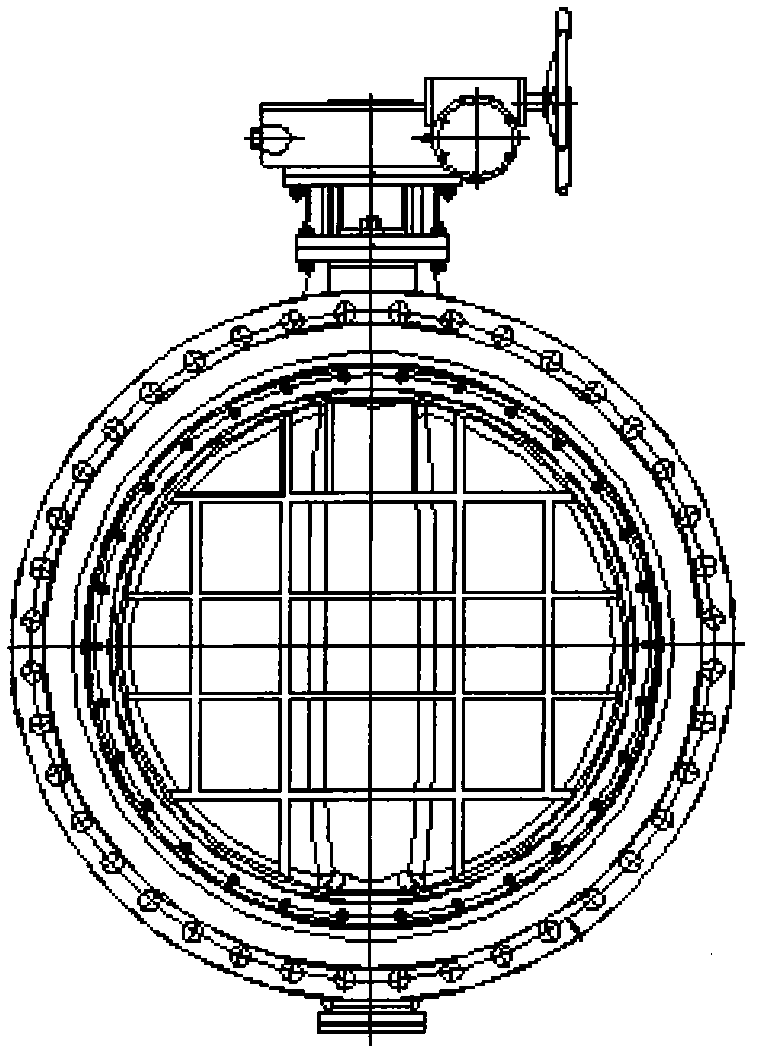

Cast iron eccentric bidirectional sealing butterfly valve

A two-way sealing, eccentric technology, applied in the direction of lift valve, valve device, engine components, etc., can solve the problems of poor welding performance of cast iron, limited applicable environment of butterfly valve, discount of service life, etc., to reduce replacement and downtime, replace floating The effect of convenient seat and reduced precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

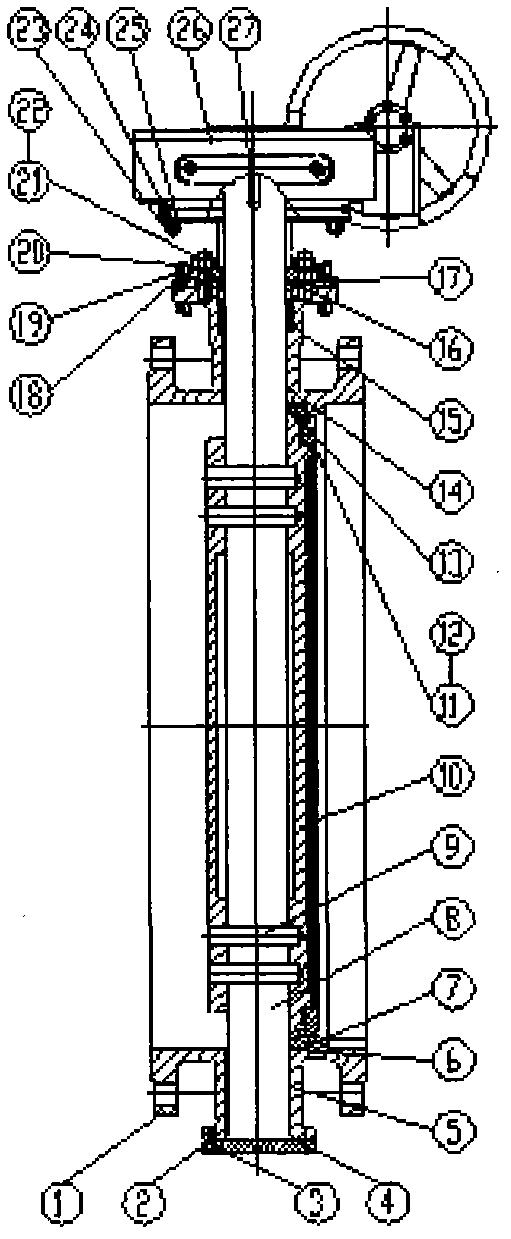

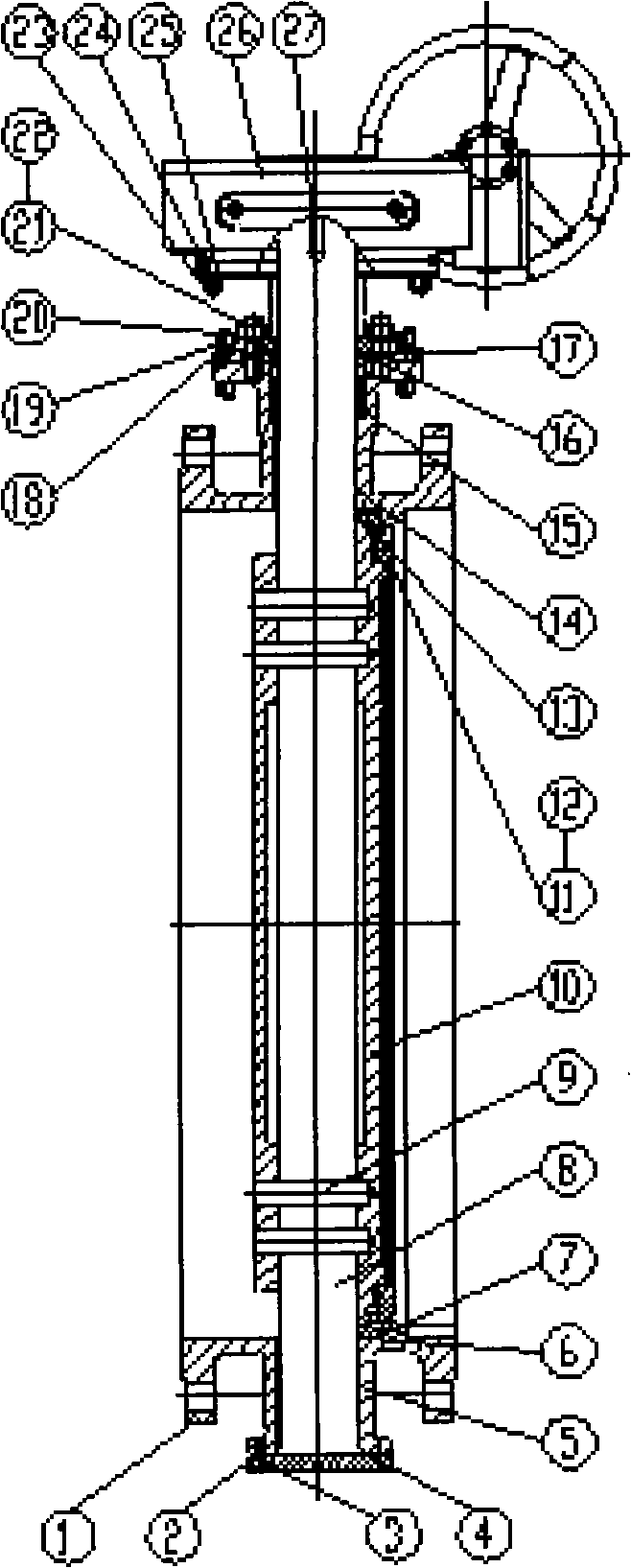

[0024] The present invention is an improvement based on the structural defects of the existing cast iron eccentric butterfly valve. According to the necessary requirements for sealing, a floating valve seat is added (the floating valve seat can be made of a material with higher weldability and corrosion resistance than the valve body, and the sealing The surface can be surfacing with more wear-resistant and corrosion-resistant materials), and the butterfly valve can be sealed in both directions by pushing the floating valve seat to generate a specific pressure greater than the minimum sealing pressure.

[0025] attached figure 2 It is the left side view of the present invention, as shown in the figure, the torque input to the worm gear device 26 (also can be other such as electric device, hydraulic device or handle, etc.) drives the valve stem 8 to rotate through the key 27, and the valve stem torque passes through the cylindrical pin 9 Drive the butterfly plate 10 and multi-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com