Ball screw with backflow component

A ball screw and component technology, applied in belts/chains/gears, mechanical equipment, transmissions, etc., can solve the problems of increased manufacturing costs, poor processing, and high noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

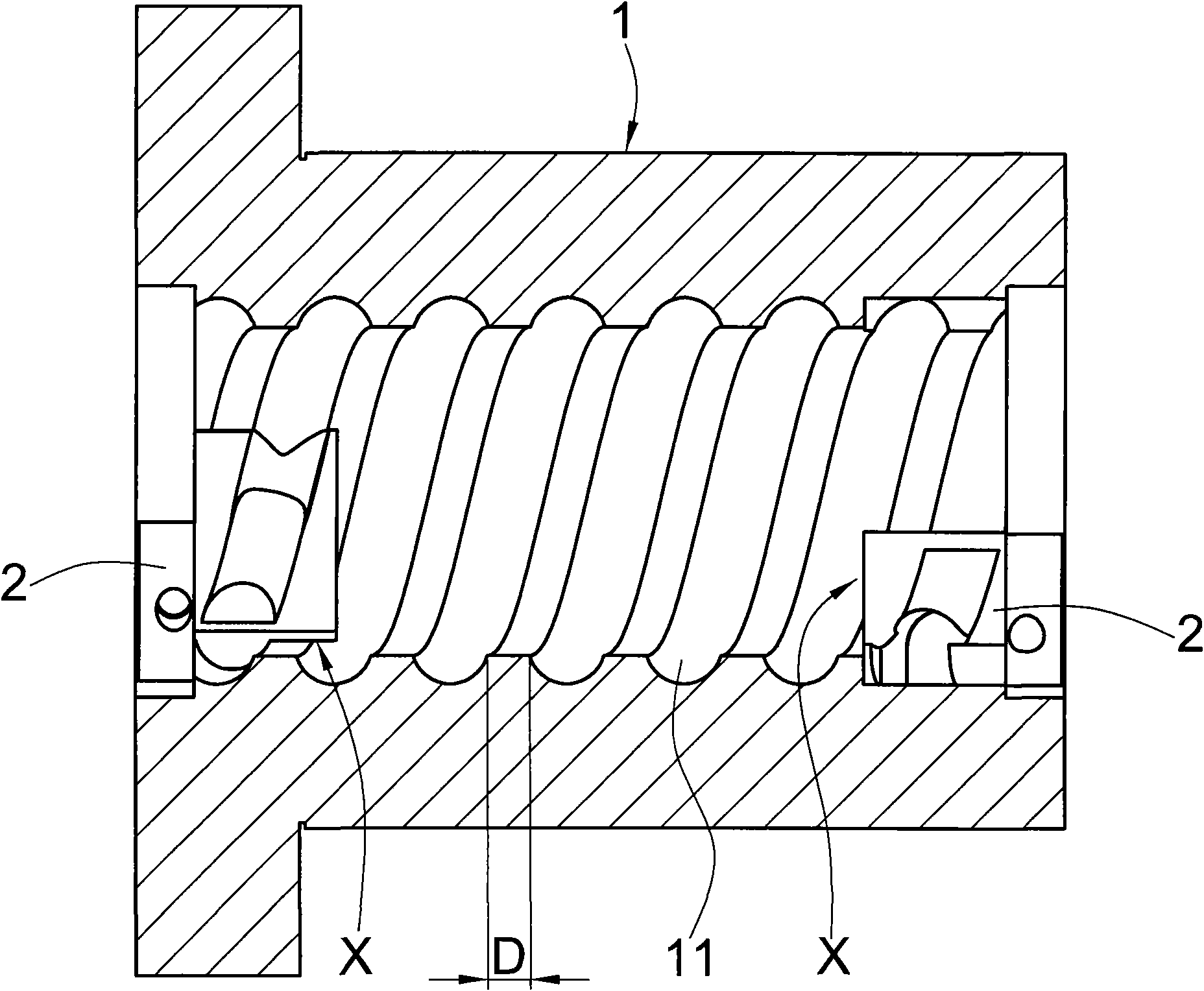

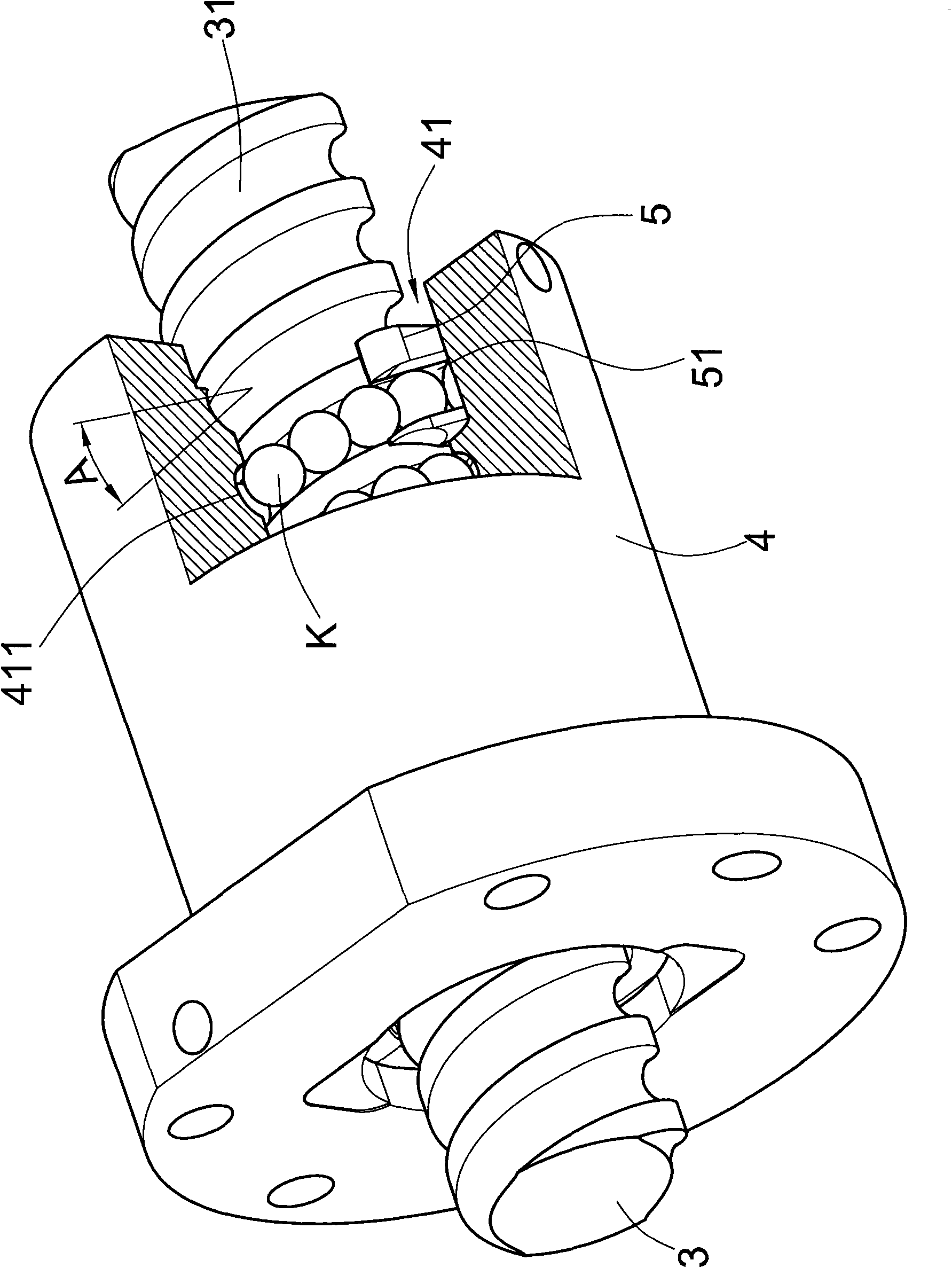

[0027] see Figure 2 to Figure 7 As shown, the present invention is a ball screw with a return assembly, which includes:

[0028] A screw 3, the outer edge of which is provided with a spiral rolling groove 31;

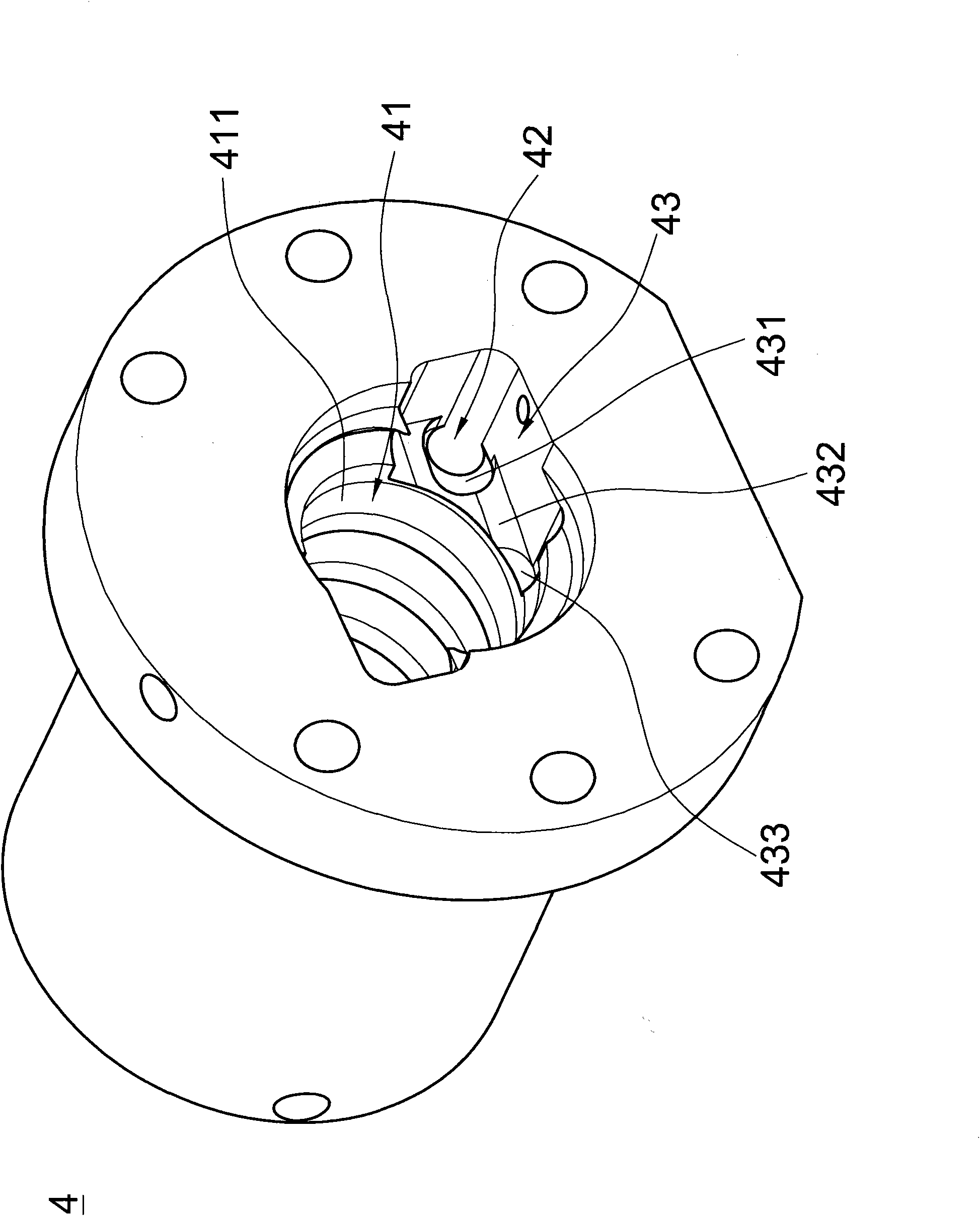

[0029] A nut 4, which is provided with a through hole 41 for the screw rod 3 to pass through, the inner edge of the through hole 41 is provided with a rolling groove 411 opposite to the rolling groove 31, and the rolling groove 411 and the rolling groove 31 form a load path , the load path has a lead angle A, and the nut 4 is provided with a return hole 42 that runs through both ends of the nut 4 in an axial direction, and a return hole 42 that is arranged at both ends of the return hole 42 and connects with the rolling groove 411 Mounting groove 43;

[0030] Two return components 5, which are arranged in the installation groove 43, the return component 5 is provided with a return channel 51, and the two ends of the return channel 51 are respectively connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com