Spiral parallel transmission line type line distribution measurement sensor for deformation and measuring method

A measuring sensor, spiral parallel technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measuring device, etc., can solve the problems of small deformation, high price, and the inability to identify the deformation position with a single measuring cable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

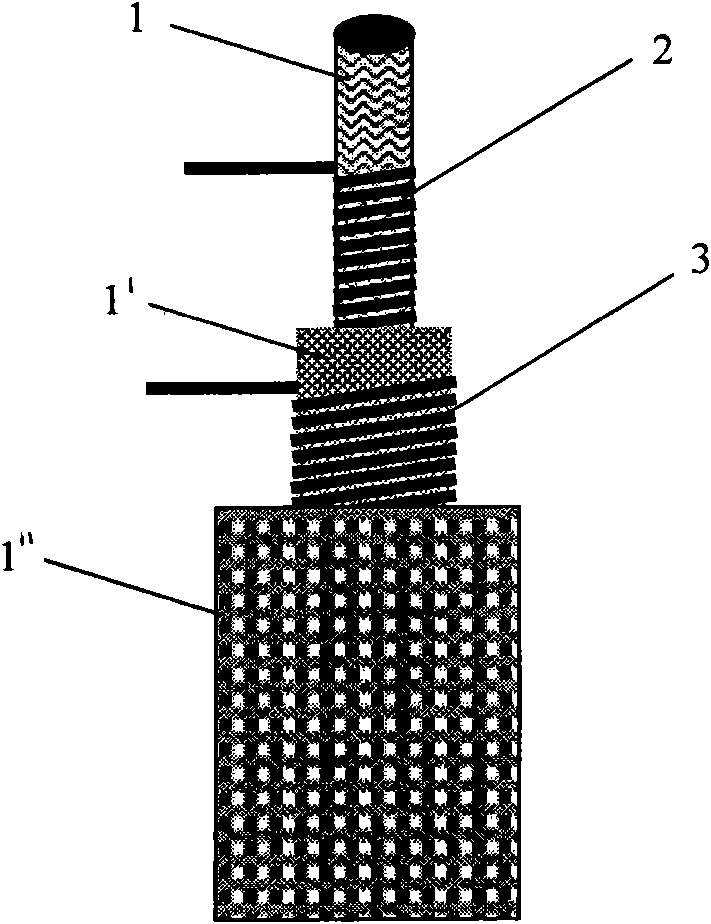

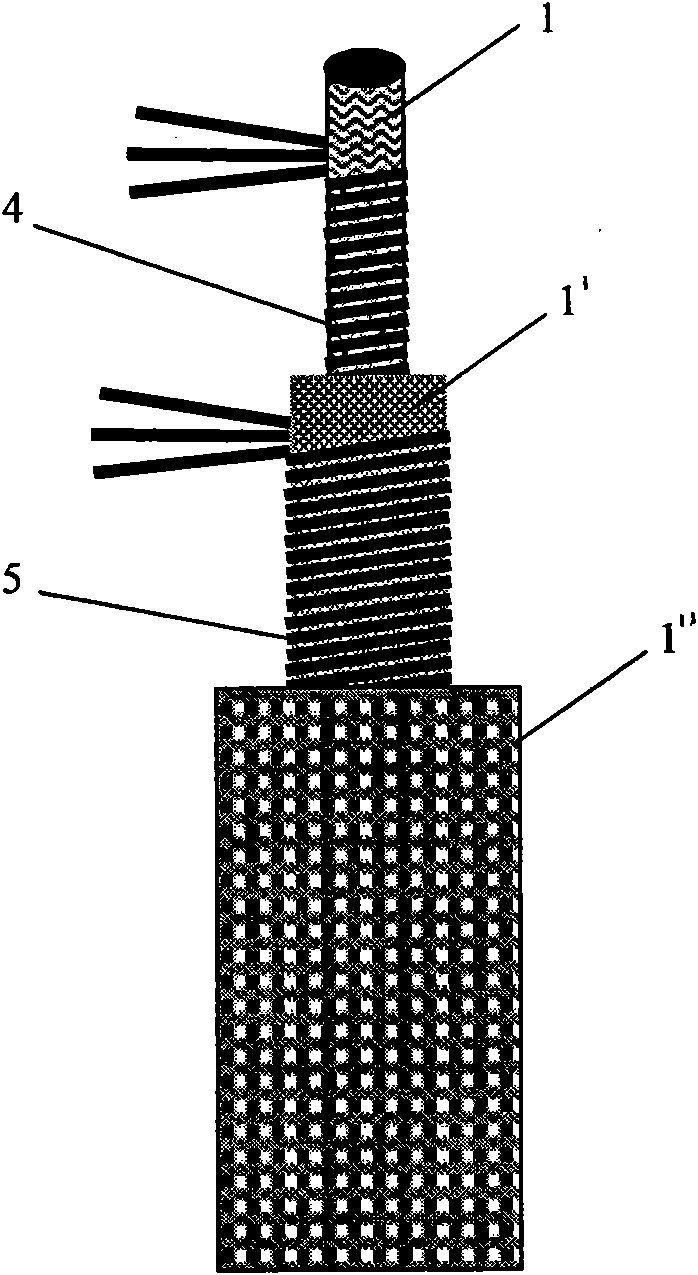

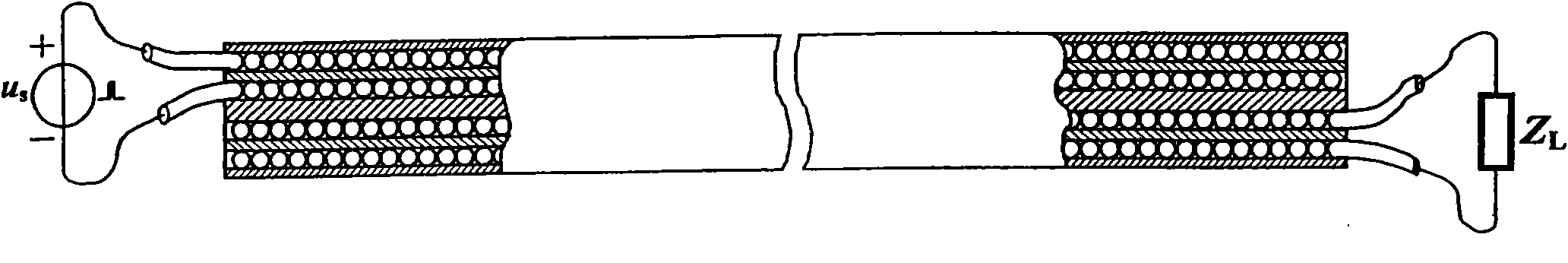

[0022] Such as figure 1 As shown, a single copper wire inner layer coil 2 is tightly wound on the outer cylindrical surface of a solid circular cross-section elastic rubber-plastic wire 1, and then a single copper wire inner layer coil 2 is wrapped with a solid circle The middle elastic rubber and plastic layer 1' of the same material as the cross-sectional elastic rubber and plastic wire 1 is wound on the middle elastic rubber and plastic layer 1' with a single copper wire with the same winding direction and the same wire spacing as the single copper wire inner layer coil 2 The outer layer coil 3 is wrapped with an outer elastic rubber-plastic layer 1″ of the same material as the solid round section elastic rubber-plastic wire 1 on the single copper wire outer layer coil 3, and the single copper wire inner layer coil 2 is connected with the single copper wire inner lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com