Non-programming numerical control lathe

A CNC lathe and data technology, which is applied in the direction of program control, computer control, general control system, etc., can solve the problems of enterprise personnel and financial loss, affect the normal production of enterprises, poor work stability, etc., achieve ultra-low employment threshold, improve Mental outlook, the effect of reducing processing and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

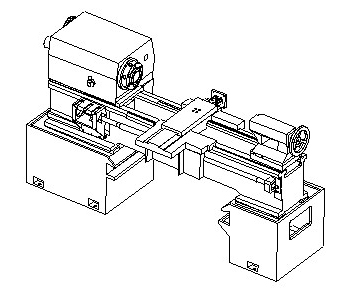

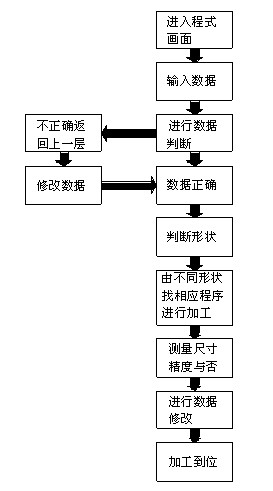

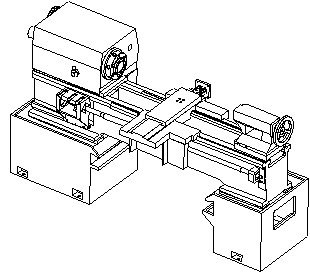

[0009] Embodiment 1: with reference to attached figure 1 and 2 . A non-programming numerically controlled lathe, which includes a numerically controlled lathe, the signal terminal of the computer in the numerically controlled lathe is connected to the signal terminal of the menu-type data display screen, the computer has built-in software for automatic identification and forming of technical drawings, and the signal output terminal of the computer passes through the data line Connect to the signal input terminal of the drive circuit, and connect the signal output terminal of the drive circuit to the lathe electrical controller. The program screen in the technical drawing automatic recognition forming software receives the data input of the processed product, and judges the data of the processed product: (1) If the data is correct, enter the shape judgment program; (2) If the data is incorrect, return to the upper layer and perform data modification , after the modification i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com