Magnetron sputtering target

A magnetron sputtering and target head technology, which is applied in the field of magnetron sputtering targets, can solve the problems of troublesome processing, single function, and cannot be sputtered vertically upward, and achieves a low processing cost, convenient space arrangement, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

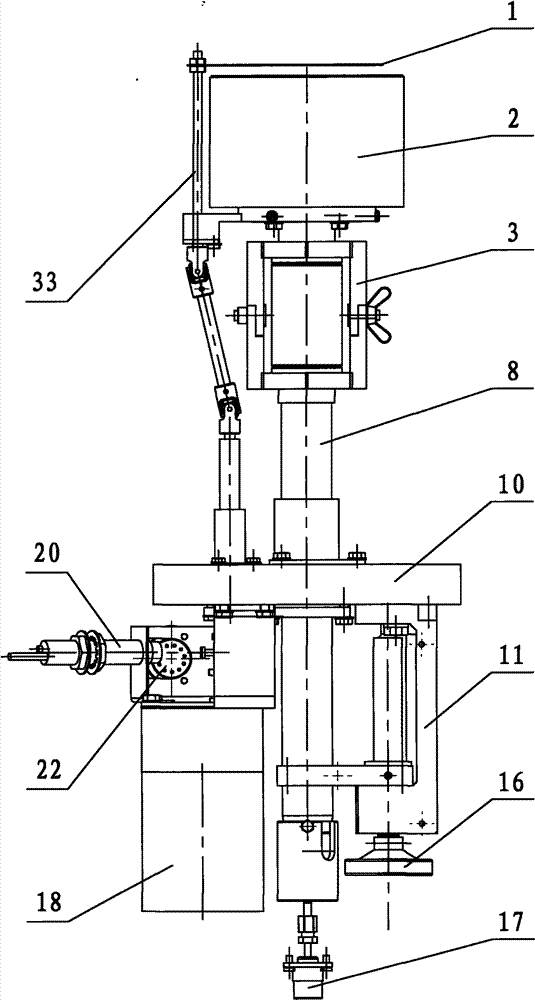

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

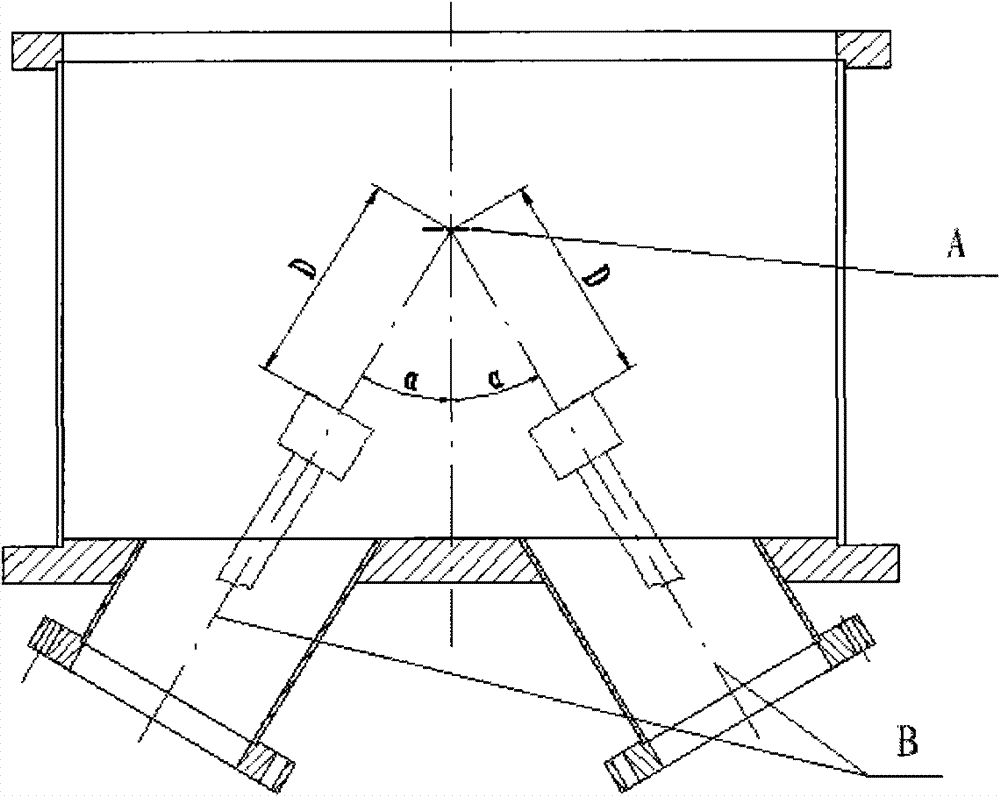

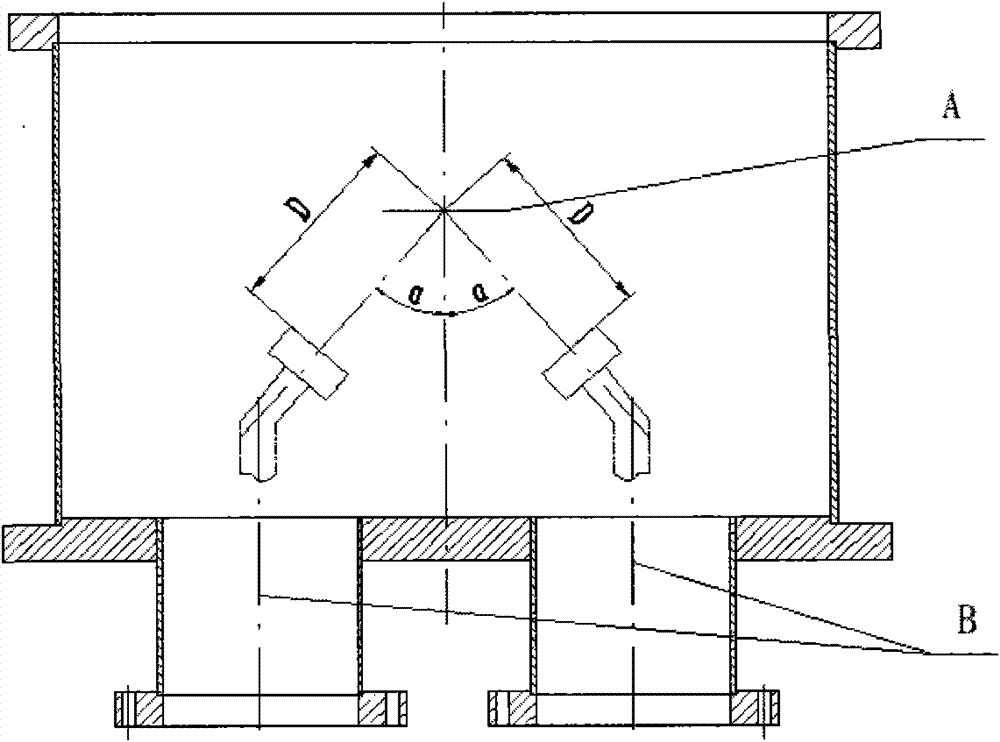

[0022] Such as Figure 3-5 As shown, the present invention includes a target head 2, a bending bellows assembly 3, a target support rod 8, a target support 10, a manual screw lifting assembly 11, a joint assembly 17, a driver 18 and a target baffle assembly 33, wherein the target support 10 is disc-shaped, on which the first and second guide seats 9, 25 are respectively arranged, and the target strut 8 can be reciprocally moved up and down and inserted on the first guide seat 9. One end of the target support rod 8 located above the target support 10 is connected to the target head 2 through a bent bellows assembly 3. The bent bellows assembly 3 includes a first nut 4, a bellows 7, and first and second bent plates 5, 6, the first and second bending plates 5, 6 can be a whole or composed of two parts with the same structure; when the first and second bending p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com