Phase change heat accumulating defrosting system for air source heat pump water heater

An air source heat pump and phase change heat storage technology, which is applied in the types of heat exchangers, heat storage equipment, indirect heat exchangers, etc. The effect of avoiding low-voltage protection shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

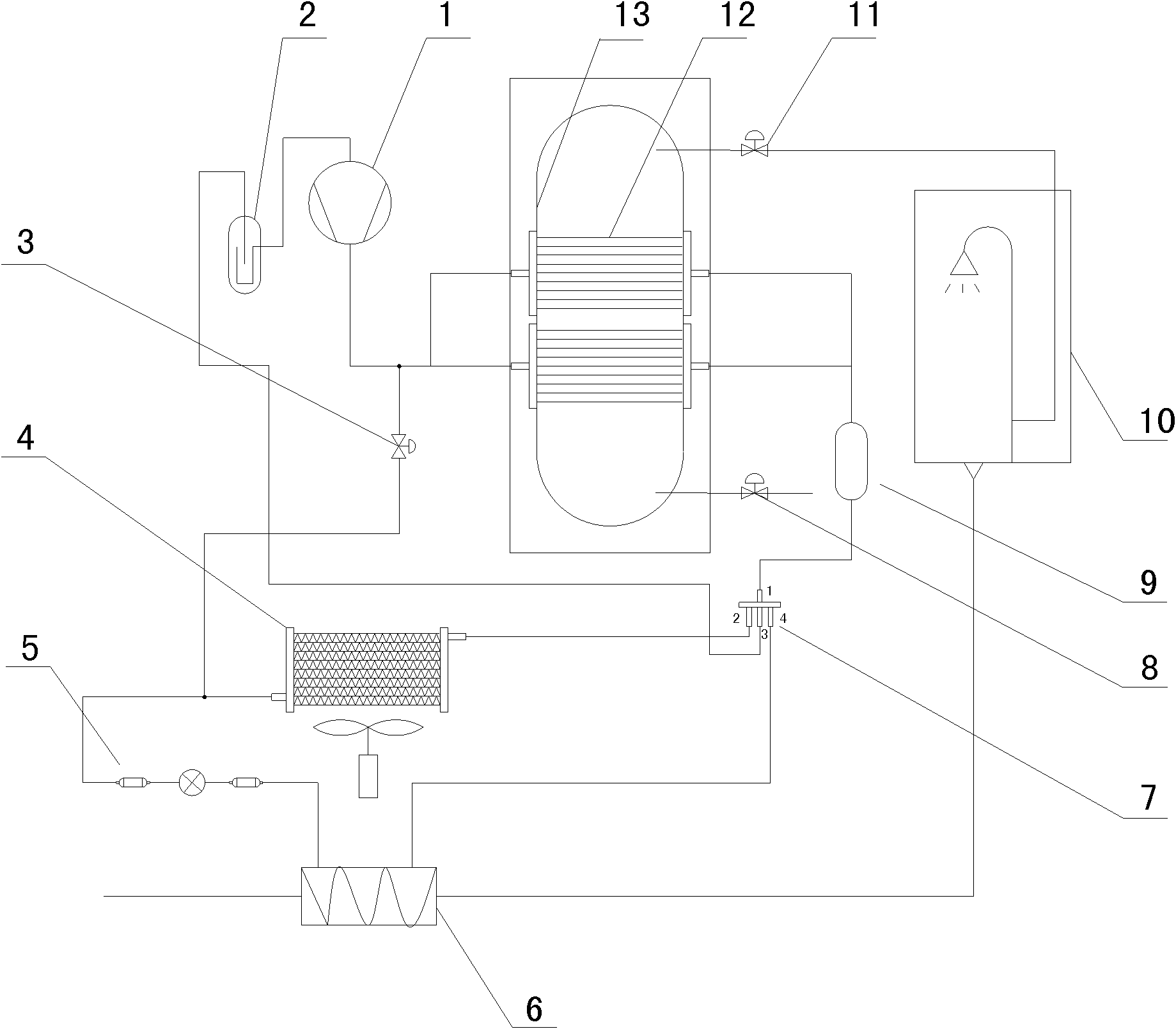

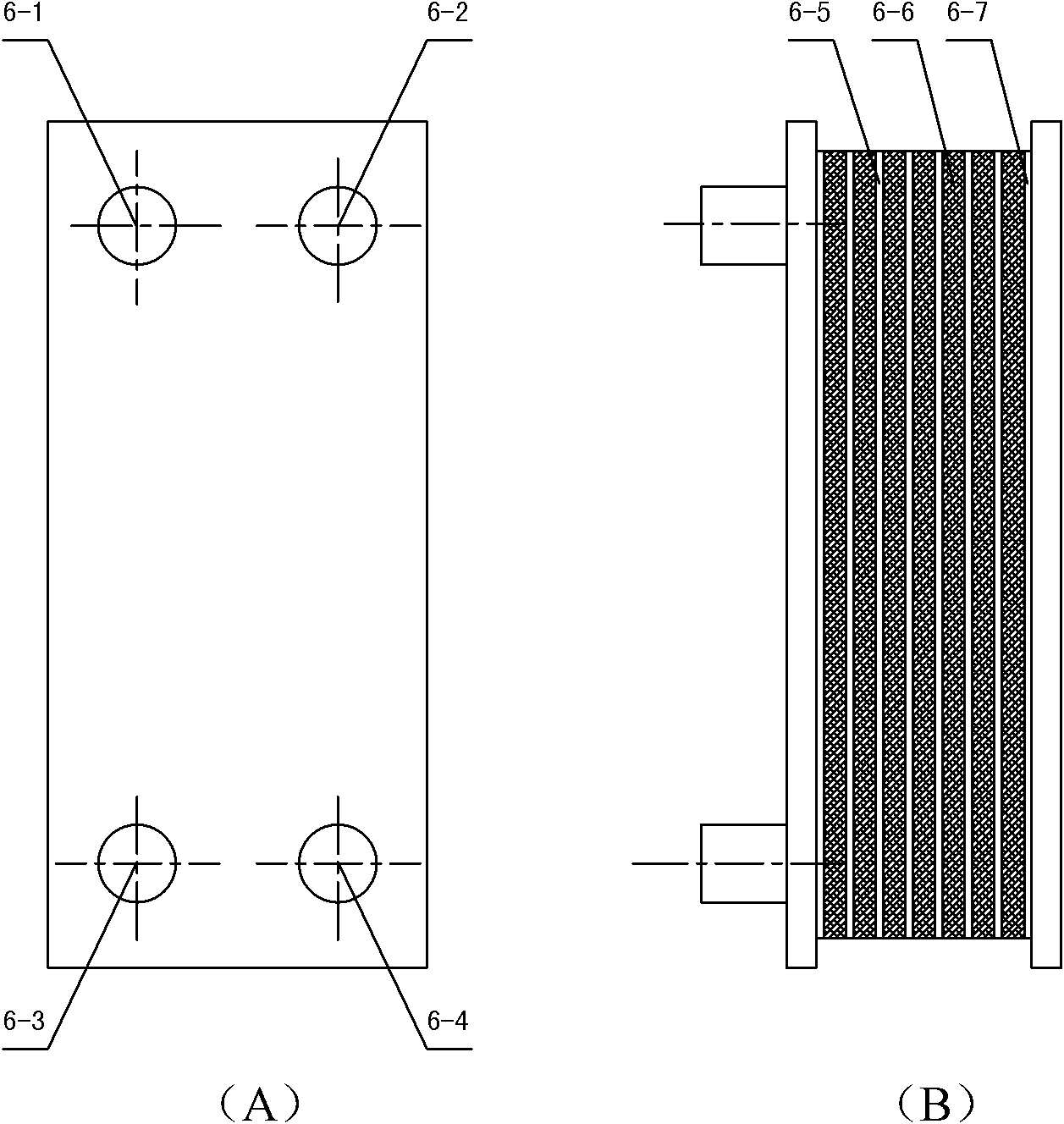

[0023] Implementation Mode 1: Combining figure 1 , figure 2 , the phase change heat storage type defrosting system of the air source heat pump water heater of the present invention comprises a compressor 1, a gas-liquid separator 2, a one-way solenoid valve 3, an outdoor heat exchanger 4, a capillary tube 5, a four-way reversing valve 7, Drying filter 9, external water tank heat exchanger 12, water storage tank 13; the outlet nozzle of the compressor 1 and one end nozzle of the one-way solenoid valve 3 are connected to one end nozzle of the external water tank heat exchanger 12, The input port of the compressor 1 is connected to the output port of the gas-liquid separator 2, the other end of the external water tank heat exchanger 12 is connected to one end of the dry filter 9, and the other end of the one-way solenoid valve 3 One end of the nozzle and the capillary tube 5 is connected to one end of the outdoor heat exchanger 4, the input nozzle of the gas-liquid separator 2 ...

Embodiment approach 2

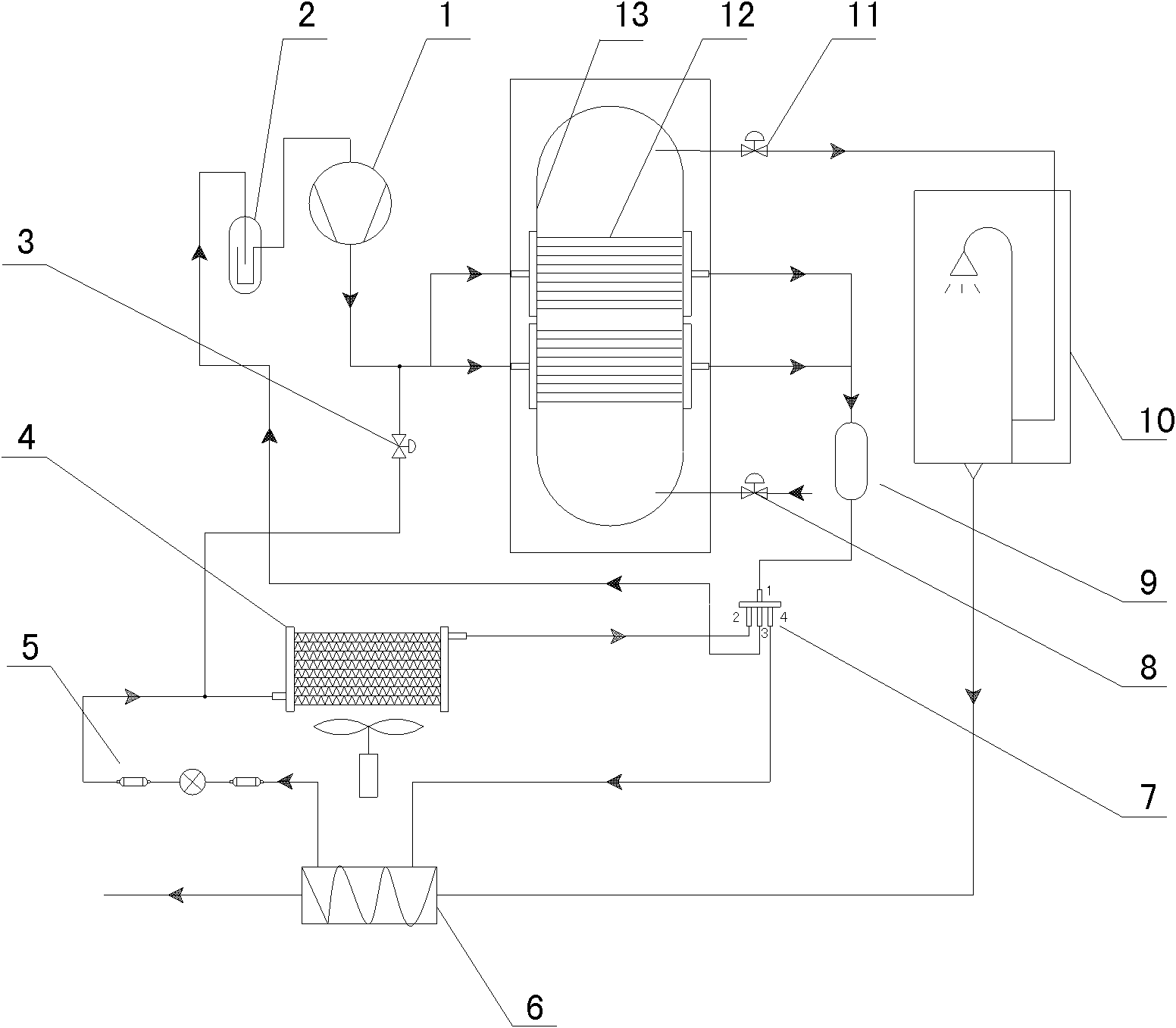

[0048] Implementation Mode 2: Combining figure 1 , figure 2 , image 3 , Explain the working process of waste heat energy storage of the heat storage type defrosting system of the above-mentioned air source heat pump water heater (such as image 3 ).

[0049] The difference from Embodiment 1 is that when the system is in the working state of waste heat energy storage, the system enters from the first input and output port of the four-way reversing valve 7 to the fourth input and output port of the four-way reversing valve 7, and then sequentially After the phase change heat accumulator 6, the capillary tube 5, and the outdoor heat exchanger 4, it returns to the second input and output port of the four-way reversing valve 7, that is, the circulation path of the four-way reversing valve is 1-4-2-3 . The first cut-off valve 8 and the second cut-off valve 11 communicate internally. Other components and connections are the same as those in Embodiment 1.

[0050] When the sys...

Embodiment approach 3

[0051] Implementation Mode Three: Combining figure 1 , figure 2 , Figure 4 , Explain the heat storage type defrosting system release energy defrosting working process of the above-mentioned air source heat pump water heater (such as Figure 4 ).

[0052] The difference from Embodiment 1 is that when the system is in the working state of energy release and defrosting, the system enters from the first input and output port of the four-way reversing valve 7 to the second input and output port of the four-way reversing valve 7, and then After passing through the outdoor heat exchanger 4, capillary tube 5, and phase change heat accumulator 6 in turn, it returns to the fourth input and output port of the four-way reversing valve 7, that is, the circulation path of the four-way reversing valve is 1-2-4- 3. The first cut-off valve 8 and the second cut-off valve 11 communicate internally. Other components and connections are the same as those in Embodiment 1.

[0053] When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com