Layer-by-layer overhanging structure lifting method

A hoisting method and overhanging technology, which is applied to special structures, building components, building structures, etc., and can solve construction problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

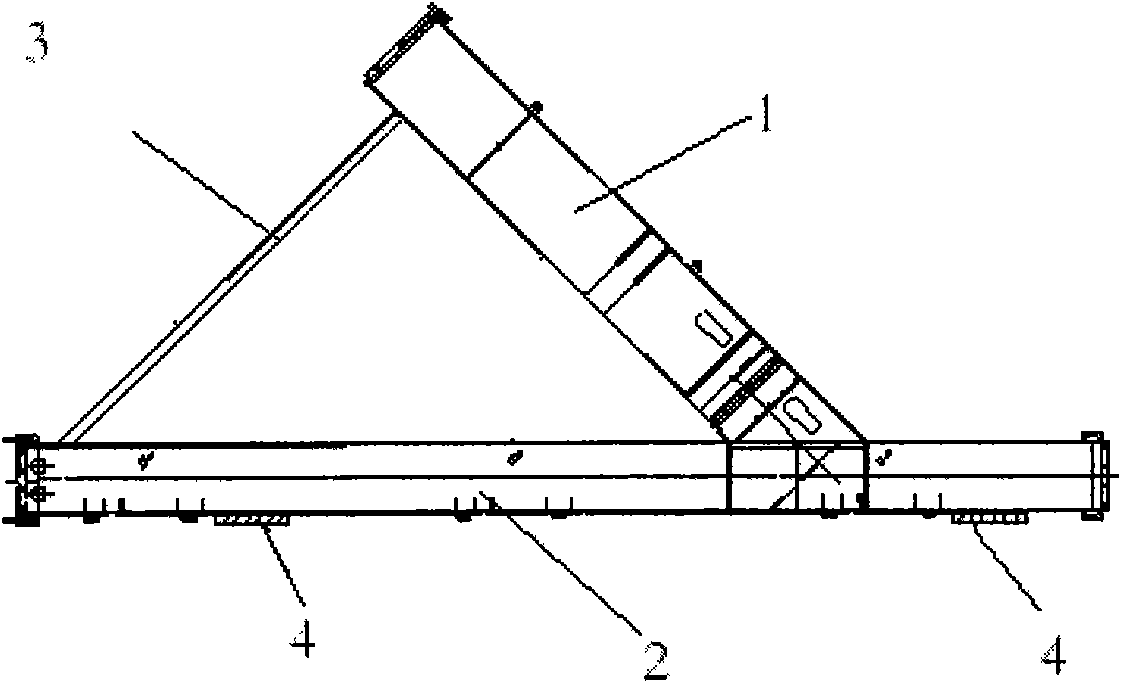

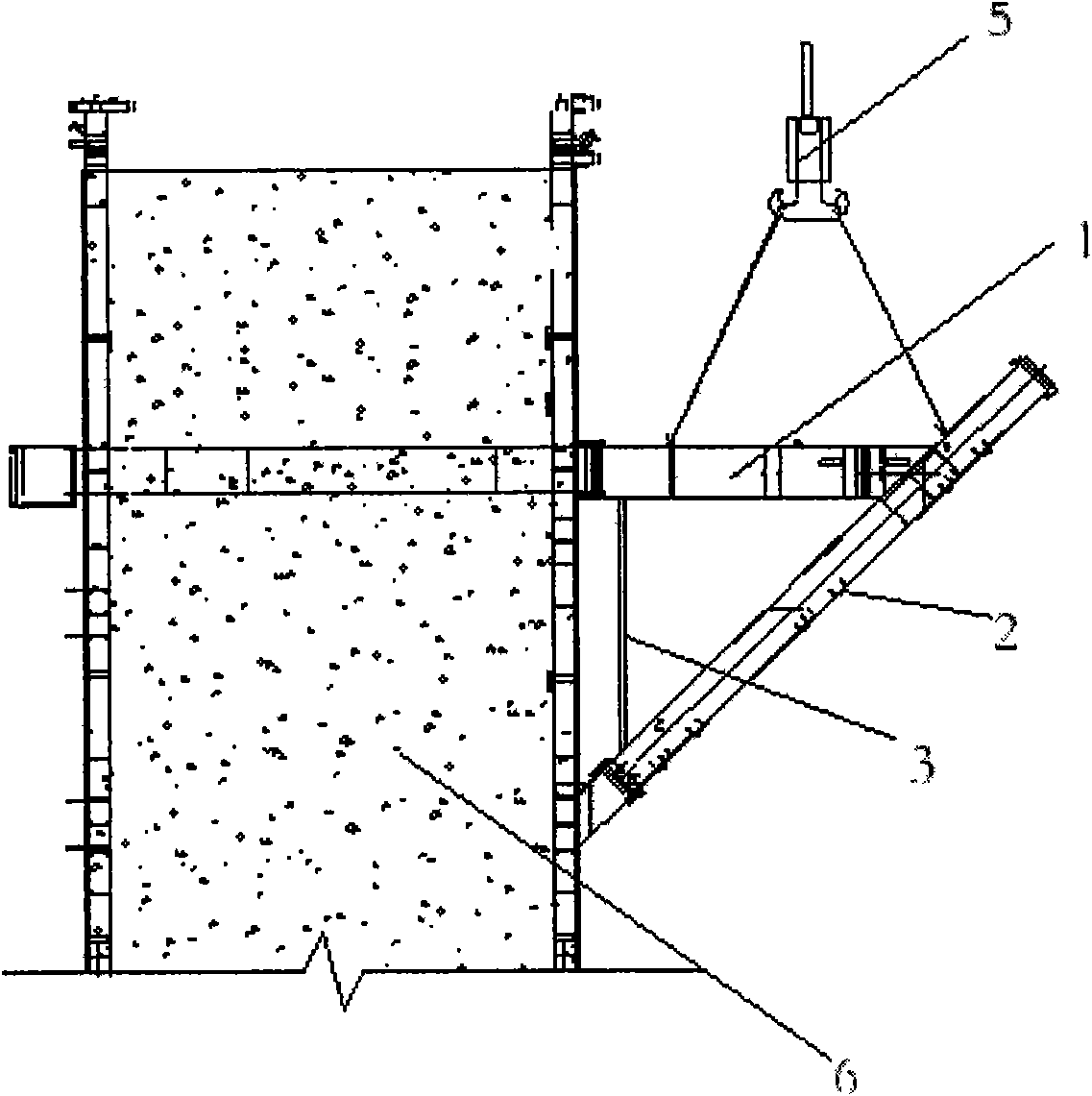

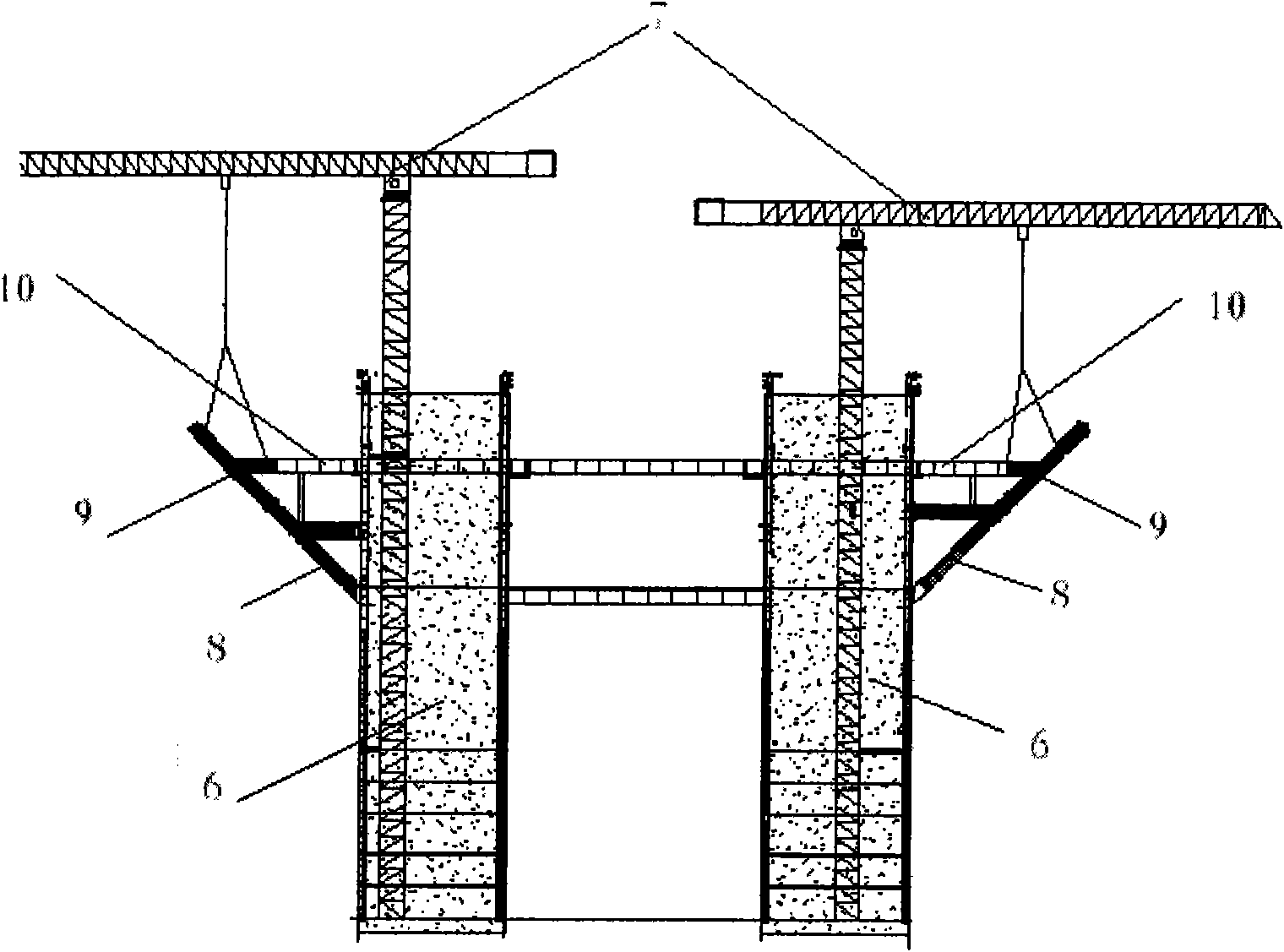

[0007] The entire large cantilever structure is decomposed layer by layer according to the structural characteristics, and then the cantilever segmented structure decomposed layer by layer and the relevant steel beams on the floors are combined into several hoisting units, and temporary rods are installed on each hoisting unit Reinforce the connection, hoisting is carried out layer by layer from bottom to top, first hoist the hoisting unit of the bottom cantilever segment structure, and make a fixed connection with the building, after the installation of the bottom cantilever segment structure is completed , then hoist the hoisting unit of the sub-lowest cantilevered sub-structure, and fix it with the cantilevered sub-structure of the lowest level and the steel beams of the relevant floor structure, and repeat the above steps until the cantilevered sub-structure of the highest level is installed, and finally removed Temporary reinforcements. It is characterized in that the hoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com