Modeling method and system for calculating energy efficiency of motor driven fluid transportation equipment

A technology of fluid transportation and motor drive, which is applied in the modeling method and system field of energy efficiency calculation of fluid transportation equipment, and can solve the problems of long period of energy contract management mode and incapable of real-time analysis of fluid transportation equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described below in conjunction with the accompanying drawings.

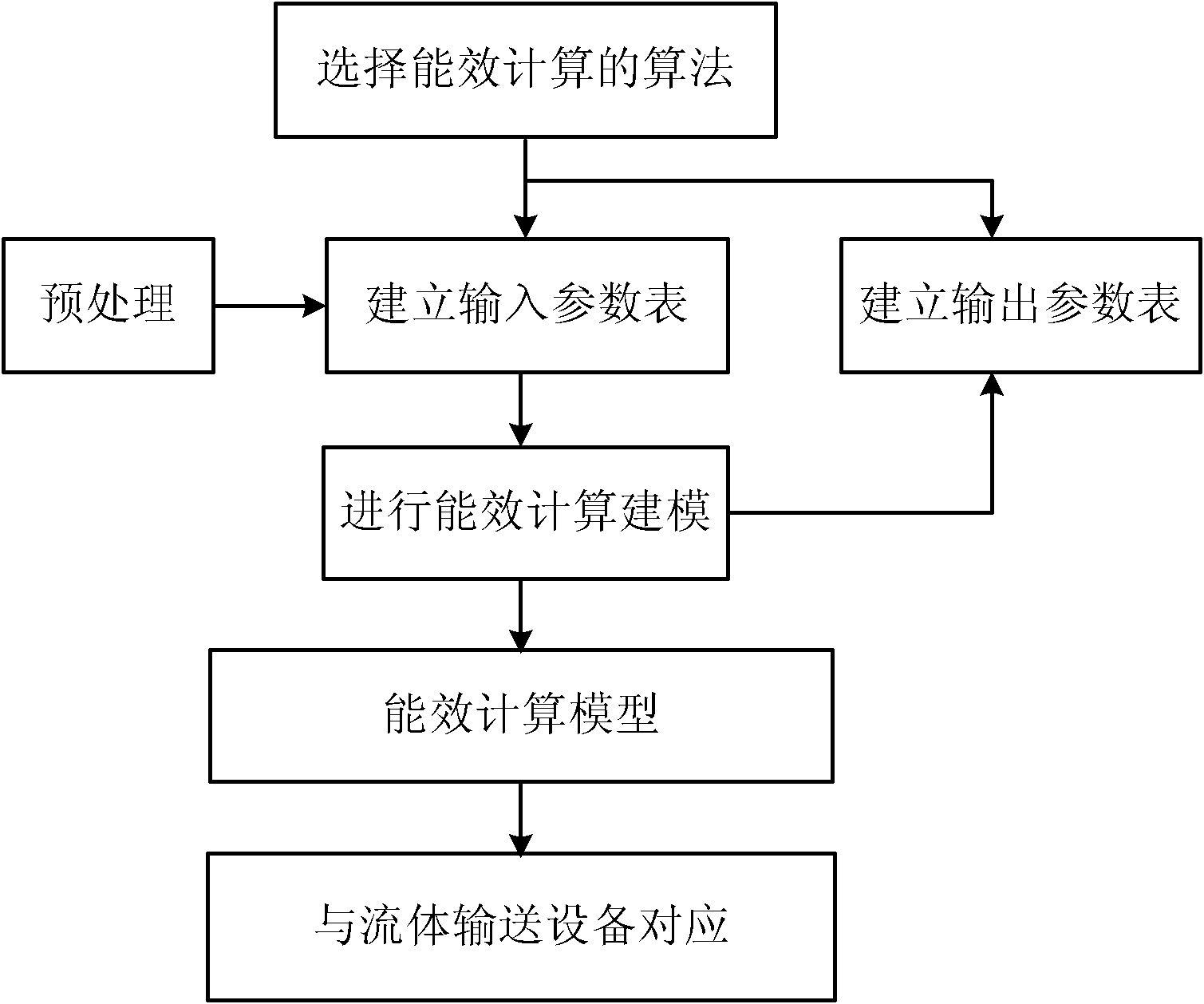

[0051] figure 1 It is a flow chart of the preferred modeling method for energy efficiency calculation of motor-driven fluid conveying equipment according to the present invention, and the steps of the modeling method are:

[0052] A. Select the algorithm for energy efficiency calculation according to the characteristics of fluid conveying equipment.

[0053] B. Establish an input parameter table and an output parameter table, wherein the input parameter table stores parameters used for energy efficiency calculation under the algorithm, including static parameters and production process parameters of the motor-driven fluid delivery equipment, and the output parameter table is used for storage As a result of energy efficiency calculation, the input parameter table and output parameter table established for each type of fluid conveying equipment adopt a fixed format. For example...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com