Annular steel plate assembling and welding method and device

A ring-shaped steel plate and assembly method technology, applied in auxiliary devices, welding equipment, welding equipment and other directions, can solve the problems of low degree of mechanization, complex assembly and welding process, no effective solutions, etc., to achieve efficient automatic production, improve overall efficacy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

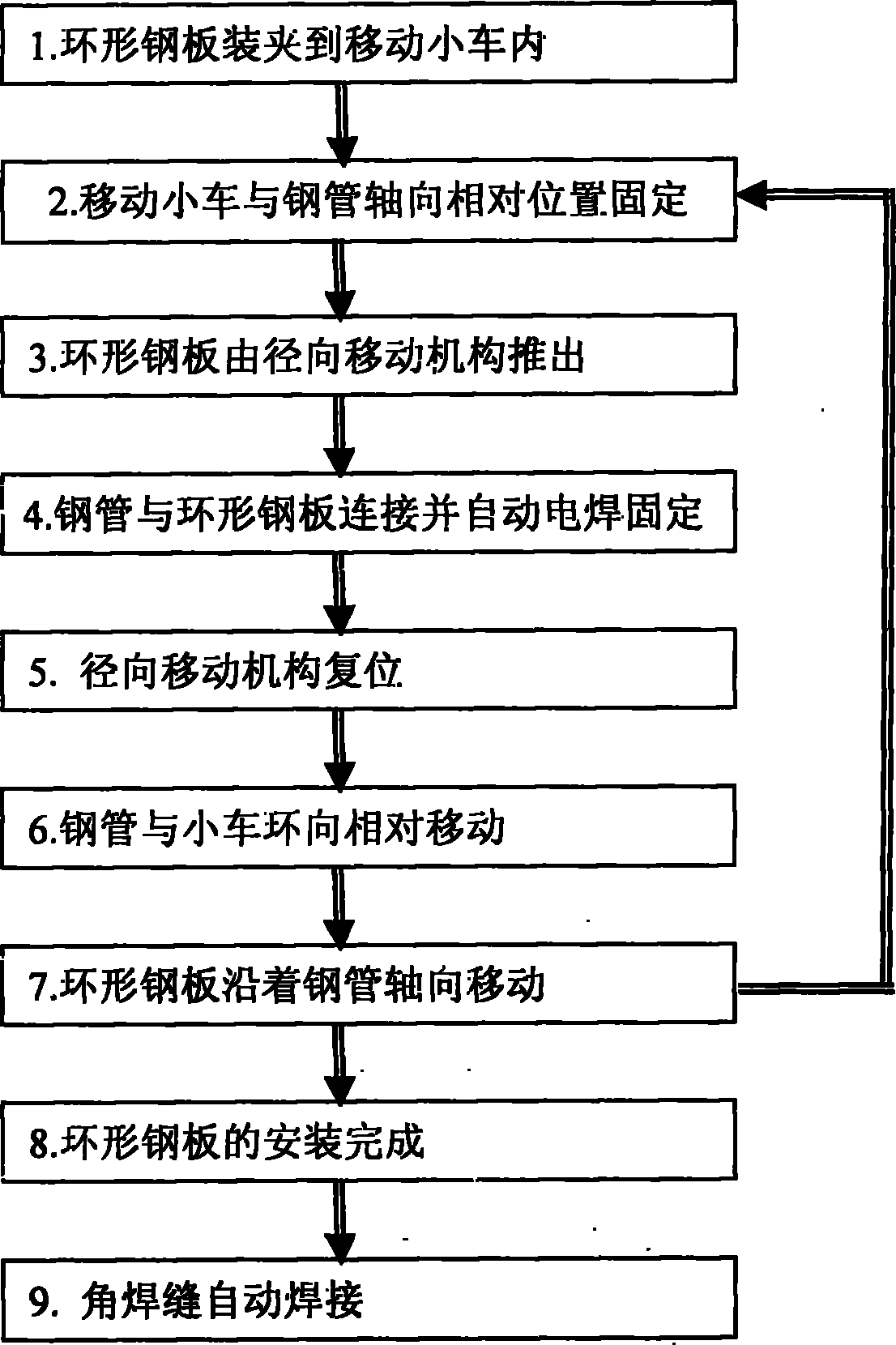

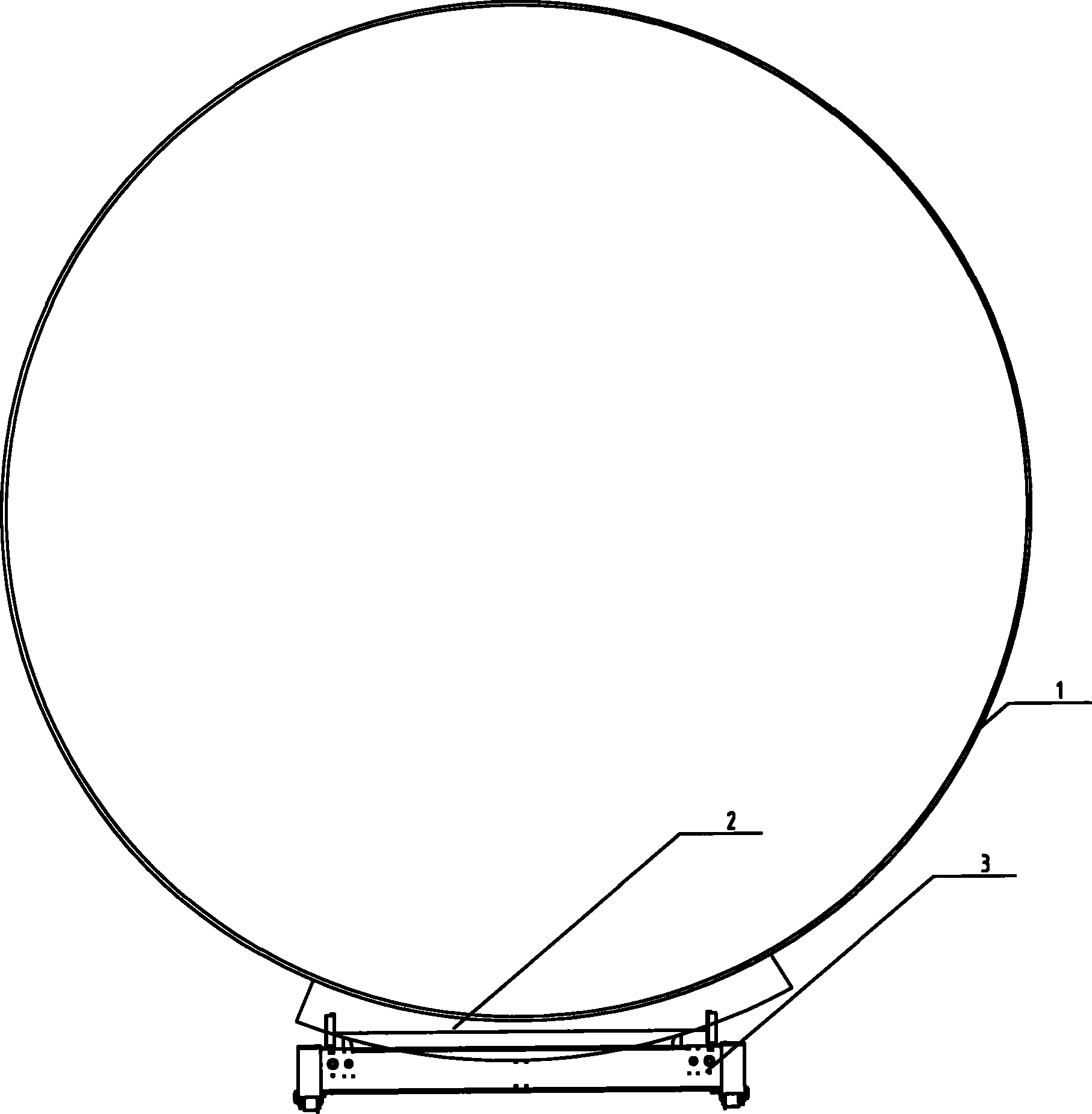

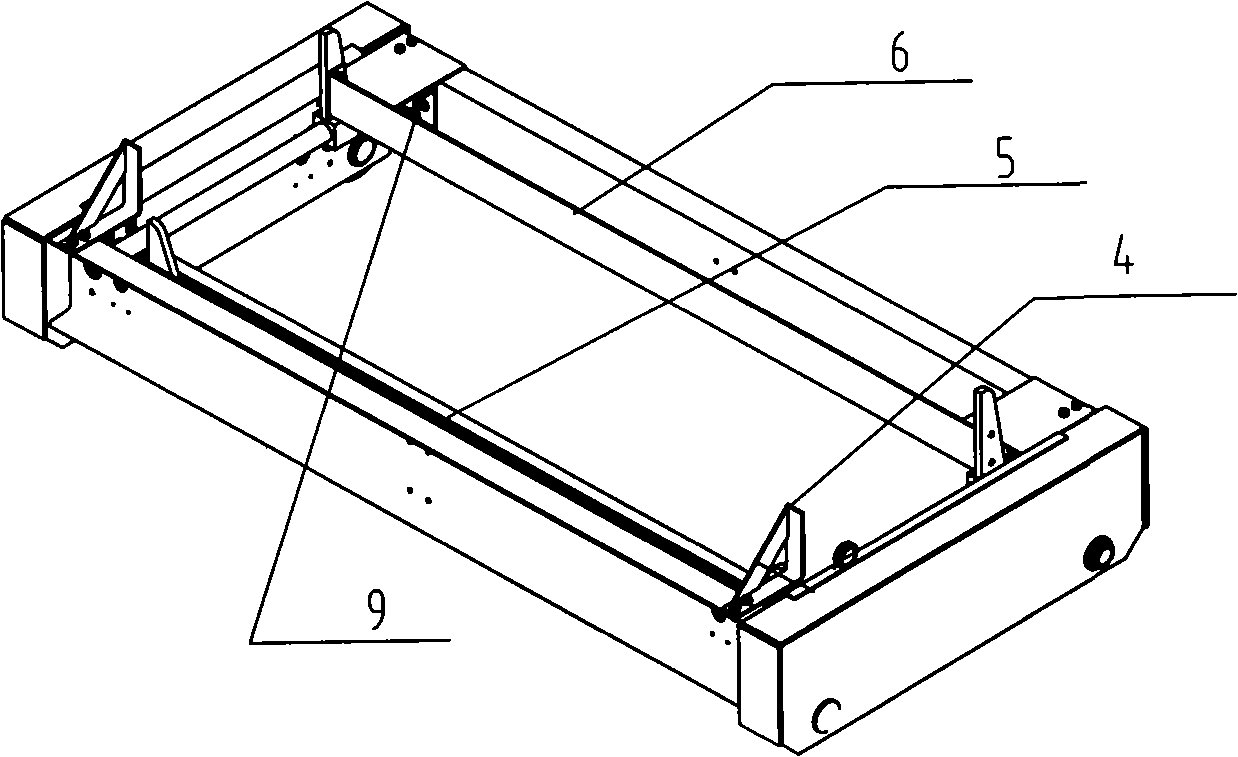

[0020] Embodiment 1: Carry out annular steel plate group welding at any place, as figure 2 , 3 , 4, and 5, the position of the steel pipe 1 is placed horizontally on the axis, and the ring-shaped steel plate 2 is transported to the bottom of the steel pipe with the rail trolley 3, and the steel pipe nozzle is used to limit the position where the trolley moves in the axial direction, so that a group of annular steel plates 2 are placed on the limit plate 4 The position of one end is just in the installation position of the structural design, start the radial movement mechanism 5, raise the annular steel plate 2 along the limit plate 4, and fit the steel pipe 1, fix the annular steel plate 2 by electric welding, and make the radial movement mechanism 5 times After arriving at the initial position, turn the steel pipe 1 for a section of the arc length of the annular steel plate 2, and start the axial movement mechanism 6 to move the remaining annular steel plate 2 as a whole for...

Embodiment 2

[0022] Embodiment 2: Carry out annular steel plate group welding in factory, as Figure 6 As shown, the steel pipe 1 is positioned vertically and fixedly on the axis, and the ring-shaped steel plate 2 is loaded by a trolley 3 that can be hung on the wall of the steel pipe 1, and transported to the upper part of the steel pipe 1 by a crane. , to limit the axial position of the trolley, the axial limit plate 4 defines the position of the upper end of the three sets of annular steel plates 2 just in the installation position of the structural design, start the radial movement mechanism 5, and move the annular steel plate along the position defined by the limit plate 4 Direction movement, fit with the steel pipe 1, fix the annular steel plate 2 by spot welding, make the radial movement mechanism 5 return to the initial position, then turn the trolley to pass a section of arc length of the annular steel plate 2, and start the hydraulic axial movement mechanism 6 to make the three T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com