Combined railway frog

A combined, railway technology, applied in the direction of roads, switches, tracks, etc., can solve the problems of poor impact resistance, difficult welding, and manufacturing difficulties at the weld, achieve strong integrity, improve impact resistance, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

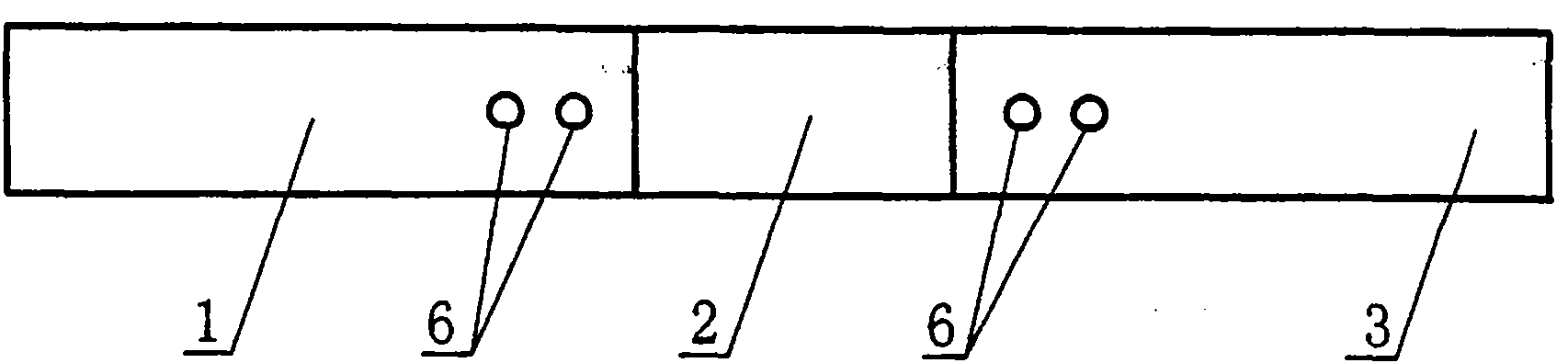

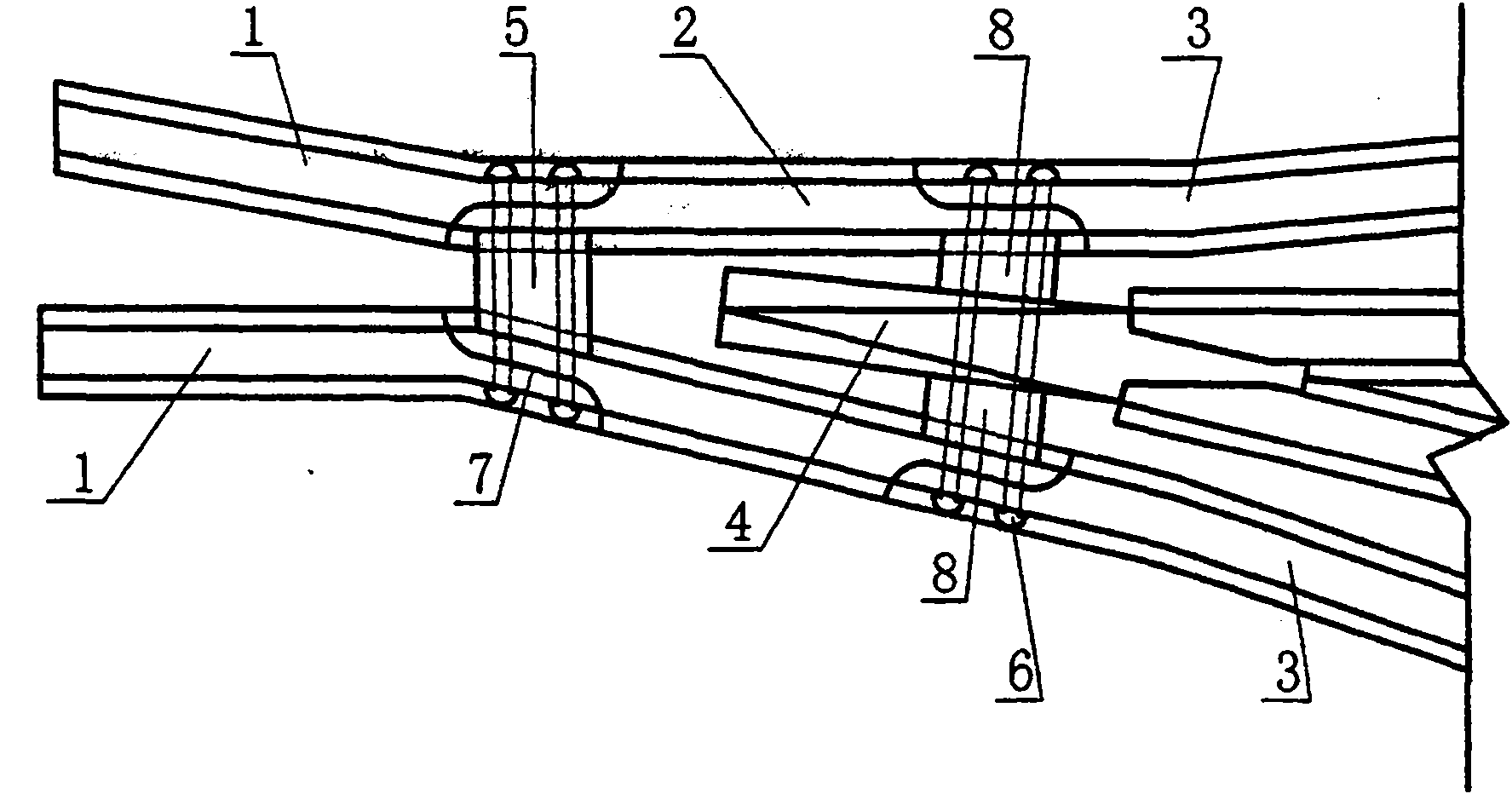

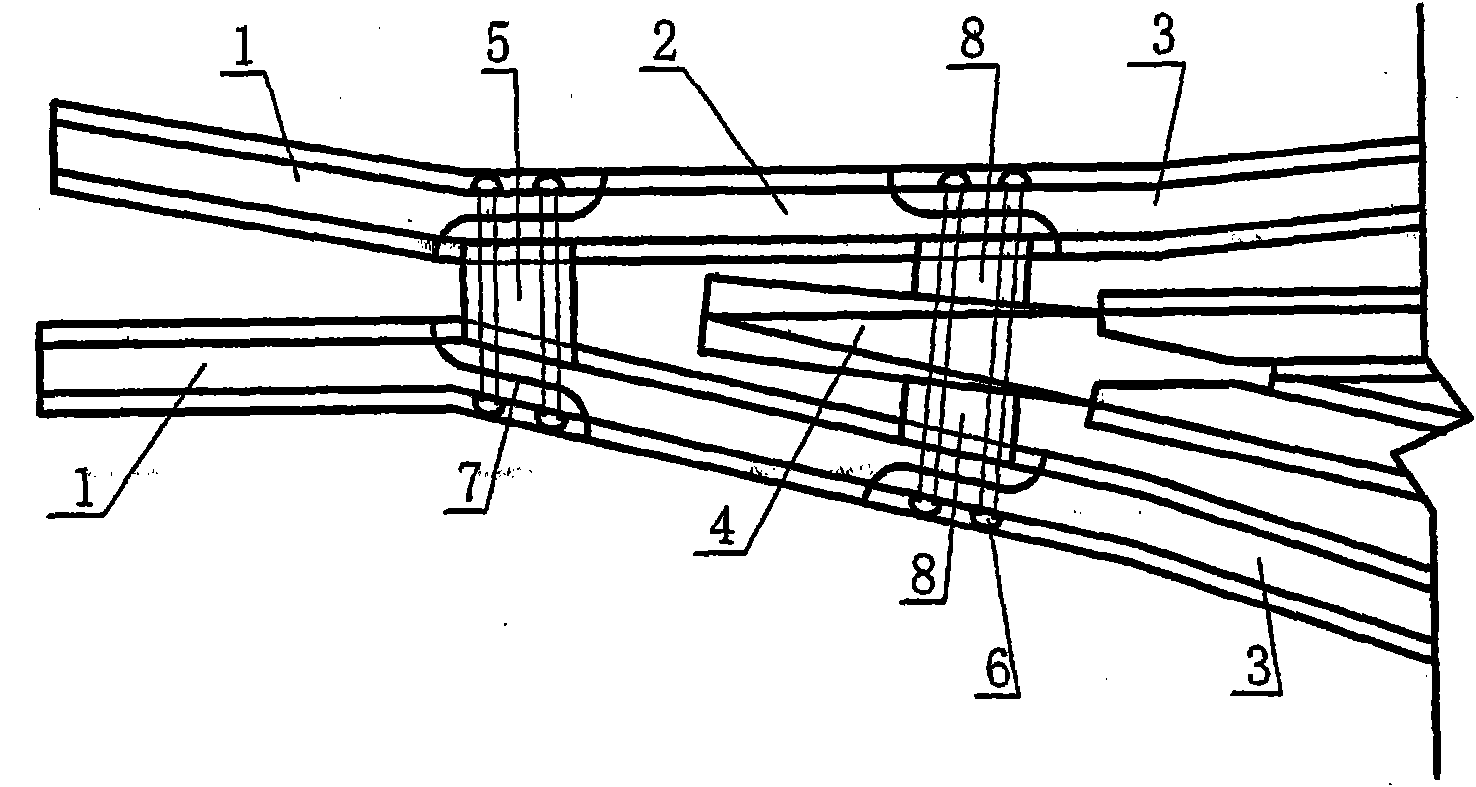

[0010] see Figure 1~2 , the combined railway frog includes a fork center 4, which is arranged on both sides of the fork center 4 and consists of a front ordinary rail section 1, a rear ordinary rail section 3, and an alloy steel reinforcement section 2 arranged between the front and rear ordinary rail sections. The wing rail is characterized in that the alloy steel reinforced section and the ordinary steel rail section are transitionally connected by a limit fit line 7, and a spacer iron 5 is arranged at the joint of the limit fit line between the two wing rails, and the wing rail and the Spacer irons 8 are arranged at the joints of the limit fit lines between the fork centers, and the bolts 6 passing through the spacer irons are connected between the two wing rails and between the wing rails and the fork centers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com