Megawatt-stage vertical shaft wind power generator with adjustable attack angle

A wind power generator, megawatt-level technology, applied in the field of vertical axis wind power generators, can solve problems such as poor environmental adaptability, low wind energy utilization rate, complex blade shape, etc., and achieve easy maintenance, easy installation, and low operating costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention will be further described below in conjunction with the accompanying drawings, but not as a limitation of the present invention.

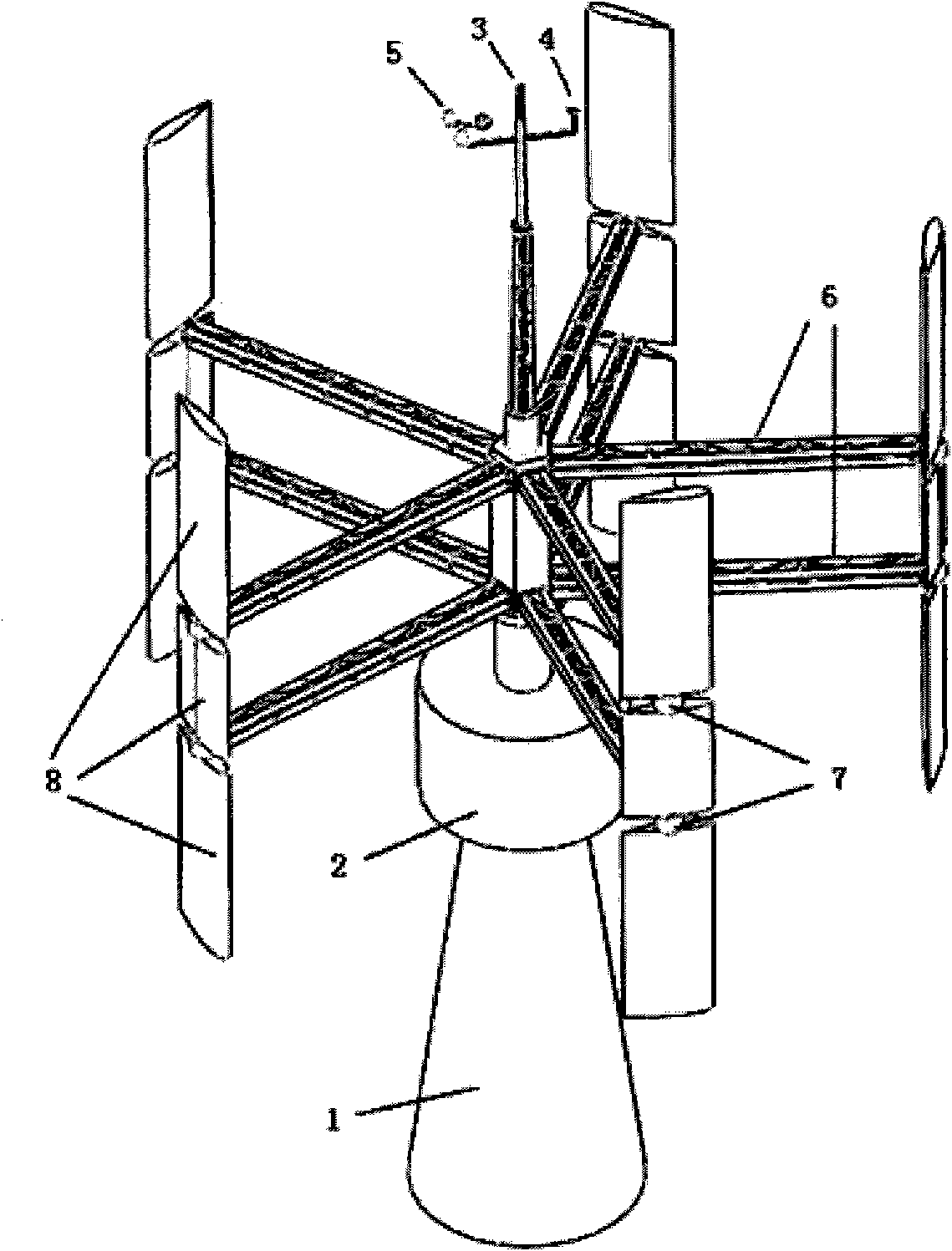

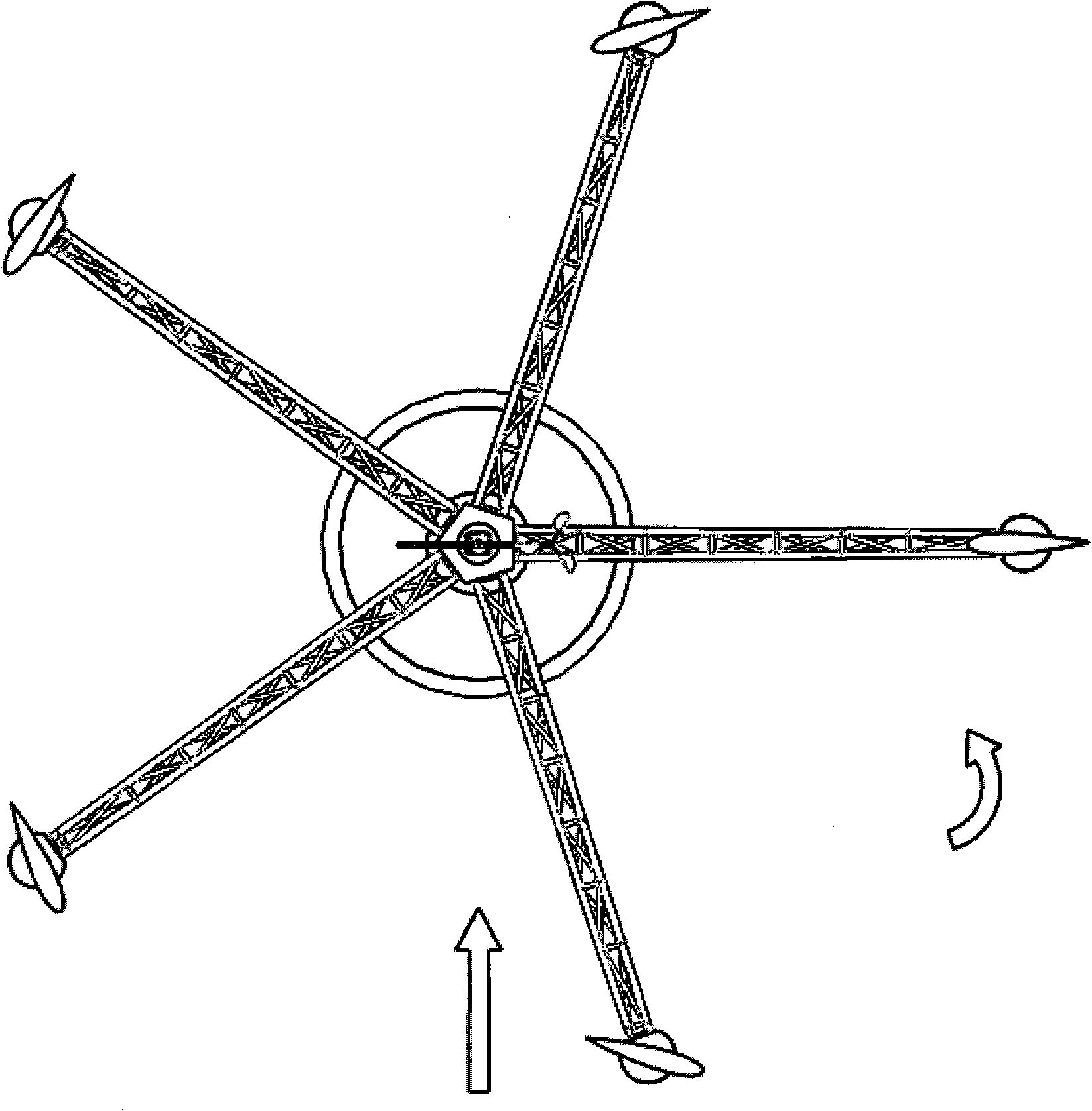

[0022] The structure of this embodiment is as described above, combined with figure 1 , the main vertical shaft 1 of the present invention is fixed on the ground, the wind vane 4 and the anemometer 5 can rotate freely relative to their respective axes according to the actual wind direction, and the large blade 8 composed of a cantilever beam 6, a blade rotation device 7 and other accessories can be driven by the wind Under the action, it rotates independently relative to the main vertical shaft, and transmits the kinetic energy to the generator set 2, and the kinetic energy is converted into electrical energy by the generator.

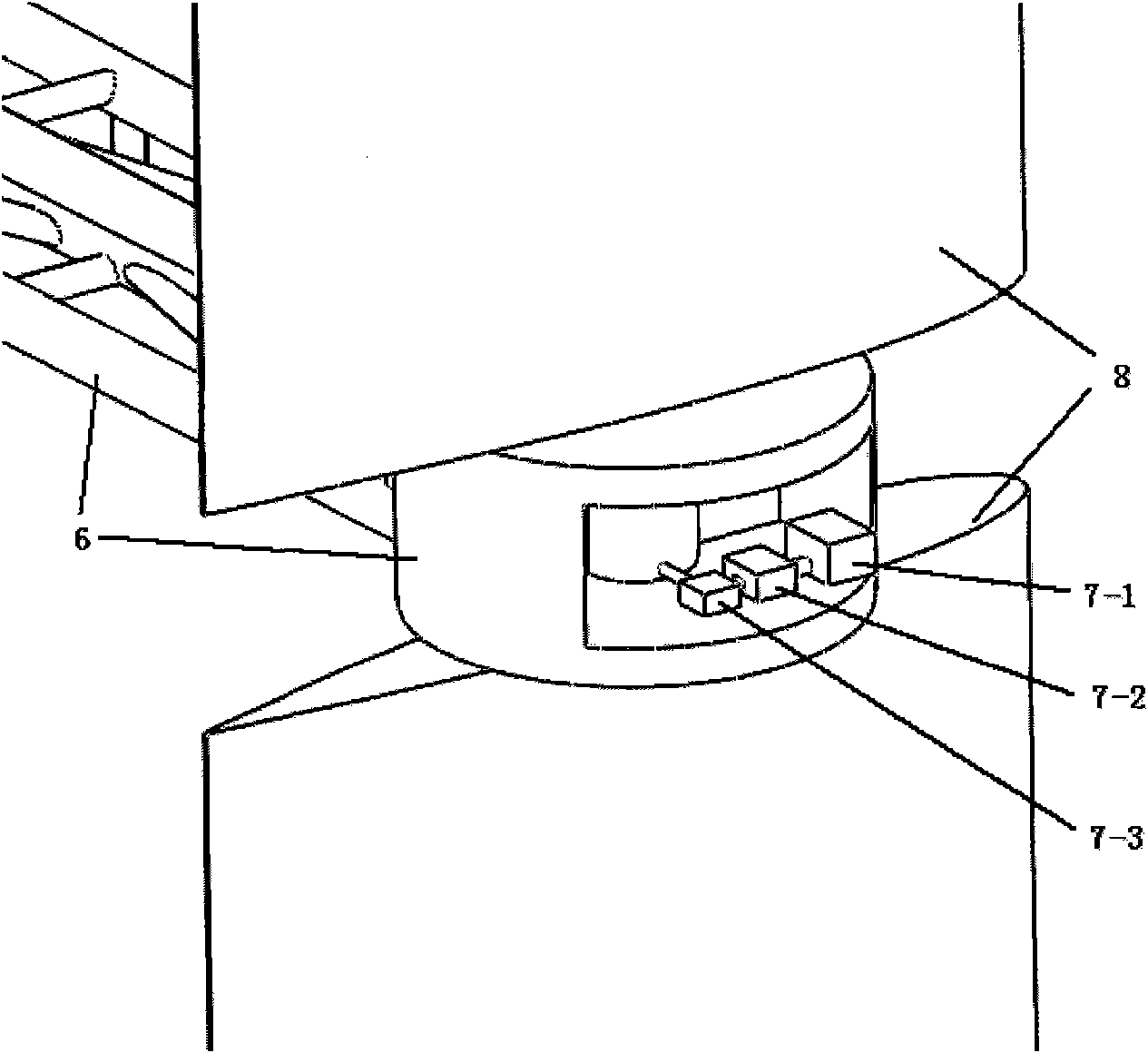

[0023] combine figure 2 , the blade rotation device 7 is described as follows: the pitch motor 7-1, the worm reduction box 7-2 and the pitch mechanism 7-3 with self-locki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com