Melted magnesium supply pump and control method for the same

A technology for supplying pumps and magnesium melting, which is applied to equipment for supplying molten metal, pump control, control of pouring molten metal from ladles, etc., which can solve the problems of high cost and low maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, the present invention will be described based on preferred embodiments with reference to the drawings. The same reference numerals are assigned to the same or equivalent structural elements, members, and processes shown in the drawings, and overlapping descriptions are appropriately omitted. In addition, the embodiment does not limit the invention but is only an example, and all the features described in the embodiment or a combination thereof are not necessarily essential technical features of the invention.

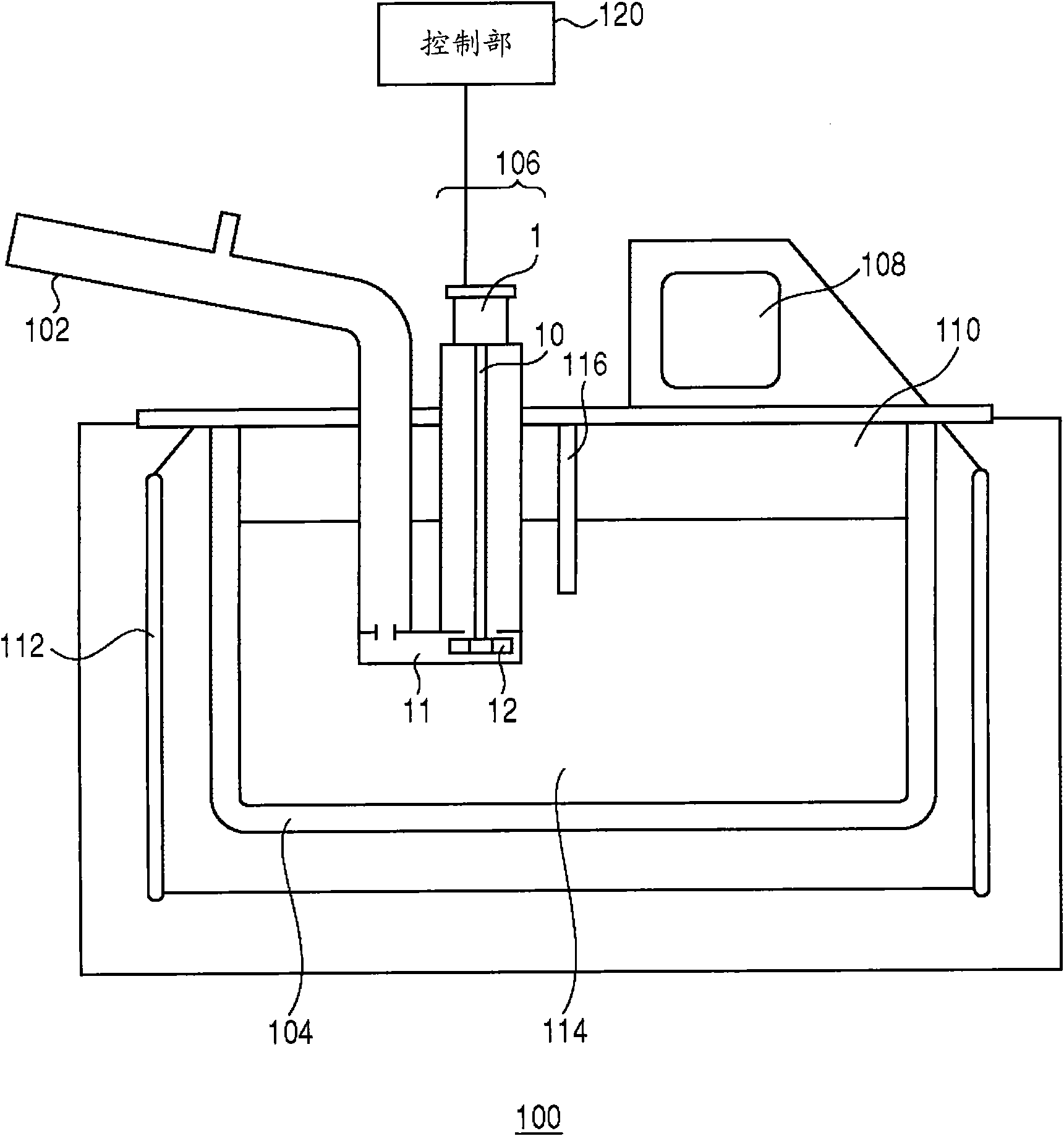

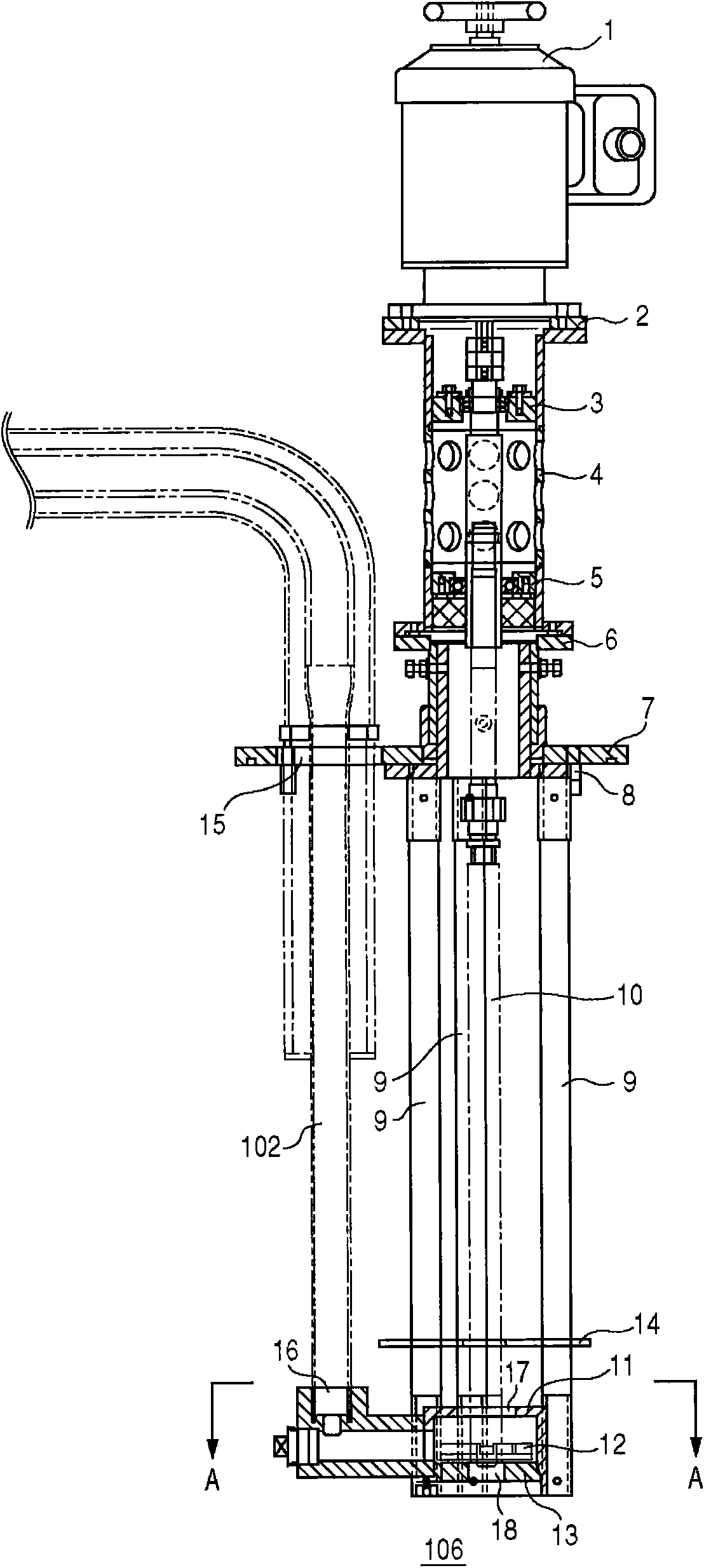

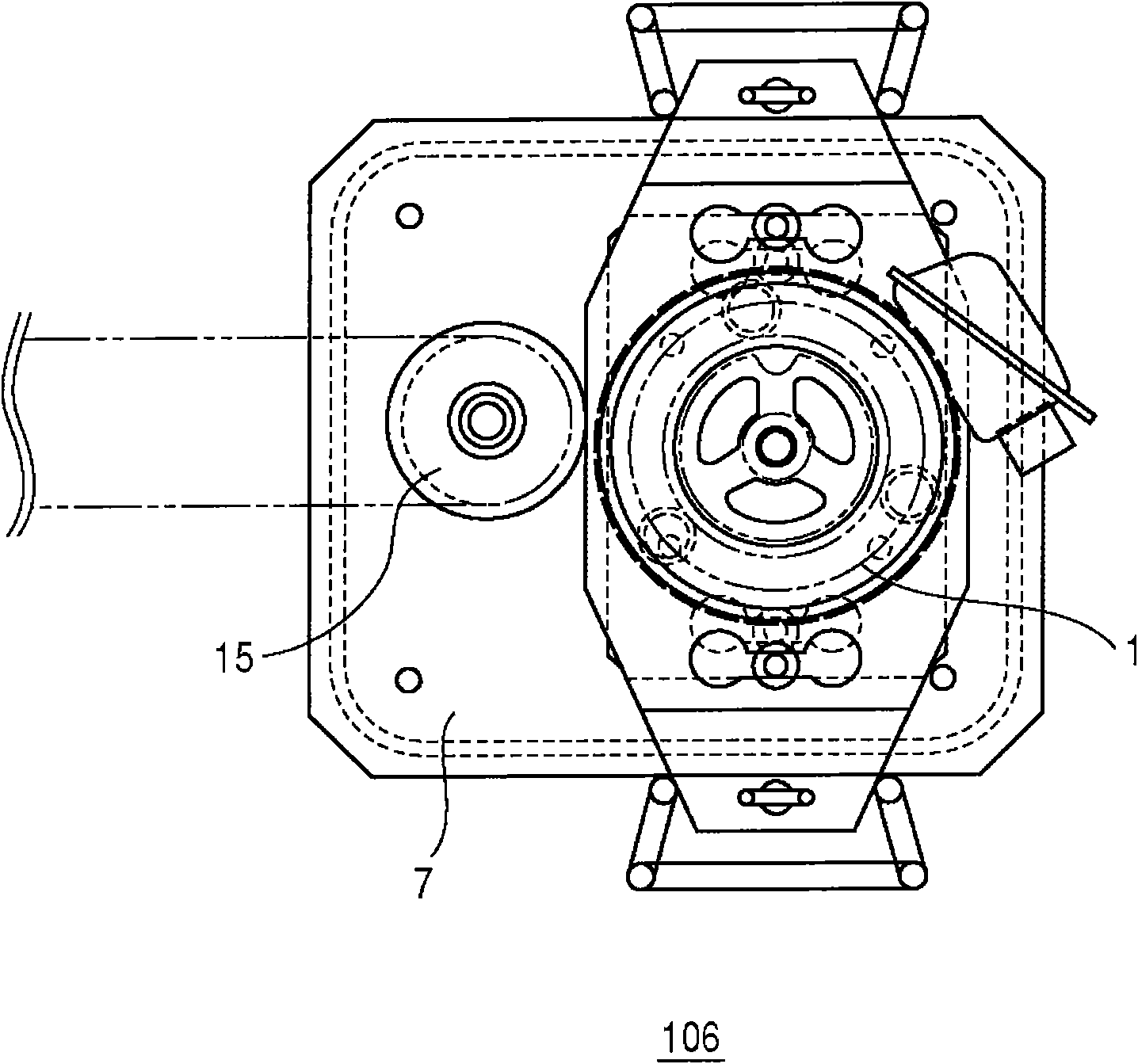

[0026] figure 1 It is a figure which shows the structure of the magnesium melt supply apparatus of embodiment. The magnesium melt supply device 100 mainly includes a melt conduit 102 , a container (crucible) 104 , a melt supply pump 106 , and a control unit 120 . Magnesium ingots, reflow materials, etc. (hereinafter referred to as ingots or materials) heated by an unillustrated ingot preheating device are appropriately charged into the ingot chargi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com