Steel bracket column used for factory

A technology for steel brackets and workshops, which is applied in the field of steel bracket columns, can solve problems such as high costs, and achieve the effects of saving economic costs, reducing calculation lengths, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

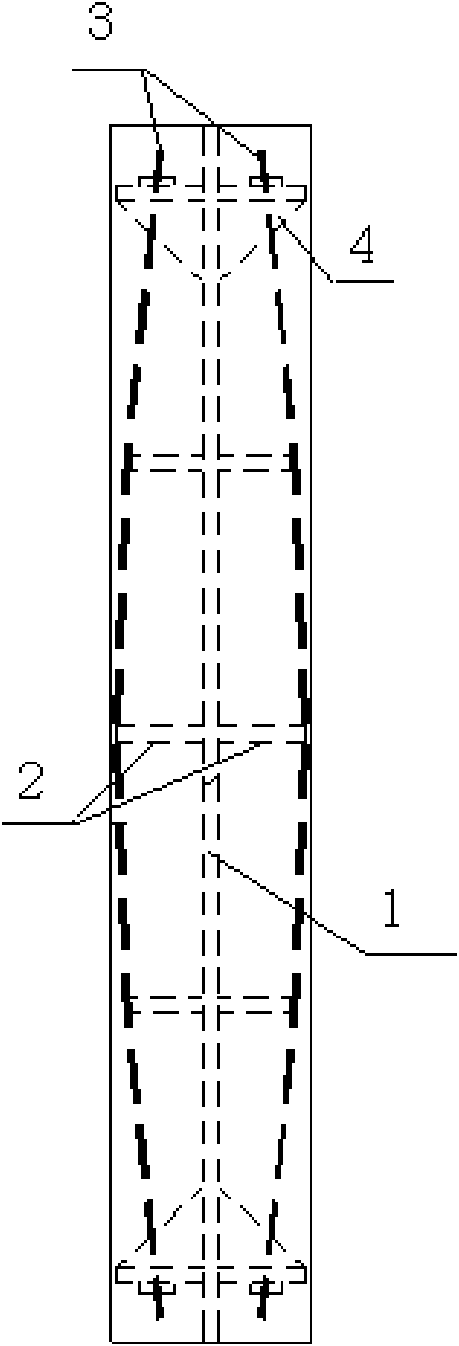

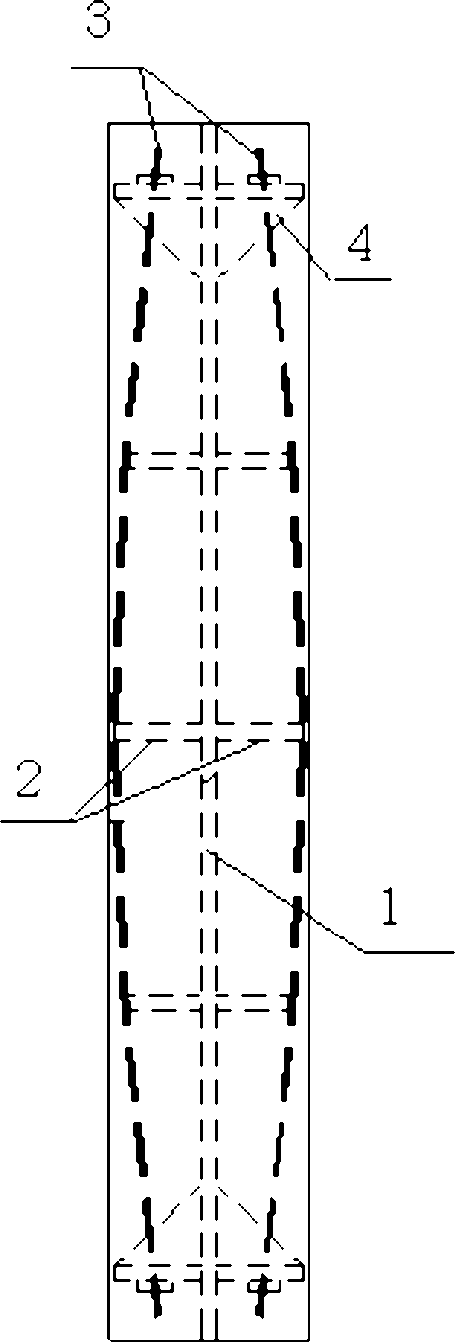

[0013] Embodiment 1 of the present invention: such as figure 1 As shown, the steel support column for a factory building of the present invention includes a web 1 of the steel support column. Three or more braces 2 are welded on both sides of the web 1, and the braces 2 on both sides are symmetrical with the web 1. And perpendicular to the plane where the web 1 is located; a pre-stressed member 3 is connected between the struts 2 located at the uppermost end and the lowermost end on each side of the web 1, that is, the two ends of the pre-stressed member 3 are anchored at the most by anchors. On the upper and lower struts 2.

[0014] A triangular steel plate 4 is fixed on the inner side of the uppermost and lowermost struts 2 to make the anchoring of the prestressed member 3 more stable.

[0015] The length of the struts 2 located between the uppermost end and the lowermost end is shortened from the middle to the two ends in turn, and their ends are all pressed against the prestre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com