Electromagnetic wedge-shaped bidirectional rope gripper

A rope gripper and wedge-shaped technology, applied in the field of electromagnetic wedge-shaped two-way rope grippers, can solve the problems of unable to stop the elevator and the rope gripper cannot be automatically reset, so as to avoid personal injury and property loss, save installation space and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

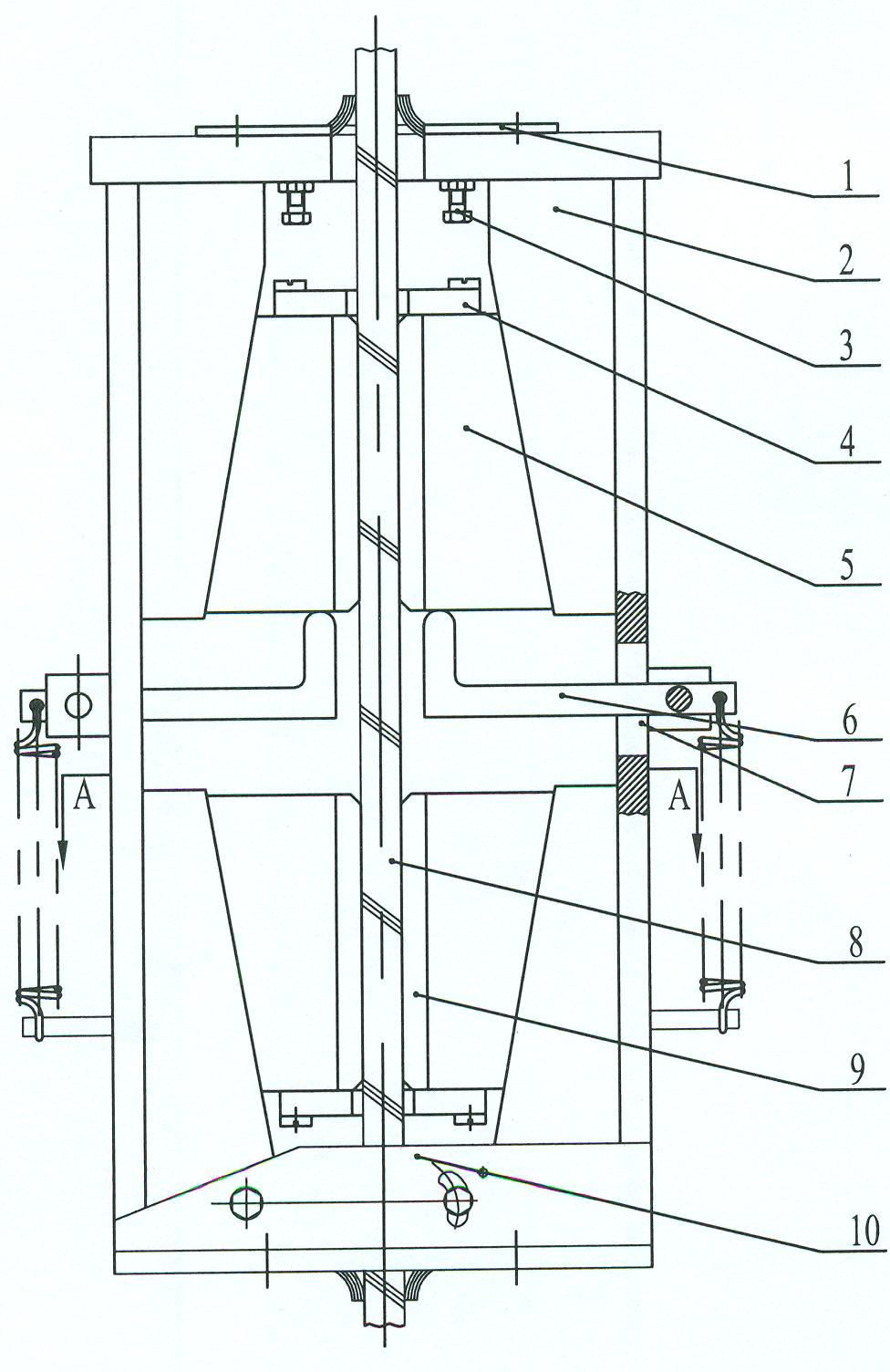

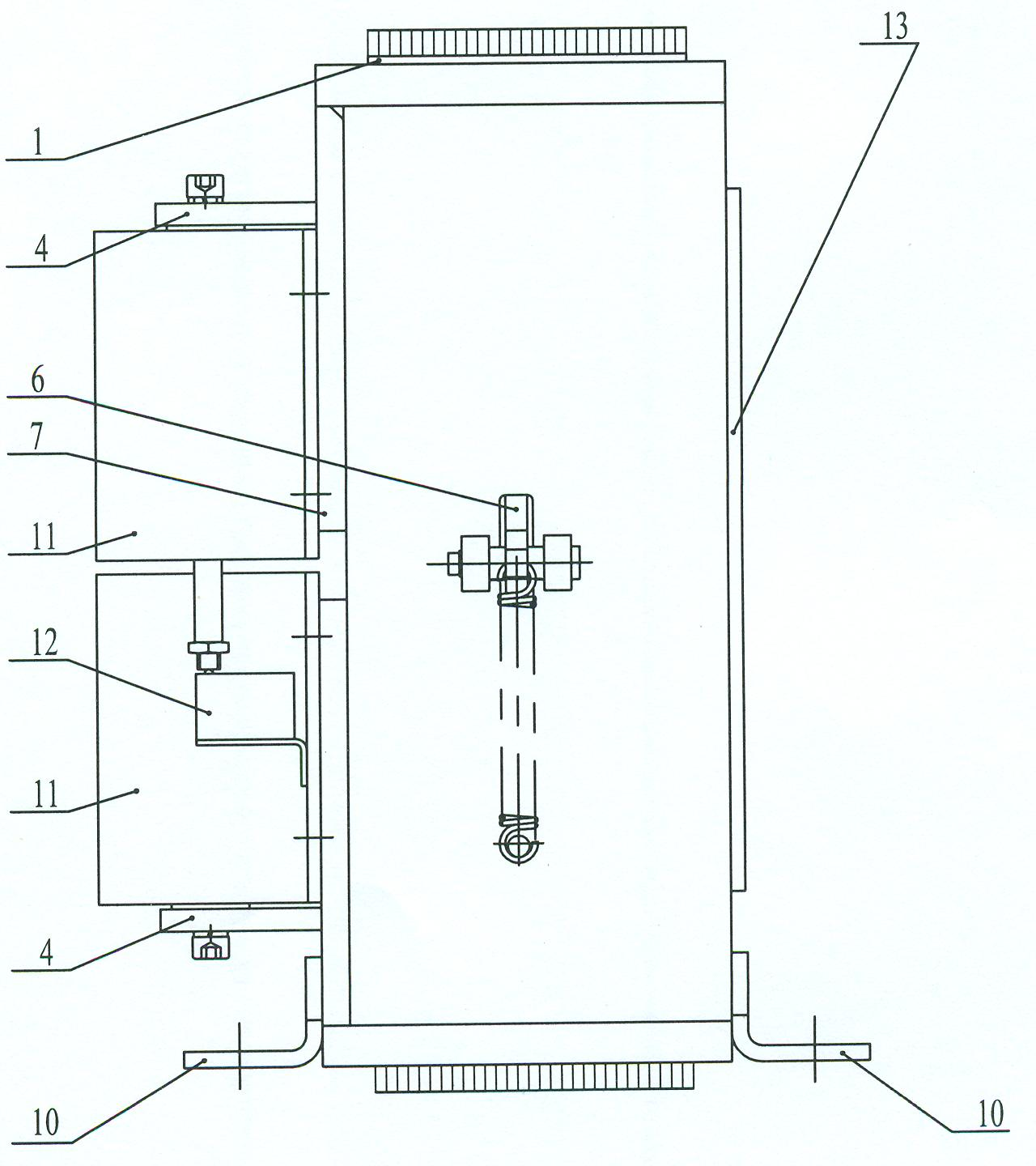

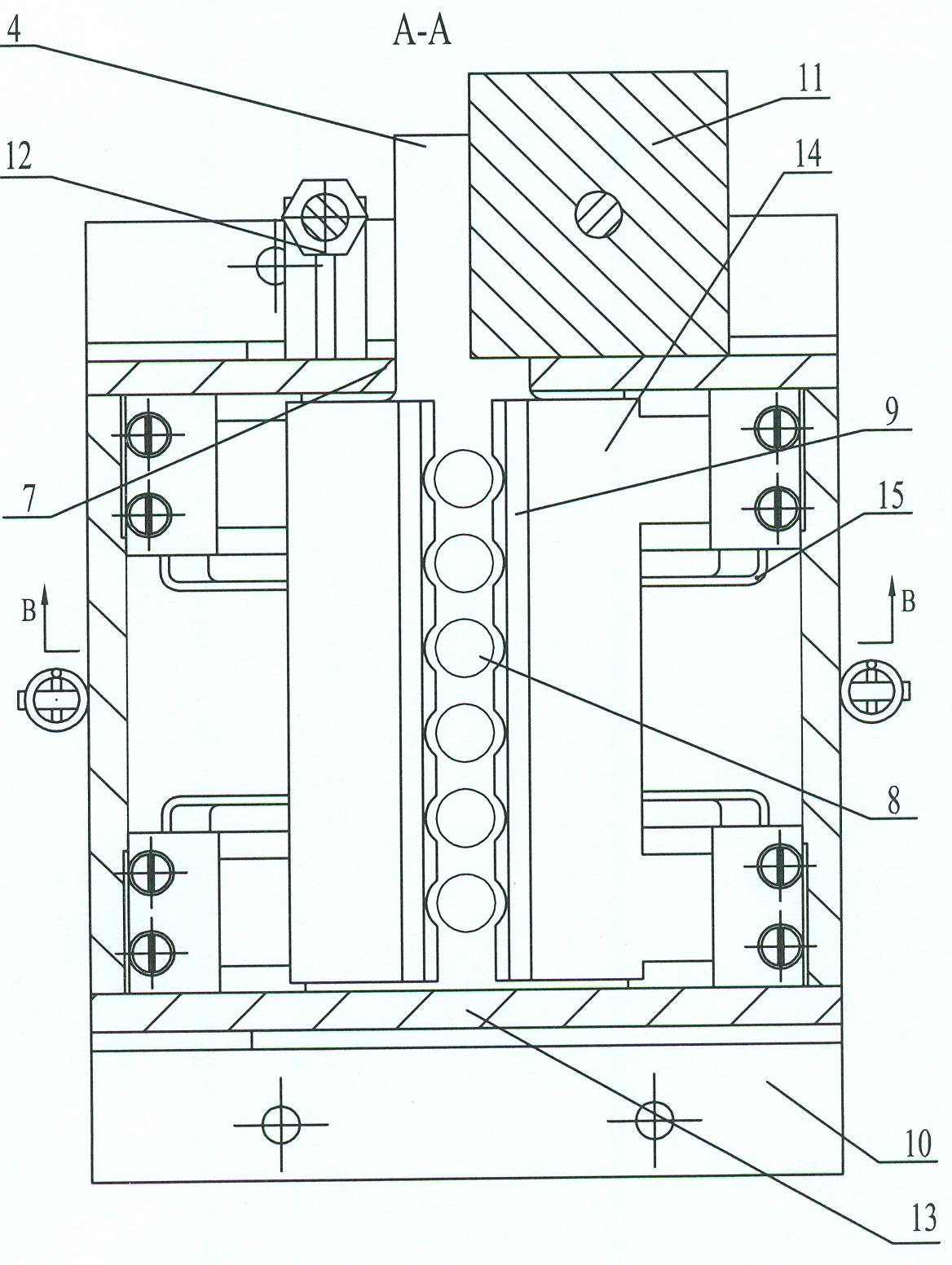

[0017] according to Figure 1~6 The specific structure of the present invention will be described in detail. The electromagnetic wedge-shaped two-way rope clamp includes a box body 7 with a base 10, a wedge-shaped guide body 2 assembled in the box body 7, and a groove formed by a brake pad 9 and a wedge that matches the outer circumference of the traction wire rope 8 of the traction machine. Block 14 constitutes the wedge assembly 5, wherein the specifications and shapes of the box body 7, the wedge guide 2 and the wedge assembly 5 should be selected according to actual needs. Two wedge assemblies 5 located on the outer periphery of the traction wire rope 8 are movably assembled on the slideway of the wedge-shaped guide body 2 by using the sliding guide frame 15 respectively. The limit pins at the ends of the two wedge assemblies 5 are respectively assembled in the waist-shaped holes of the same linkage support base 4, and the limit pins can move along the waist-shaped holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com