Magnetron sputtering coating workpiece table

A magnetron sputtering coating and workpiece table technology, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problems of low production efficiency and low degree of automation, and achieves easy operation and improved adhesion. power, improve the degree of automation of equipment and the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

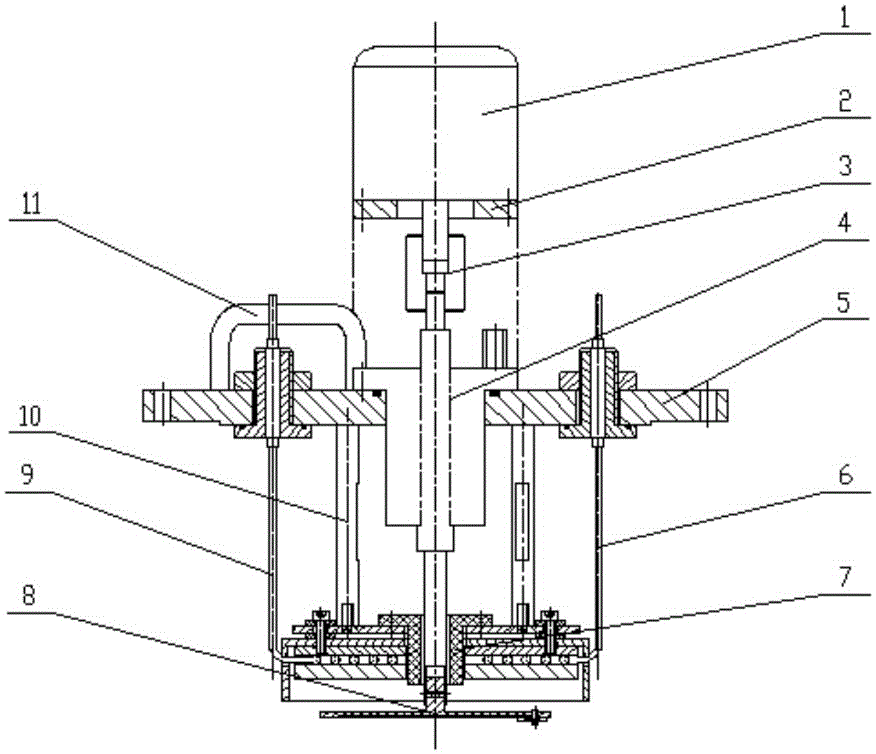

[0016] Such as figure 1 As shown, the magnetron sputtering coating workpiece table of the present invention includes a substrate table 8, a mounting flange 5, a heating body 9, a thermocouple 6 (such as a K-type thermocouple) and a speed regulating motor 1, and a substrate table 8 Used to install the substrate, the output end of the speed-regulating motor 1 is connected to the substrate table 8 through the coupling 3 and the magnetic fluid 4 and can rotate with the substrate table 8. By controlling the speed of the speed-regulating motor 1, the substrate can be The rotation speed of table 8 is adjusted. In this way, the substrate stage 8 can rotate and its speed can be adjusted (for example, the rotation speed adjustment range is 3-12rpm), thereby ensuring the uniformity of the sputtered metal film on the substrate, improving the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com