Lens component for electronic sensor optical imaging device and location method thereof

An electronic sensor and optical imaging technology, which is applied to color TV parts, TV system parts, electrical components, etc., can solve the problems of complex production process, high cost, unfavorable miniaturization, etc., and achieve low material cost and low production cost. Low cost and the effect of preventing adverse phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the missing parts are two rectangles or two triangles or two fan-shaped or two irregular figures, and the two missing parts are arranged on two opposite sides. top corner or opposite sides.

Embodiment 2

[0034] Embodiment 4: The difference between this embodiment and Embodiment 1 is that the missing parts are three rectangles or three triangles or three fan shapes or three irregular figures.

Embodiment 3

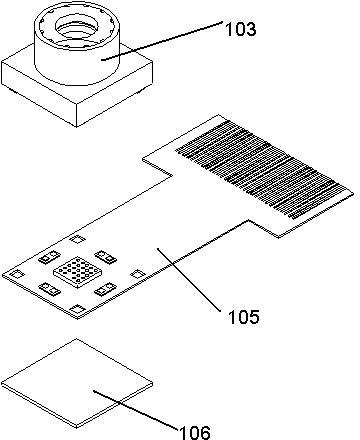

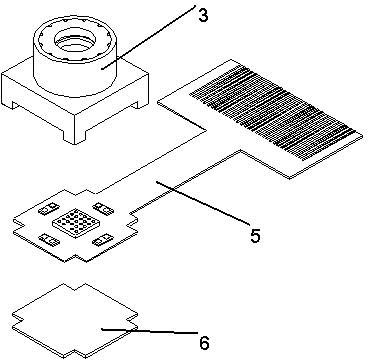

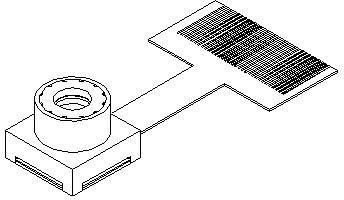

[0035] Embodiment 5: as Figure 6 to Figure 9 , a lens assembly of an electronic sensor optical imaging device, including a base 3, a sensor, and an FPC5 connected in sequence, and also includes a soft board reinforcement board 6, and the soft board reinforcement board 6 is fixedly arranged on the side of the FPC5 that is not connected to the sensor On the one hand, a raised portion is provided on the edge of the base 3 , and the raised portion is tightly connected with the periphery of the FPC 5 and the soft board reinforcing plate 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com