Iron core-free winding device

A technology without iron core and winding, applied in the direction of electromechanical devices, electric components, coils, etc., can solve the problems of waste of space, long end windings, no wire area, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0020] Before the present invention is described in detail, it is noted that in the following description, similar components are denoted by the same numerals.

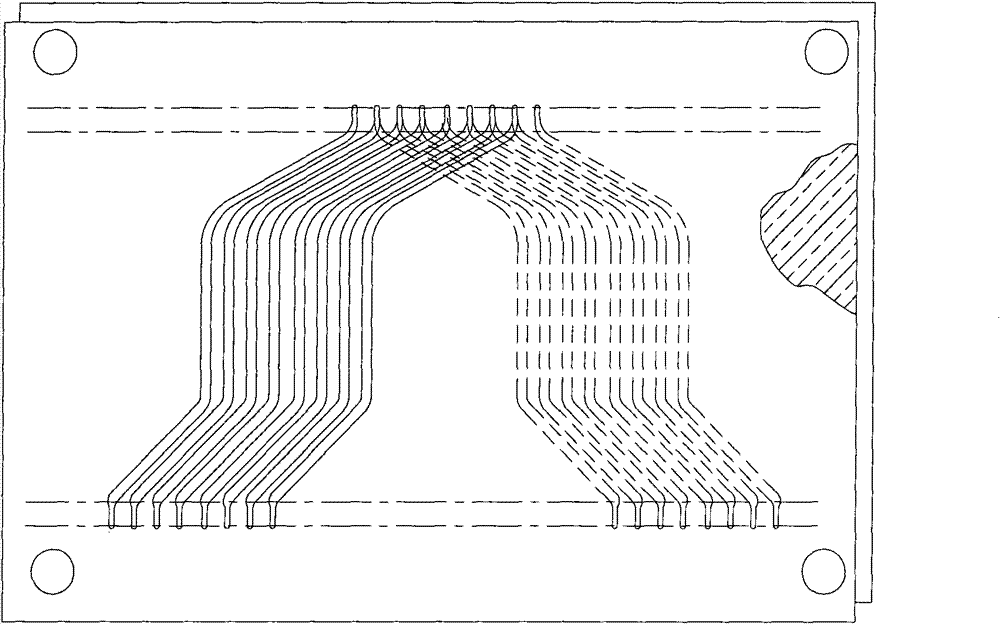

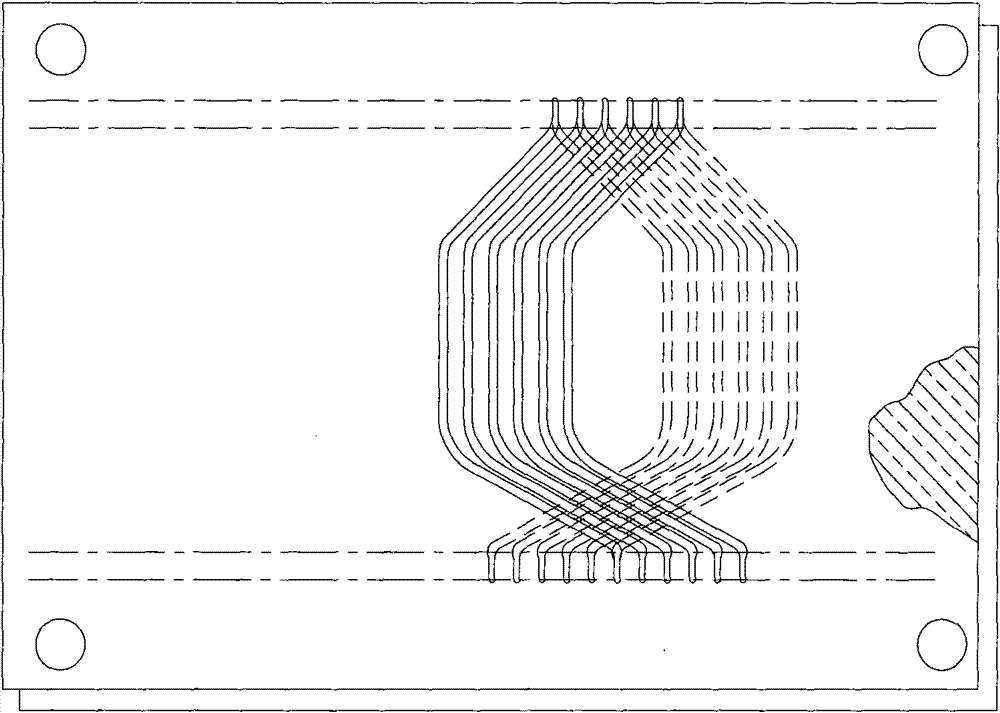

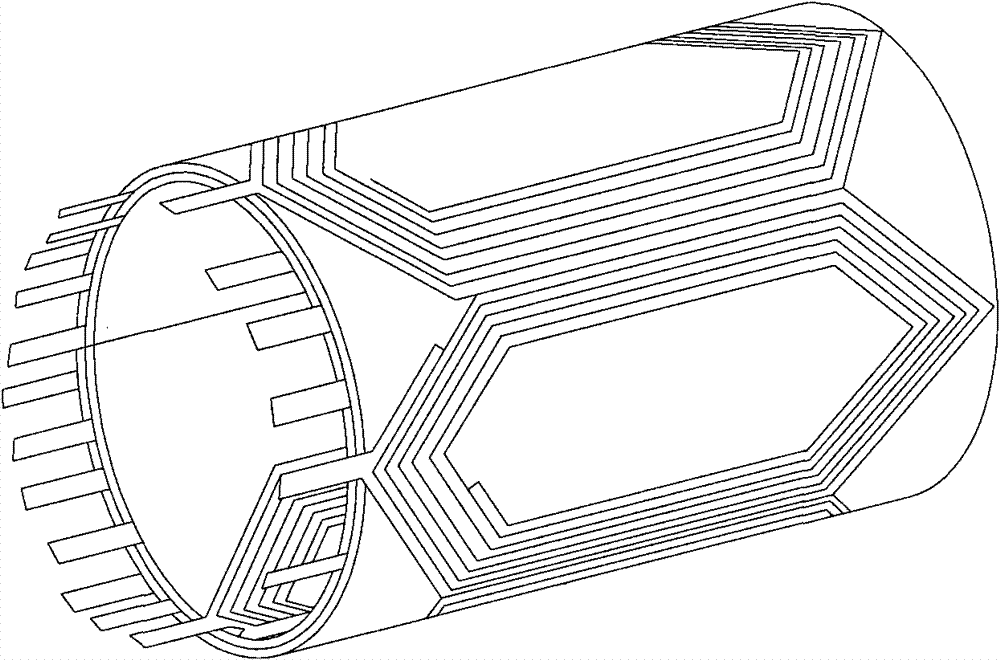

[0021] refer to Figure 5 , 6 , the first preferred embodiment of the ironless winding device of the present invention is applicable to a radial flux type ironless motor, and the ironless winding device includes a flexible substrate 3, a plurality of parallel first A winding 1, and a plurality of second windings 2 arranged side by side.

[0022] The flexible substrate 3 has an opposite first surface 34 (only shown in Figure 5 ) and a second side 35 (only shown on Image 6 ), a plurality of spaced apart first through holes 31 and second through holes 33, and a plurality of connectors 32 respectively extending in the first and second through holes 31 and 33. The two opening ends of each first throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com