Partitioned diesel engine water tank filter

A diesel engine, split technology, applied in the direction of fixed filter elements, filter separation, separation methods, etc., can solve the problems of incomplete use, reduce the service life and damage of buoys, sliders and water floats, and achieve complete use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

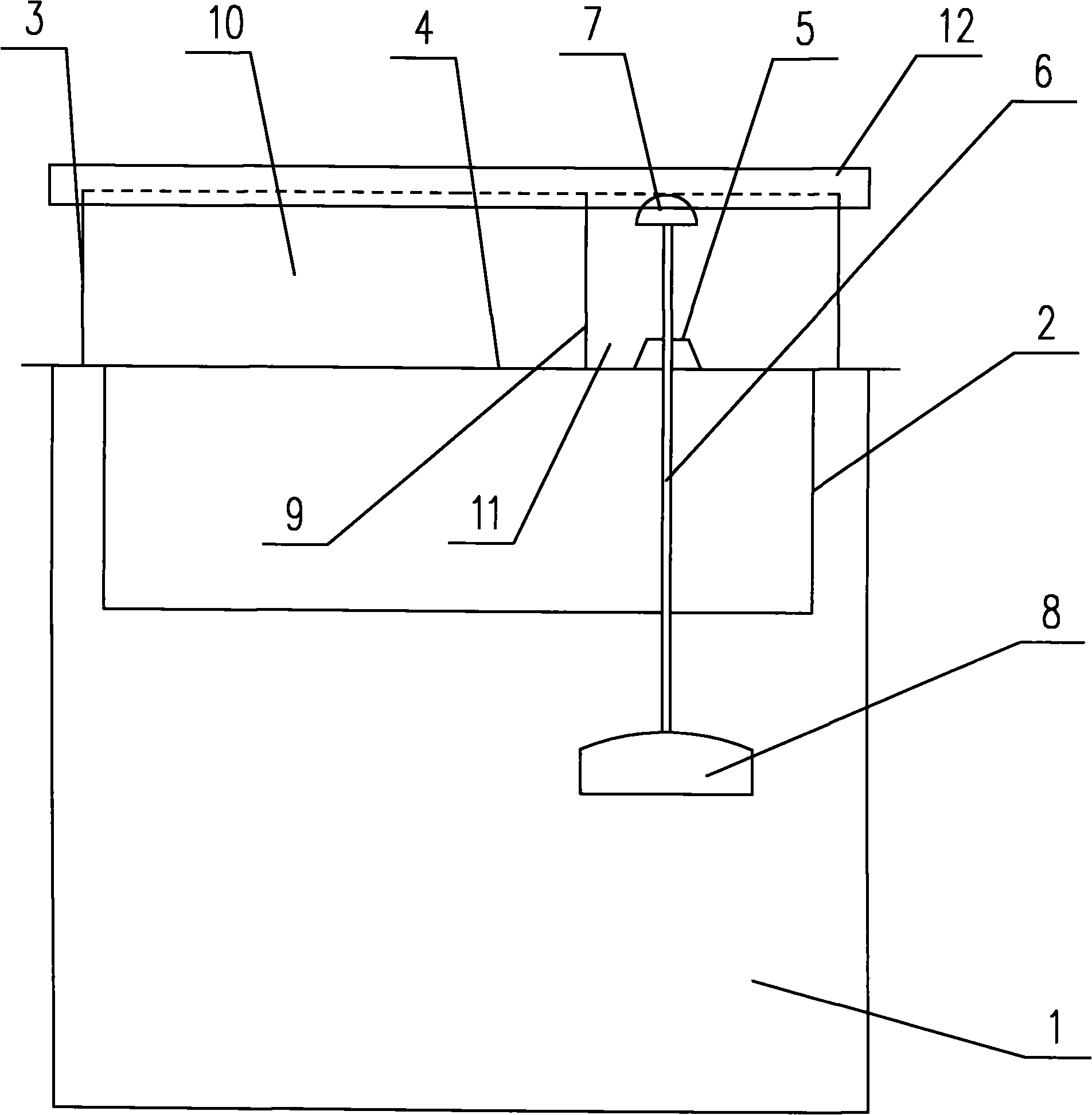

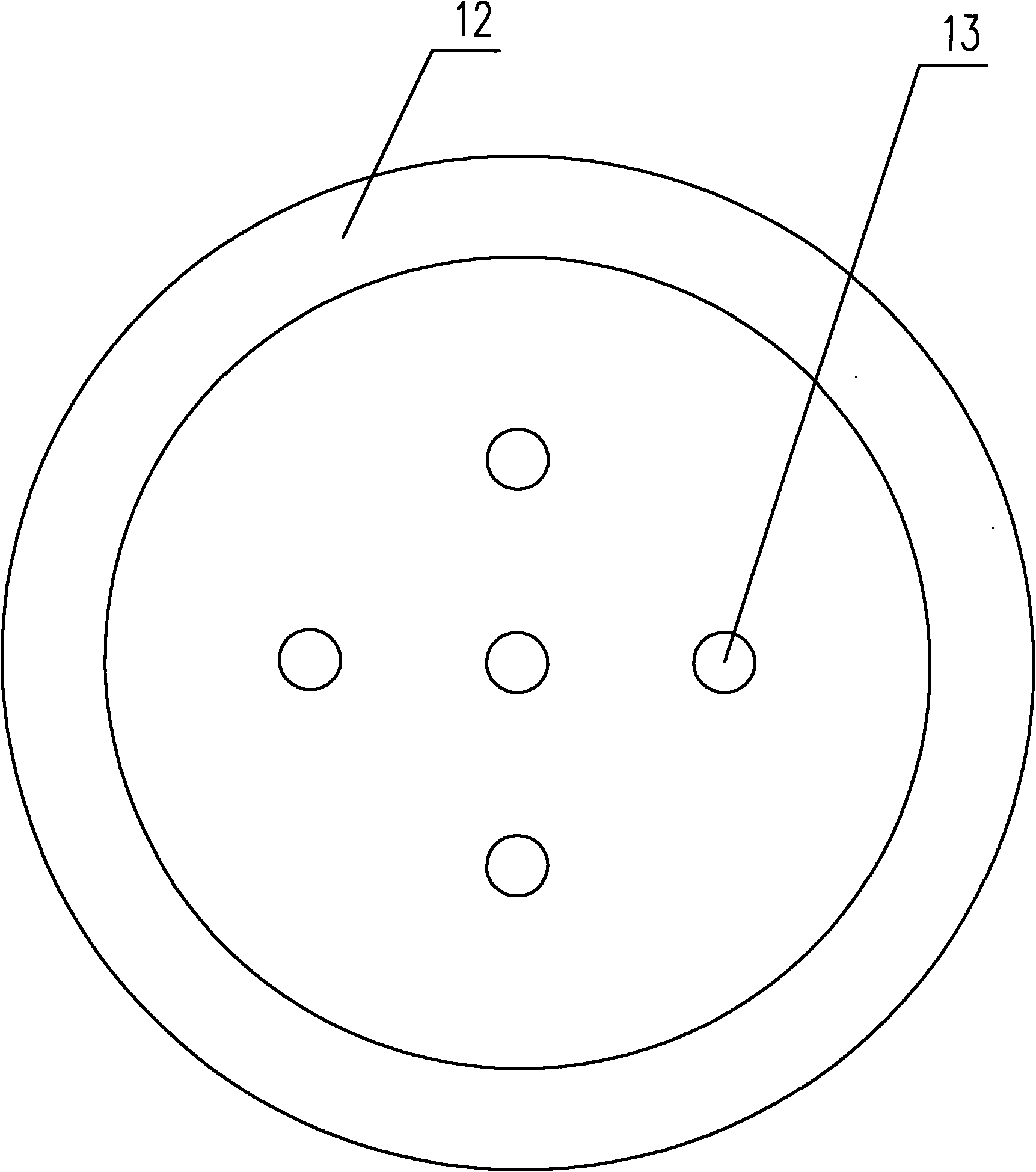

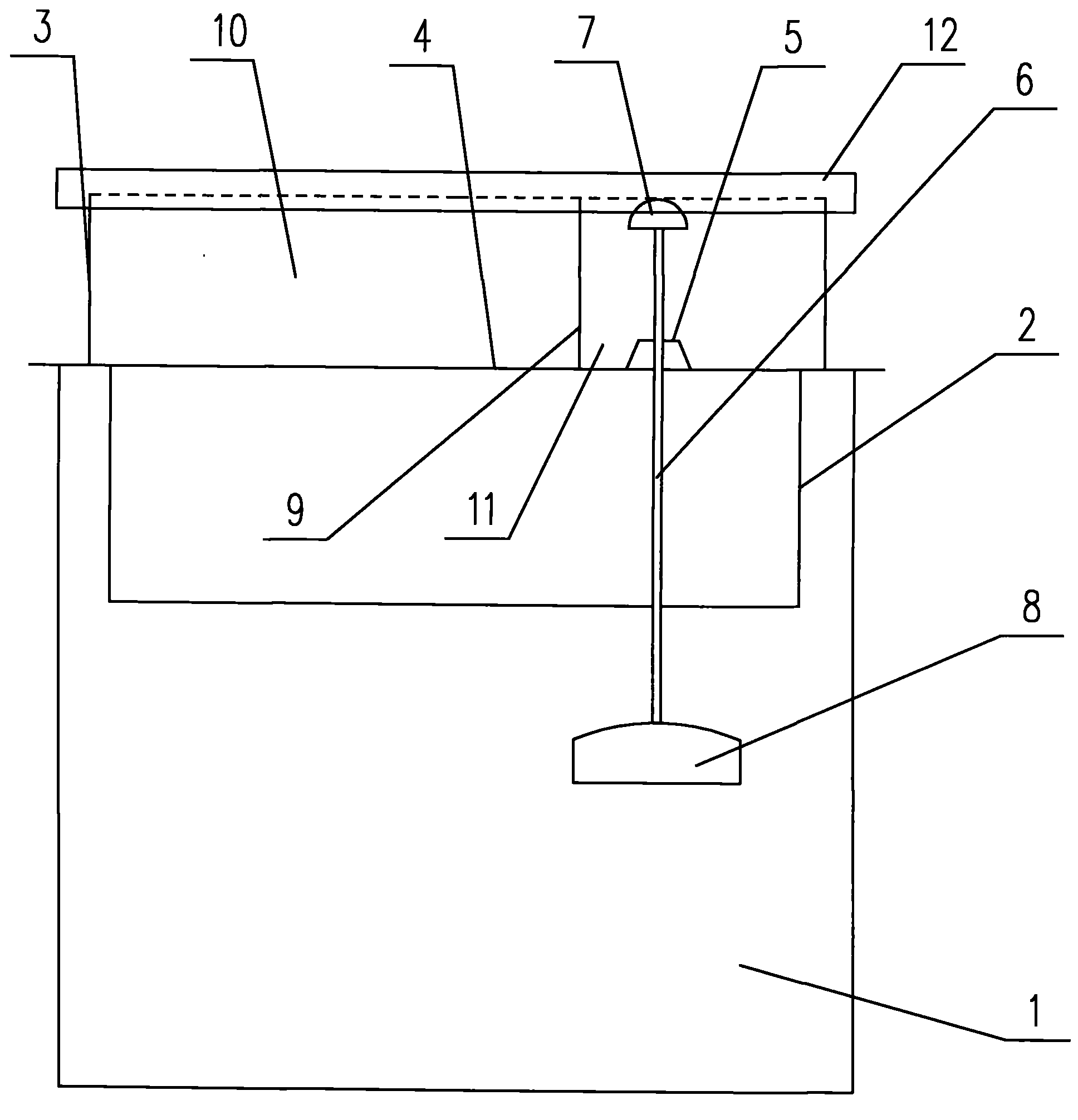

[0010] Such as figure 1 , figure 2 As shown, the split type diesel engine water tank filter includes: a filter seat 2 arranged on the water tank 1, a water filling port 3 arranged on the filter seat 2, and a filter screen is arranged between the water filling port 3 and the filter seat 2 4. A guide seat 5 is provided on the filter screen 4, a slide bar 6 is movable in the guide seat 5, a buoy 7 is fixedly installed at the upper end of the slide bar 6, and a water tank is fixedly installed at the lower end of the slide bar 6 in the water tank 1. The float 8 is fixedly provided with a dividing plate 9 on the filter screen 4, and the dividing plate 9 divides the water filling port 3 into two parts, the water filling chamber 10 and the buoy chamber 11, and the water filling chamber 10 has a larger area than the buoy chamber 11. The guide seat 5, the slide bar 6, the buoy 7 and the water float 8 are all arranged in the buoy cavity 11, and a cover 12 is arranged on the described w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com