Lead-acid storage battery formation charging and discharging method

A lead-acid battery, storage battery technology, used in secondary battery charging/discharging, secondary battery repair/maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

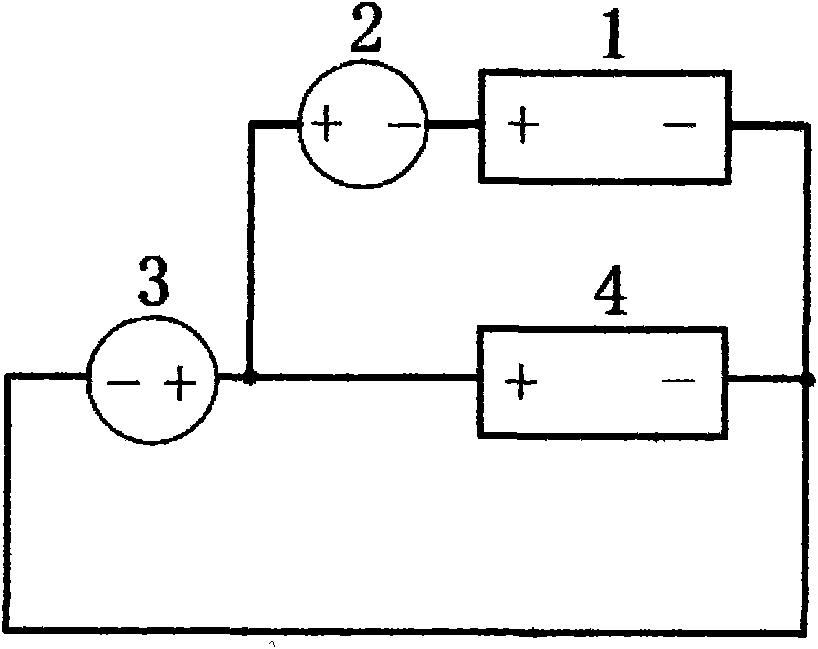

[0014] exist figure 1 Among them, the discharge battery pack (1) is connected in series with the supplementary pressure power supply (2) to charge the rechargeable battery pack (4). Simultaneously, the supplementary current power supply (3) also charges the rechargeable battery pack (4). The battery pack (4) can obtain the electric energy added by (3) and (1)(2). By adjusting the current of (2), the discharge current of (1) can be controlled according to the process design. Adjusting the current of (3) can control the charging current of (4). In order to meet the requirements of process design.

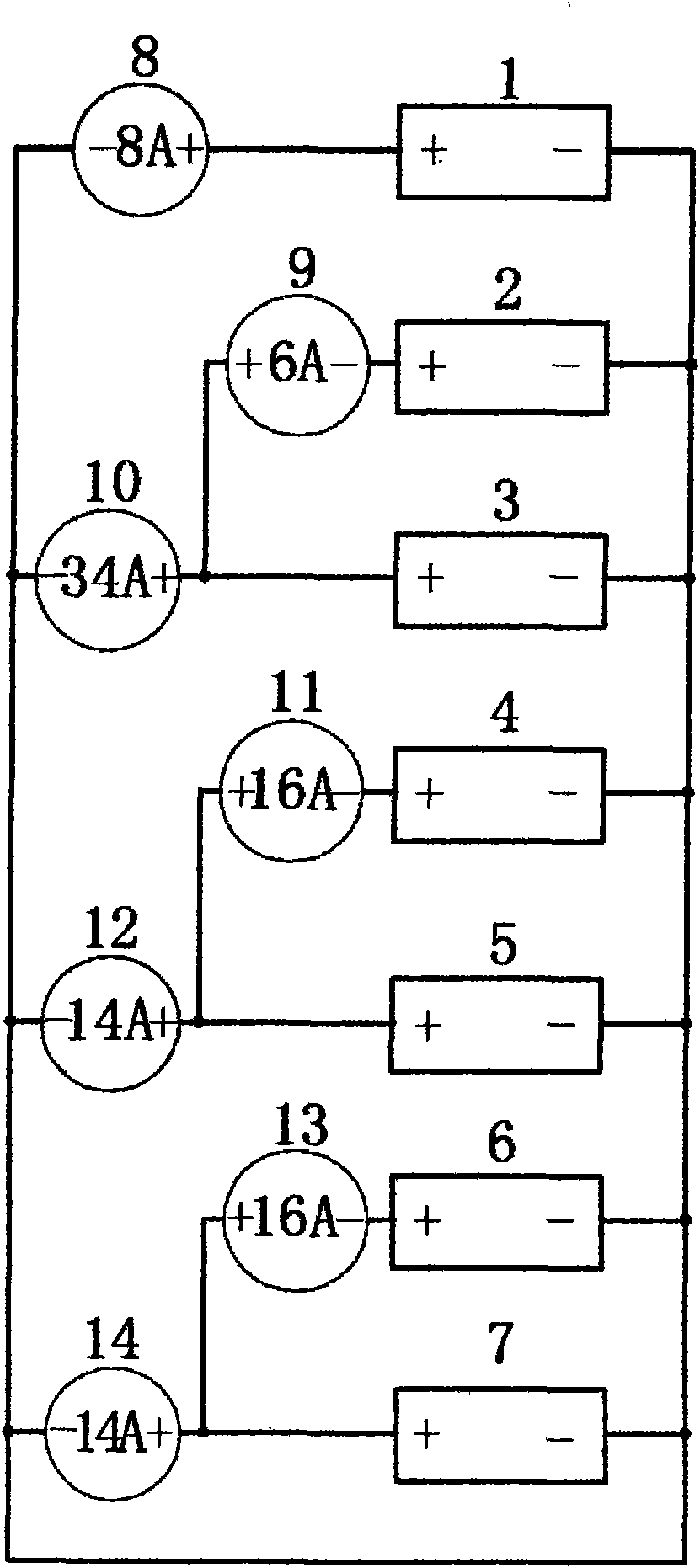

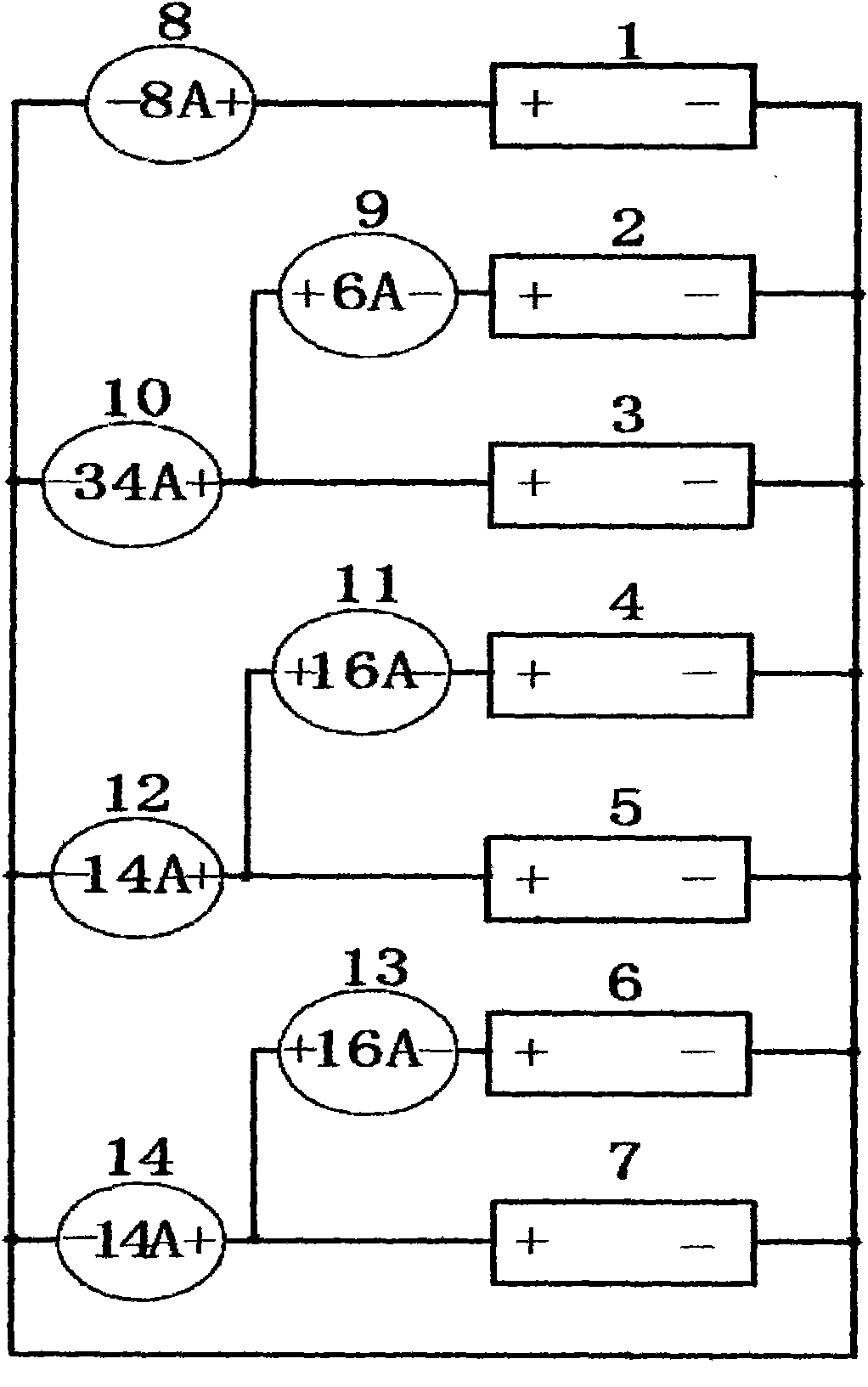

[0015] exist figure 2 In the 7-stage process embodiment shown, (2), (3), (9), and (10) are a group. (4), (5), (11), (12) are one group. (6), (7), (13), (14) are one group. form three groups of similar figure 1 The charging and discharging circuit of each power supply symbol is the charging and discharging current required by the process design.

[0016] After each stage of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com