Printing press with cylinder adjustment and control devices

A technology for converting devices and printing machines, which is applied to rotary printing machines, printing machines, printing, etc., and can solve problems such as the inability to keep the pressure of rolling pillows constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

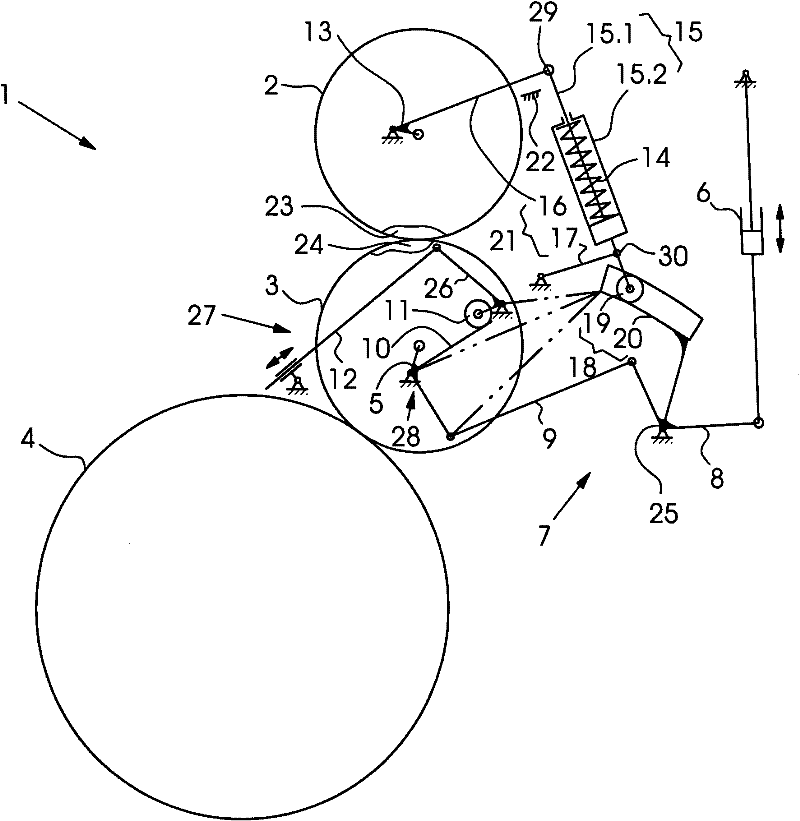

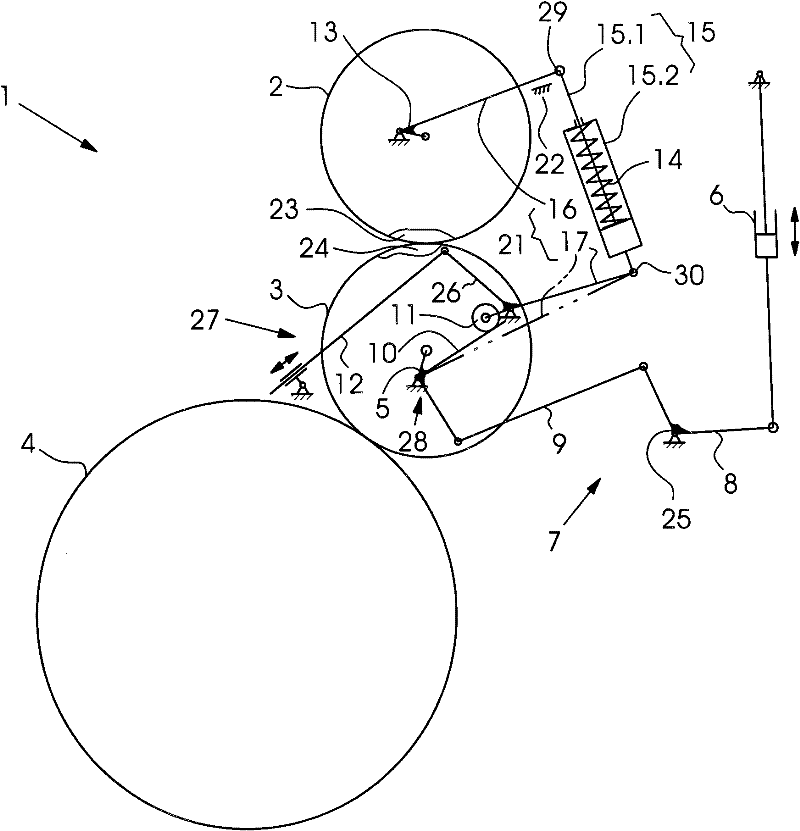

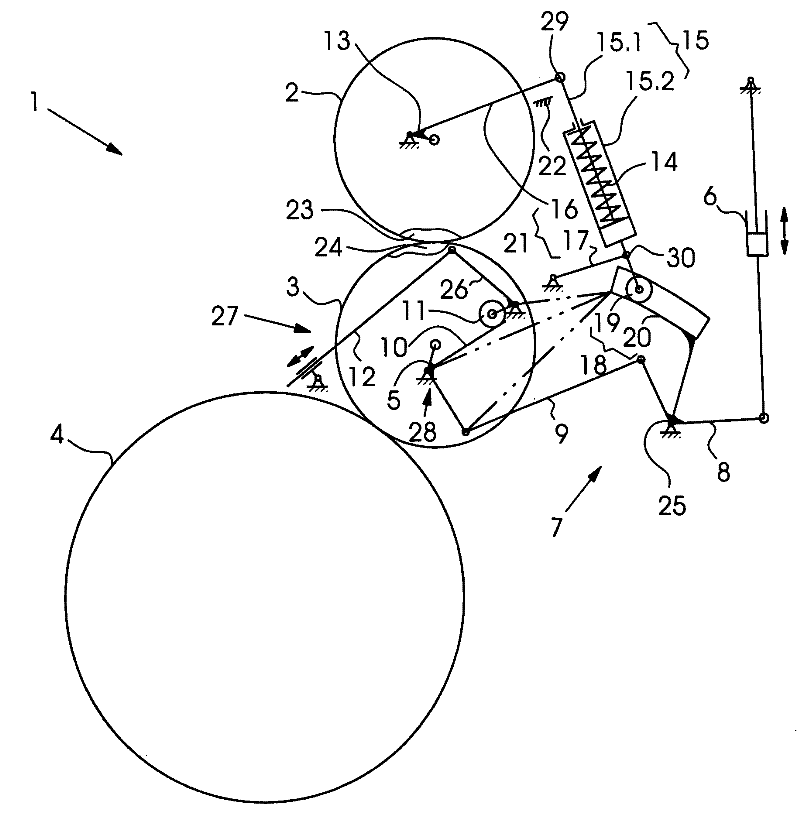

[0015] exist figure 1 with 2 In , members and elements corresponding to each other are provided with the same reference numerals.

[0016] exist figure 1 A printing press 1 for lithographic offset printing on printing sheets is shown in FIG. The printing press 1 comprises a plate cylinder 2 , a blanket cylinder 3 and an impression cylinder 4 . The blanket cylinder 3 is mounted in a first eccentric bearing 5 , by adjusting the eccentric bearing, the blanket cylinder 3 can optionally be adjusted into an initial printing position and an end printing position. The first eccentric bearing 5 is an integral part of a switching device 28 for switching the blanket cylinder 3 relative to the impression cylinder 4 at the start of printing and at the end of printing. The adjustment of the eccentric bearing 5 is driven by a pneumatic cylinder 6 via a four-joint transmission 7 .

[0017] The four-hinge transmission device 7 includes a double-arm driving rocker 8 , a connecting rod 9 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com