Screen-printing fixture of dispersion prism

A spectroscopic prism and screen printing technology, applied in screen printing machines, printing, printing machines, etc., can solve the problems of low processing efficiency, high labor intensity, inaccurate positioning, etc., to improve processing efficiency, reduce labor intensity, and ensure silk screen printing. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

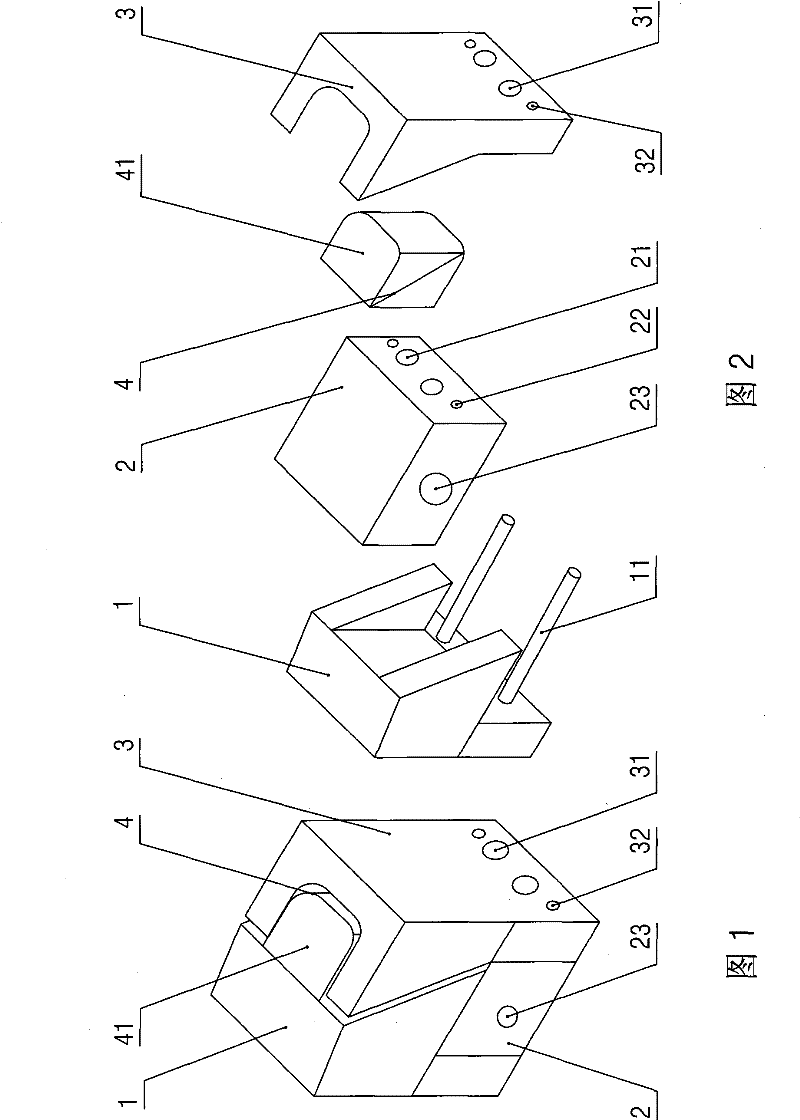

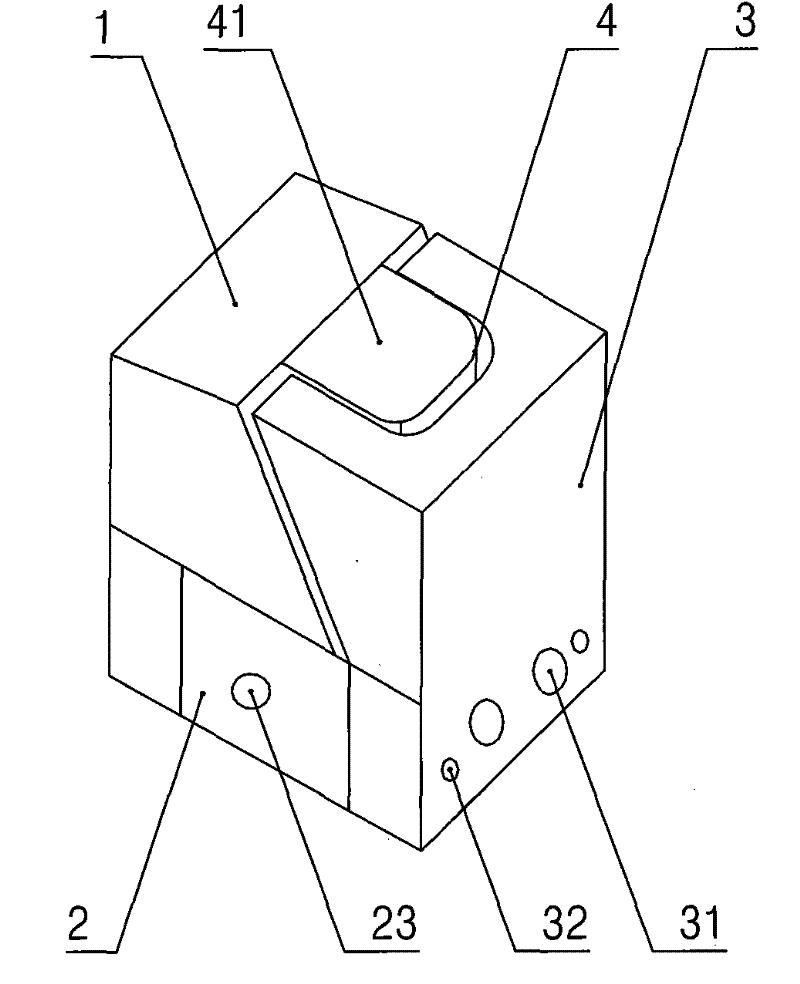

[0010] like figure 2 As shown, the silk screen fixture of the dichroic prism of the present invention includes: a left support 1, a right support 3 and a slider 2, and the upper parts of the left and right support 1 and 3 are respectively provided with a Draw-in slots, after the pair of draw-in slots are combined, the beam splitting prism 4 is just clamped in the middle, the bottom of the left support 1 is provided with a pair of guide rods 11 parallel to each other, and the right support 3 and the slider 2 are respectively provided with a pair of The guide holes 31 and 21 matched with the guide rod 11, the right support 3 is provided with a fixing hole 32, the right end surface of the slider 2 is provided with a fixing threaded hole 22 matched with the fixing hole 32, one side of the slider 2 A fastening threaded hole 23 communicated with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com