Fast moving and fixing device of anchor rod machine of roadway floor of coal mine

A technology for coal mine tunnels and fixing devices, which is applied in the installation of bolts, mining equipment, earth-moving drilling, etc., can solve the problems of poor positioning of drilling rigs, low work efficiency, heavy equipment weight, etc. good work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

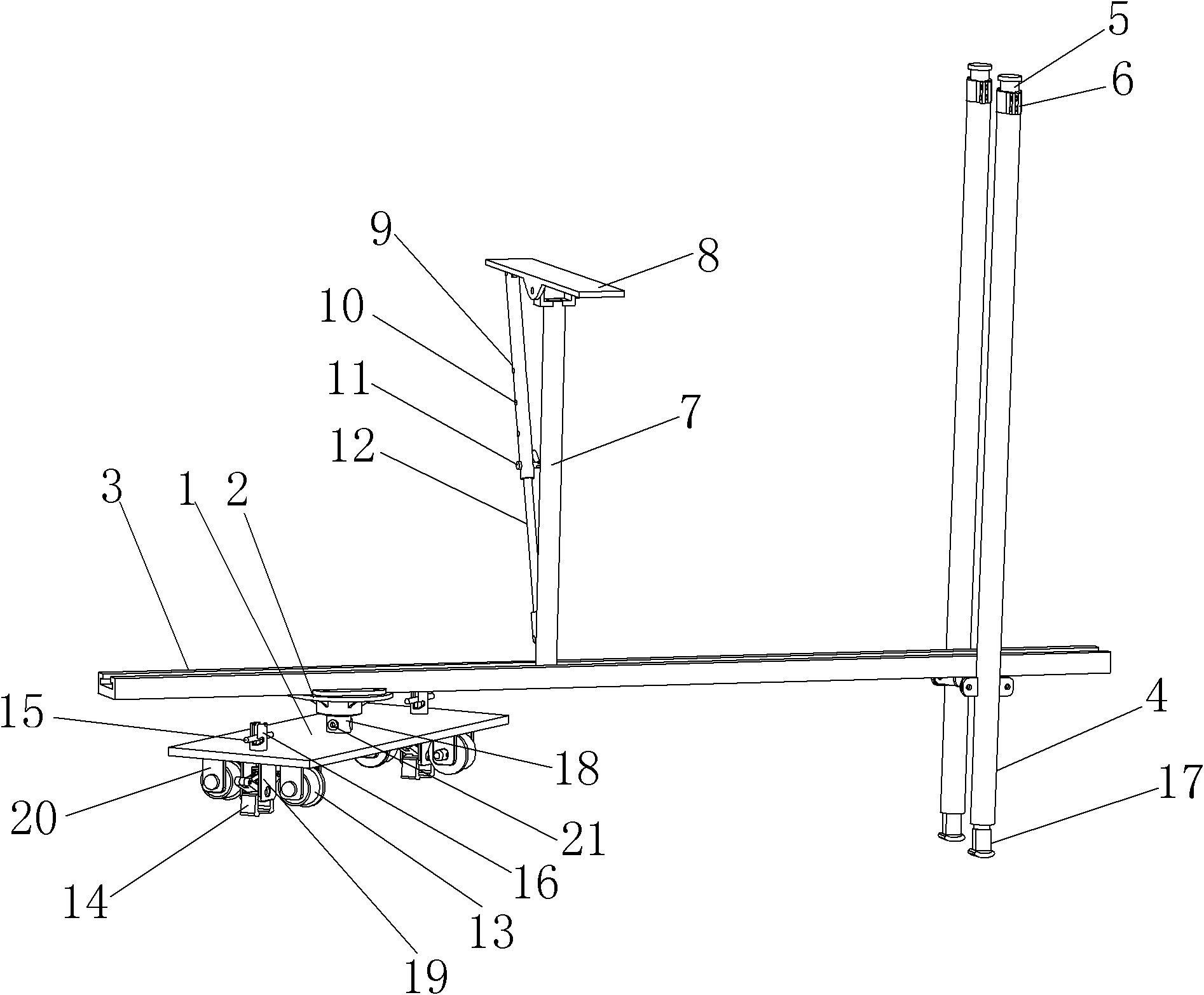

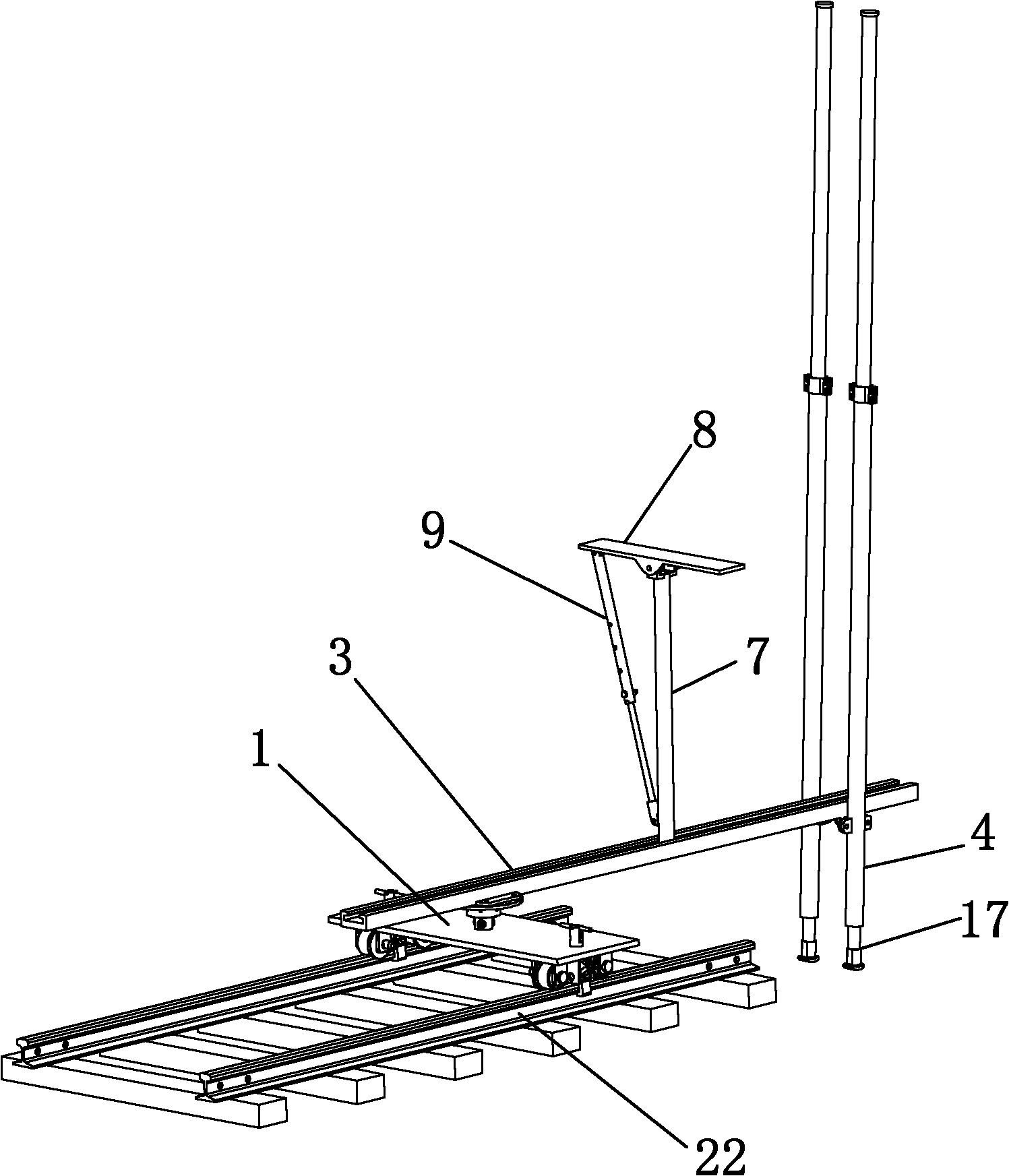

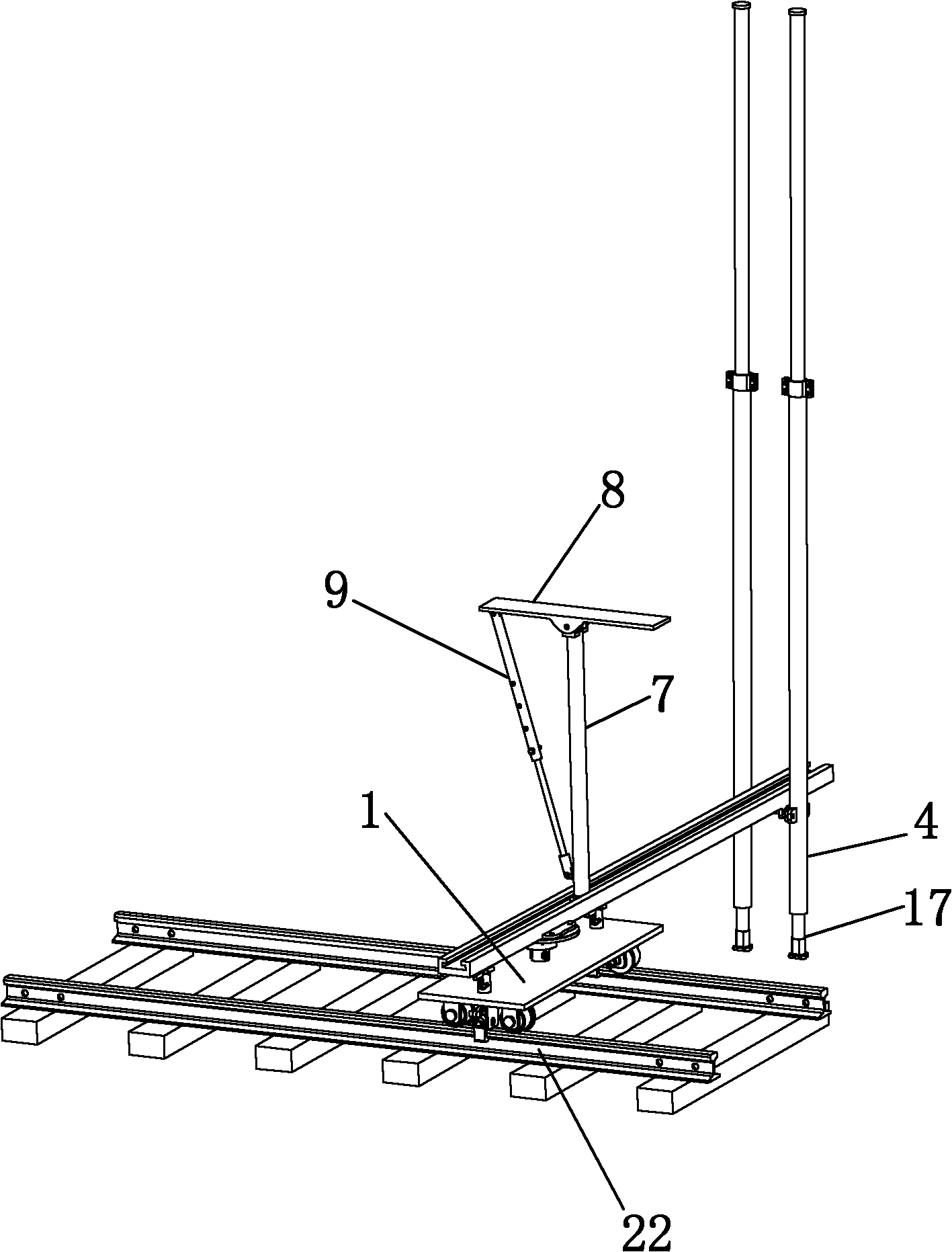

[0011] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] Such as Figure 1-Figure 3 As shown, the present invention includes a base, a guide rail, a support column and a bolter bearing platform, four pairs of rolling wheel ears 20 on both sides of the bottom of the base 1 respectively have rolling wheels 13, and a turntable 2 at the upper central position for carrying the guide rail 3 , the guide rail 3 rotates 360° with the turntable 2 as the center, and two pairs of quick brake caliper ears 19 at the middle positions on both sides of the base 1 are respectively equipped with a quick brake caliper 14 controlled by a pull rod 15, and there is a bottom plate anchor on the guide rail 3. The bearing platform is connected with the guide rail 3 through the support rod 7. The far end of the guide rail 3 has a telescopic combined support column composed of the column foot 17, the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com