Universal water drain valve for air delivery pipe

A technology for drain valves and air pipes, applied to valve details, multi-way valves, valve devices, etc., which can solve problems such as inability to ensure the installation angle of drain valves and one-way valves, twisting, skewing, and malfunction of non-rigid air pipes, etc. , to achieve the effect of eliminating water storage in U-shaped tubes, preventing rupture and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

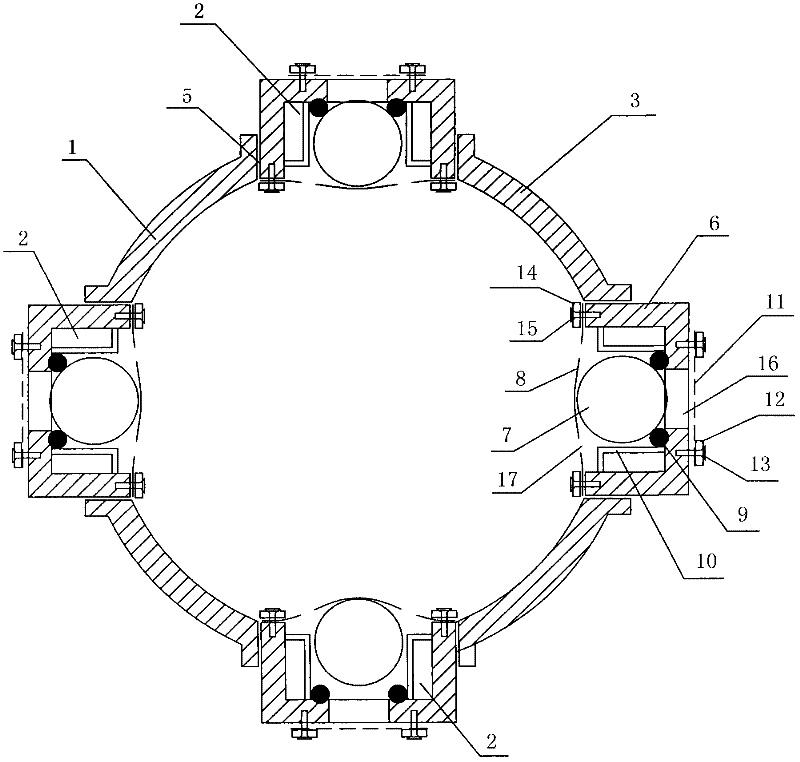

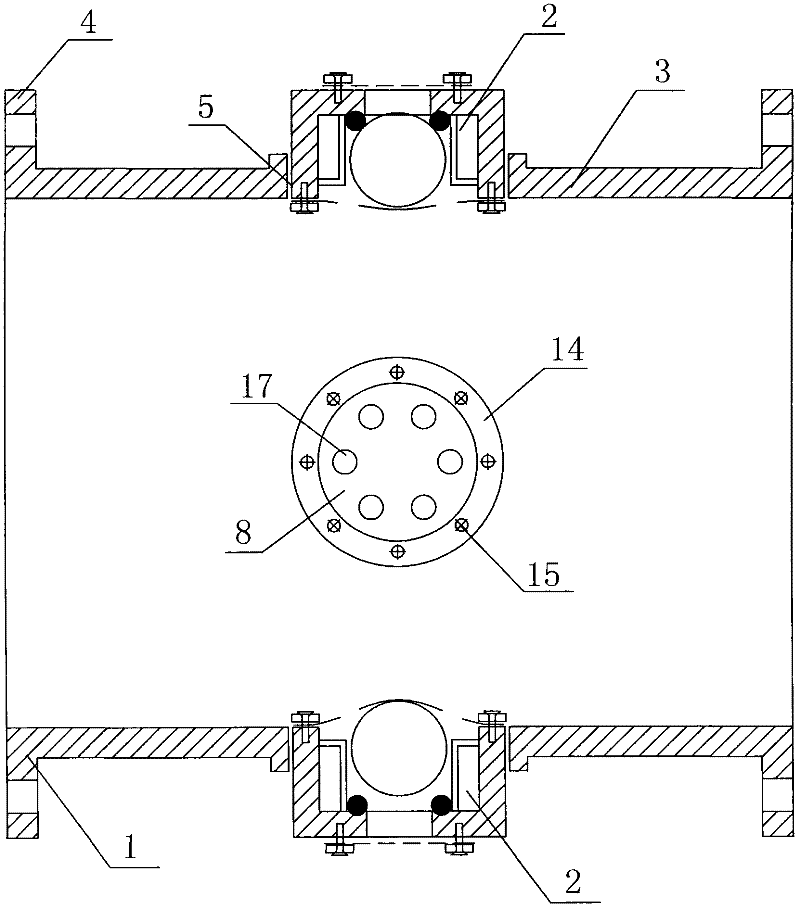

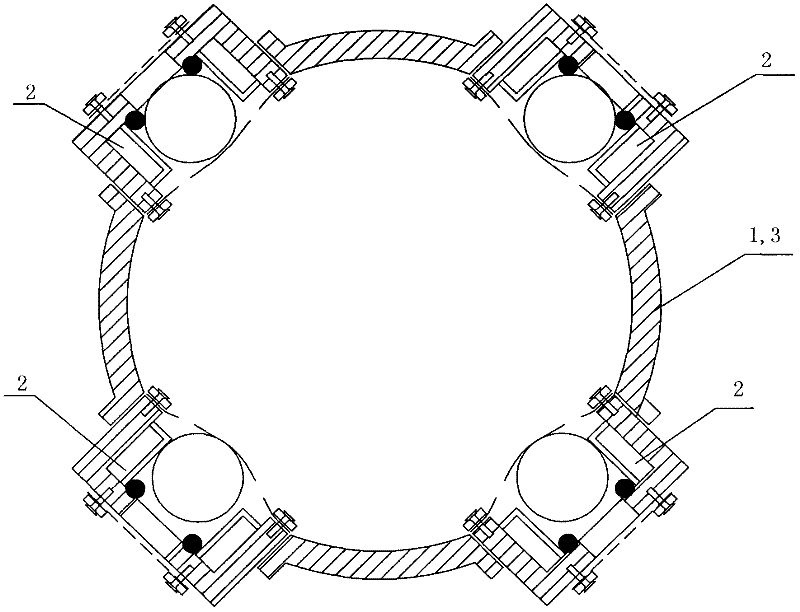

[0019] Such as figure 1 , figure 2 As shown, the universal drainage valve of the gas pipe is composed of a valve housing 1 and four valve cores 2. The valve casing 1 and the valve core 2 are both cylindrical, and the valve core 2 is vertically installed on the valve casing 1. The valve housing 1 is composed of a straight cylinder 3 and a flange 4. There are 4 valve core mounting holes 5 in the circumferential direction of the straight cylinder 3 for installing the valve core 2. The valve core 2 is fixed in the valve core installation hole 5 by threads. The valve housing 1 is connected to the gas pipe through flanges 4 at both ends. The valve housing 1 is made of metal or hard non-metallic materials. Spool 2 is composed of valve shoe 6, floating ball 7, elastic cover 8, O-ring 9, guide rod 10, filter screen 11, filter screen pressure ring 12, outer bolt 13, elastic cover pressure ring 14, and inner bolt 15. . The valve shoe 6 is in the shape of a round tube, one end is open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com