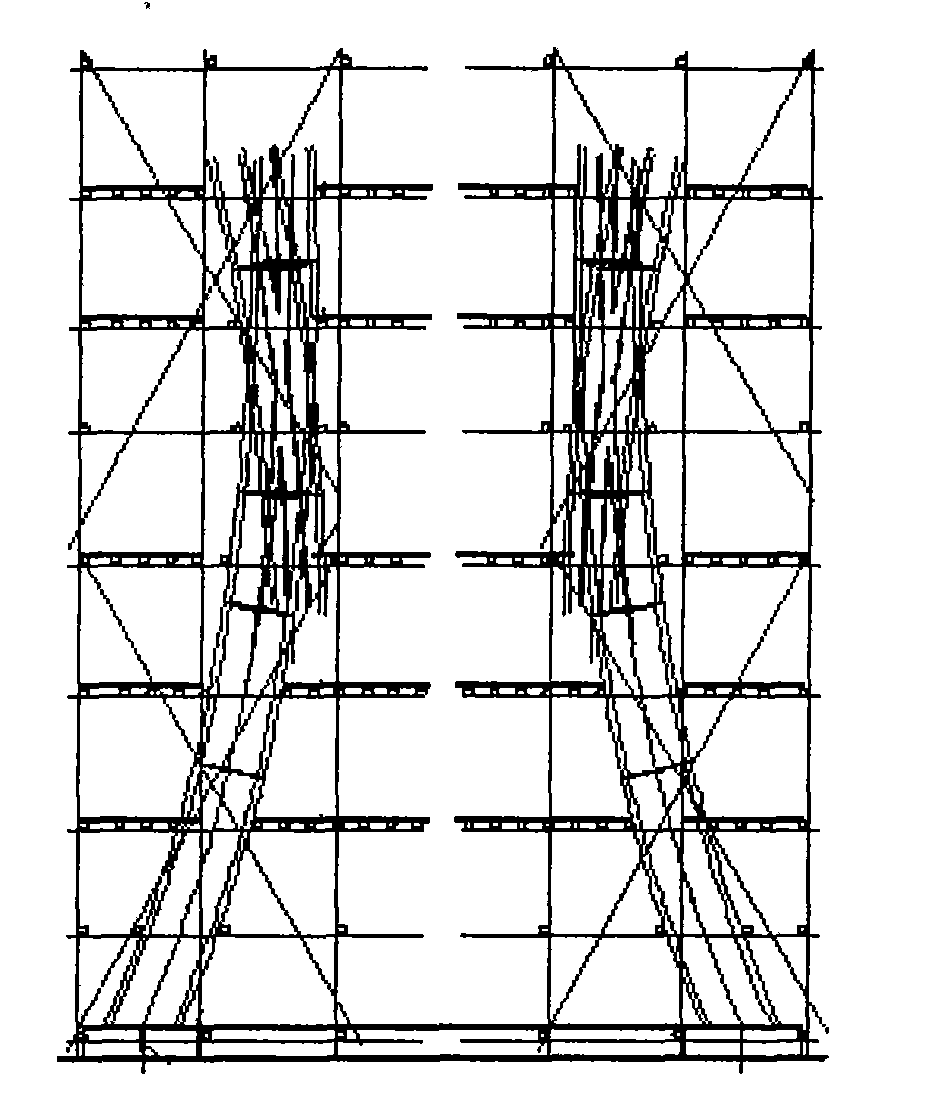

Image

Examples

Embodiment Construction

[0012] (1) For the pre-assembly of steel castings, lay steel plates in the effective area of assembly, fix the support on the steel plate and calibrate the projection coordinate position, place steel on the steel plate along the support, and connect them into a whole, (2) Set up a flat tire frame on the ground, assemble the adjacent steel castings on the ground, and weld the joint splicing plate, weld and install the lifting lugs at the appropriate positions on the surface of the steel castings, and weld the upper end of each steel casting (3) Set up the scaffolding first before assembling. The scaffolding is provided with a platform at the corresponding height. (4) Determine the position of the support node between the steel casting and the ground according to the size of the drawing, and project the first piece on the ground at the same time. The position of the uppermost inner point, (5) When the first section of cast steel members are in place, first select one of them as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com