Automatic milk powder-reconstituting device

A technology for brewer and milk powder, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of difficult to guarantee hygiene and safety, easy to cause negligence, scalding accidents for infants and young children, etc. The effect of nutrition, timely and safe feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

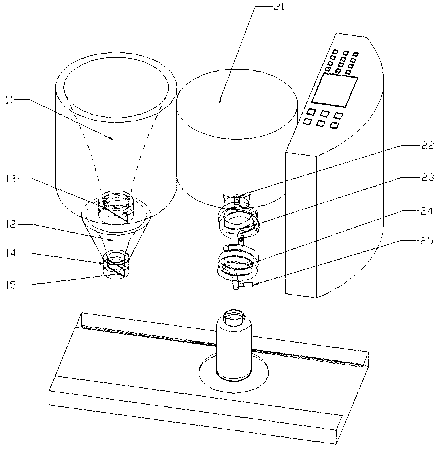

[0018] like figure 1 As shown, in this embodiment, the present invention includes a milk powder supply device, a water supply device, and a circuit control device. The milk powder supply device includes a storage 11, and the storage 11 is used to store milk powder. The user can put the whole can or the whole bag of milk powder After opening the package, pour it into the storage 11 for standby; the lower part of the storage 11 is provided with a temporary storage bin 12, and the temporary storage bin 12 is used for temporarily storing the milk powder for preparation during the milk powder brewing process; An electronic valve I13 is arranged between the temporary storage bin 12 and the storage container 11, and a weighing device 14 is provided at the bottom of the temporary storage bin 12, and the weighing device 14 is used to obtain the amount of milk powder in the temporary storage bin 12. The weight data is fed back to the circuit control device. An electronic valve II15 is p...

Embodiment 2

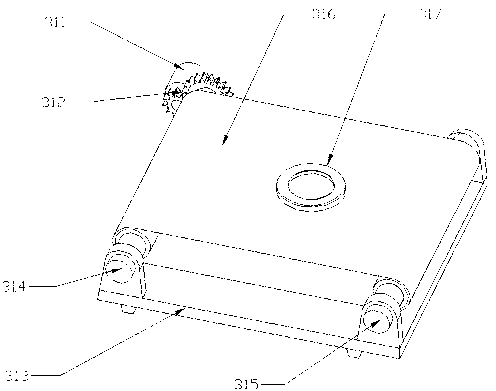

[0024] like figure 1 , Figure 2a As shown, compared with Embodiment 1, the difference of this embodiment is: In this embodiment, the automatic milk powder brewer also includes a displacement device, and the displacement device is located below the supply device and the water supply device corresponding to The scheme adopted by the displacement device in this embodiment is: the displacement device includes a transmission motor 311, a gear transmission 312, a base 313, a transmission shaft 314, a driven shaft 315, and the transmission shaft 314 and the driven shaft 315 is provided with both ends of the base 313 through bearings, the transmission motor 311 is connected to the transmission shaft 314 through the gear transmission device 312, and the transmission shaft 314 and the driven shaft 315 are equipped with a transmission belt 316 , the transmission belt 316 is provided with a milk cup placement platform 317, and the transmission motor 311 is electrically connected to the ...

Embodiment example 3

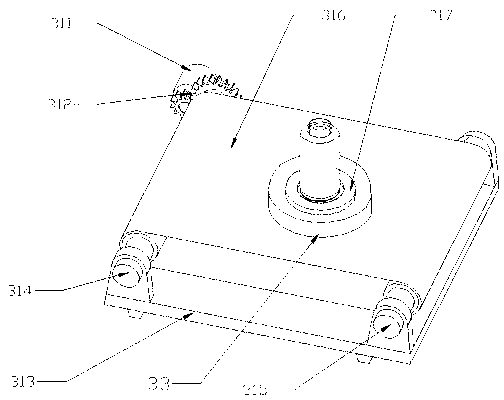

[0030] like figure 1 , Figure 3a As shown, in this embodiment, the scheme adopted by the displacement device is: the displacement device includes a stepping motor 321, a frame 322, a transmission screw 323, and a moving platform 324, and the two ends of the transmission screw 323 are connected to the The frame 322 is rotatably fitted, the stepping motor 321 is arranged at one end of the frame 322 and is connected to the transmission screw 323 in transmission, the moving platform 324 is in transmission cooperation with the transmission screw 323, and the moving platform The side of 323 is provided with protrusions to match the guide grooves provided on the frame 322, the mobile platform 323 is provided with a milk cup fixing groove 325, and the stepping motor 321 is electrically connected to the circuit control device. like Figure 3b As shown, as an optimization, an oscillating motor 33 is provided at the bottom of the milk cup fixing groove 325, the oscillating motor 33 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com