Elevator system with automotive counterweight

A technology of equipment and elevators, which is applied in the directions of elevators, transportation and packaging in buildings, can solve problems such as cost, and achieve the effect of reducing complexity, less parts, and less maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

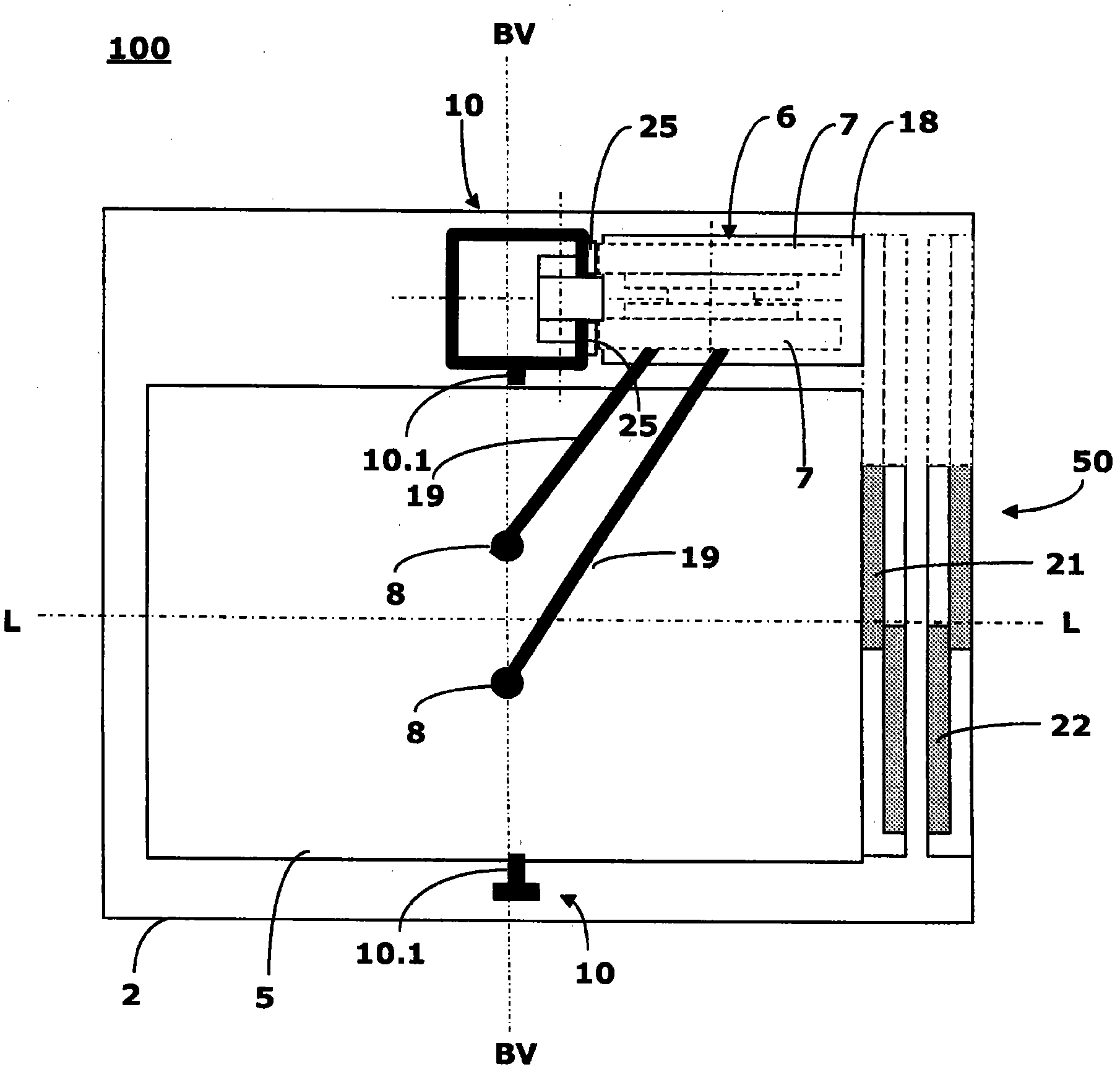

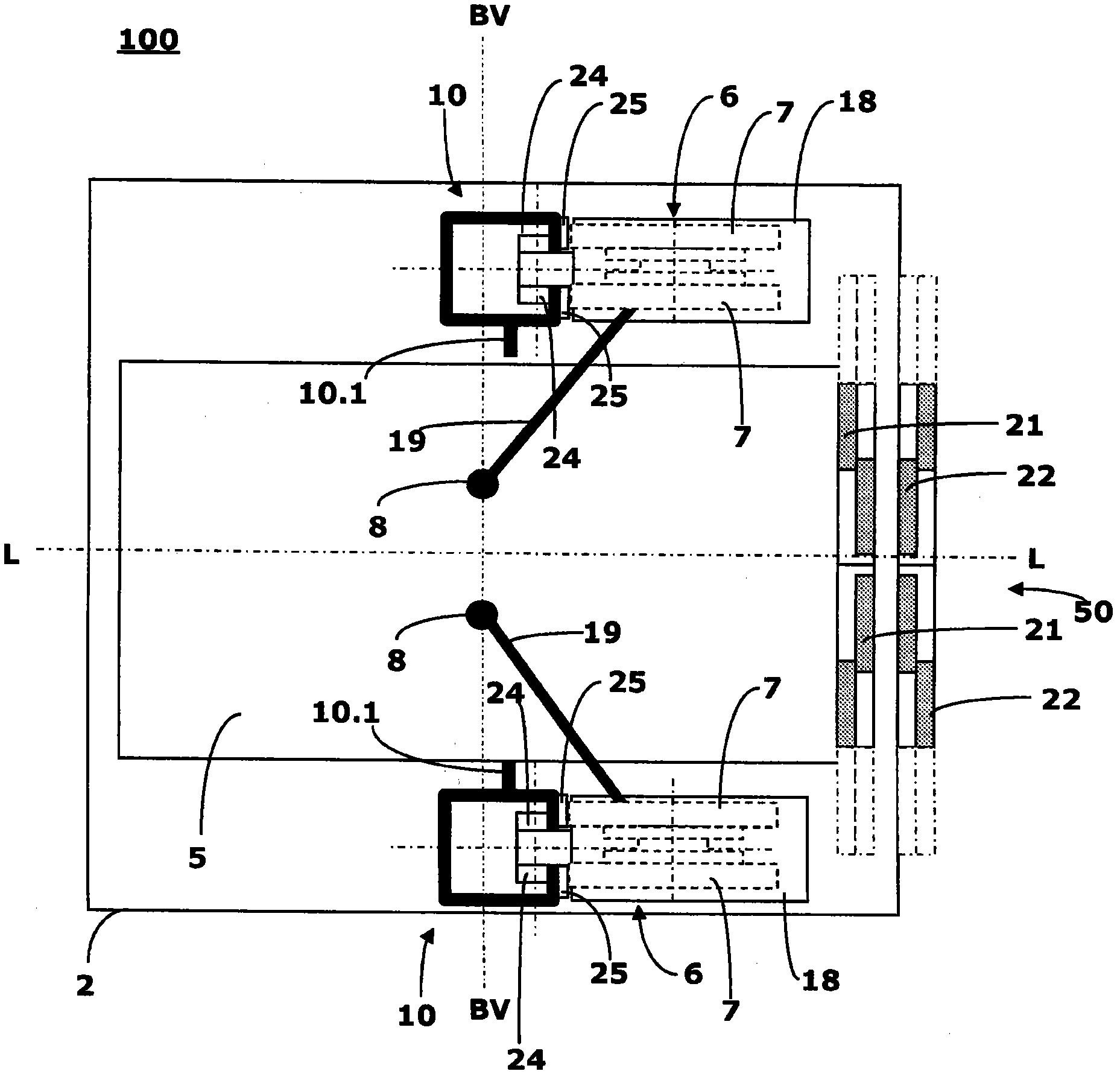

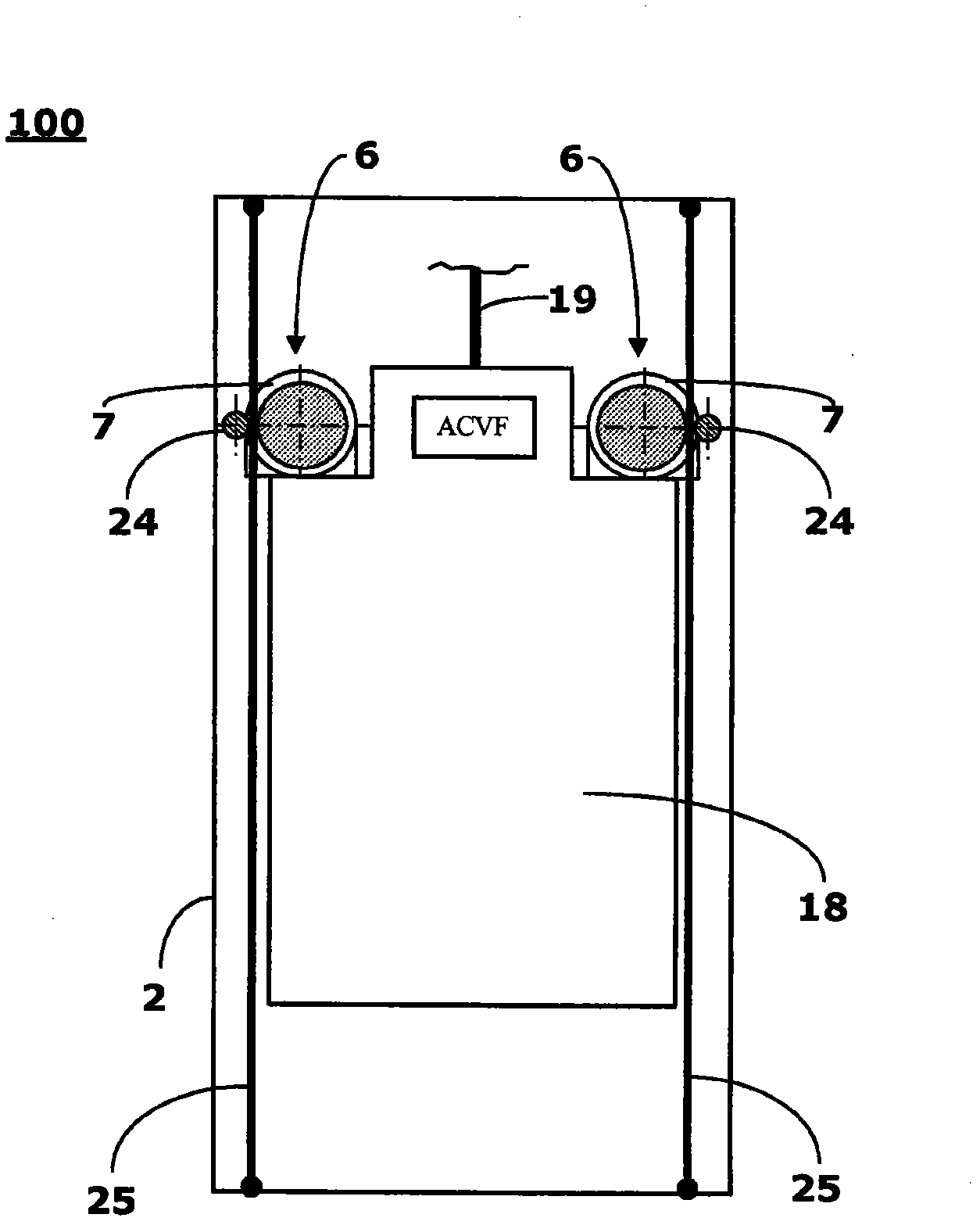

[0043] figure 1 The first elevator installation 100 according to the invention is shown. It involves an asymmetrical configuration because a guide structure 10 with a counterweight 18 is provided on one side of the elevator car 5, and the counterweight has a self-driving device. A simple guide rail (such as a T-shape) is provided on the opposite side of the elevator car 5, which is used as the guide structure 10. The elevator installation 100 can be installed, for example, in an elevator shaft 2 of a building. A flat driving device 6 is mounted on the counterweight 18, which is used as a self-driving device. The flat drive device 6 includes at least one gear ring 7 which meshes with complementary toothing 25, which is arranged on the guide structure 10 for example. The counterweight 18 is connected to the elevator car 5 through a bearing mechanism 19. The supporting mechanism 19 is preferably reversed via corresponding reversing wheels (for example, at the upper end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com