Improved cold drawing mould of seamless steel pipe and cold drawing process thereof

A seamless steel pipe and mold technology, applied in the direction of wire drawing dies, etc., can solve the problems of the influence of enterprise production development, increase the number of drawing passes, and lengthen the production cycle, so as to shorten the production cycle, reduce the number of drawing passes, and improve the operation rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

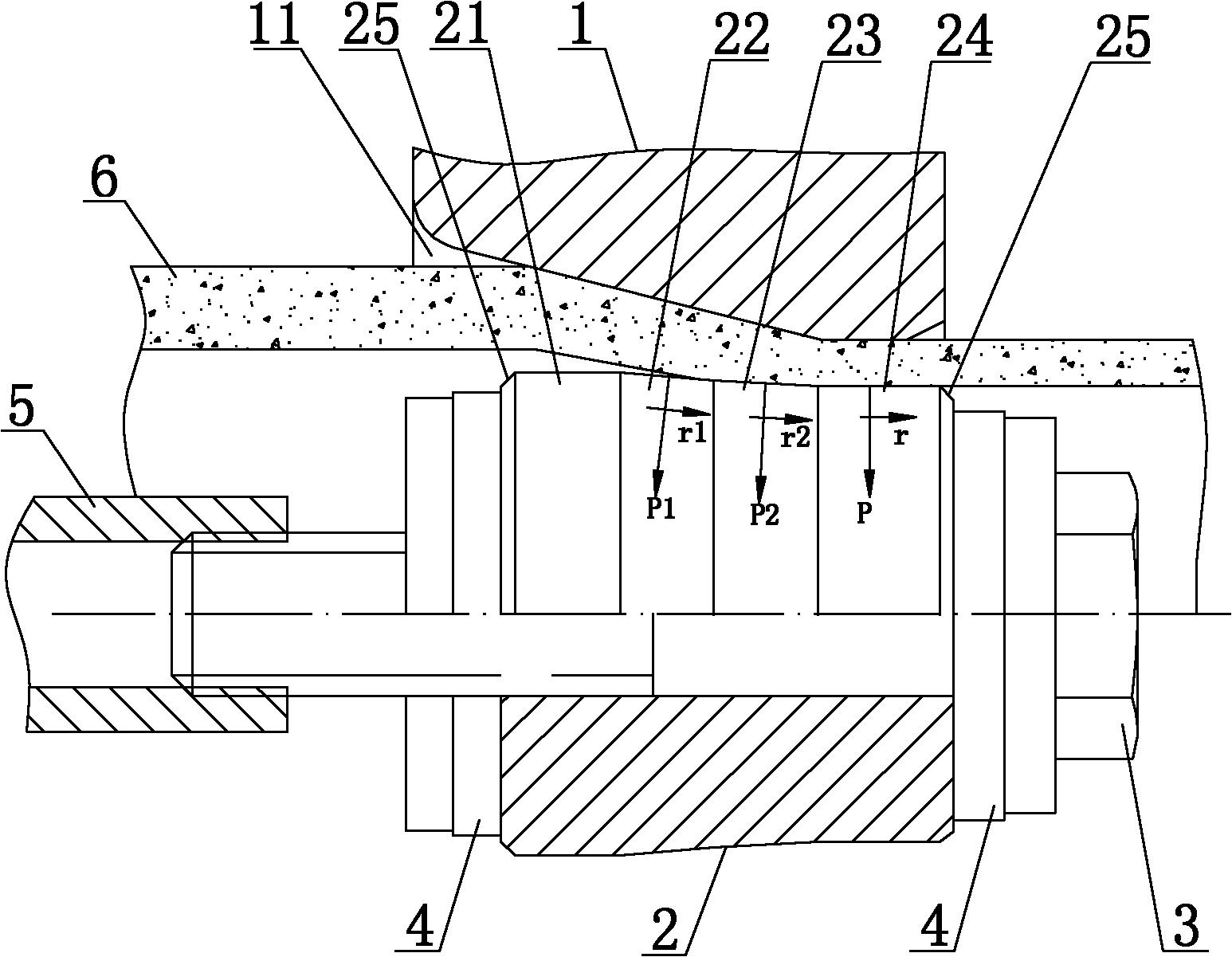

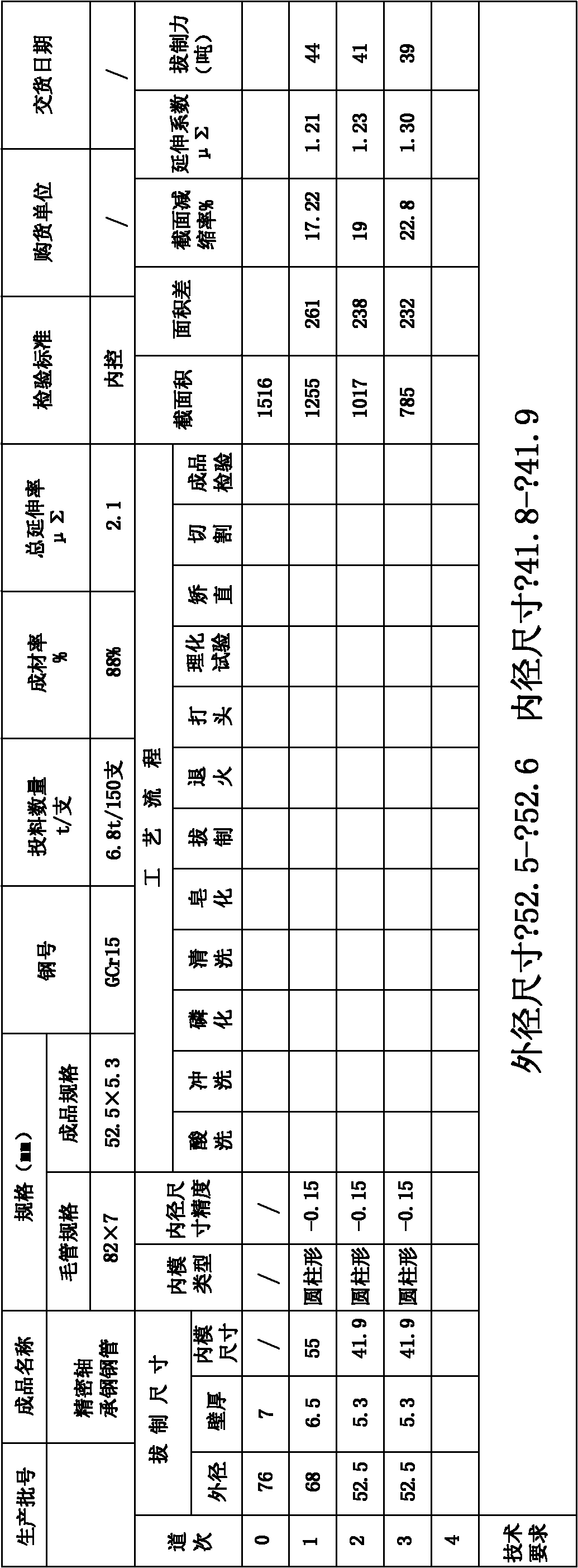

[0027] refer to figure 2 , the present invention is an improvement of a seamless steel pipe cold drawing die, comprising a cold drawing inner die 2 and a cold drawing outer die 1, a drawing die hole 11 is opened on the cold drawing outer die 1, and the cold drawing inner die 2 is formed along the steel pipe 6. The drawing direction is sequentially divided into a guide section 21, a conical wall-reducing section and a cylindrical uniform wall section 24. The conical wall-reducing section is divided into a first wall-reducing section 22 and a second wall-reducing section 23, the first wall-reducing section 22 is connected with the guide section 21, and the second wall-reducing section 23 is connected with the cylindrical uniform wall section 24; The axial taper of the wall reducing section 23 is smaller than the axial taper of the first wall reducing section 22 . In the drawing process, the wall reduction and diameter reduction of the steel pipe are divided into two steps, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com