Building block large-power LED tunnel lamp

A technology of LED tunnel lights and LED lamp beads, applied in cooling/heating devices of lighting devices, outdoor lighting, lighting and heating equipment, etc., can solve the problems of energy saving and emission reduction, large-scale promotion, etc., and reduce maintenance costs , reduce development costs, and facilitate large-scale promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

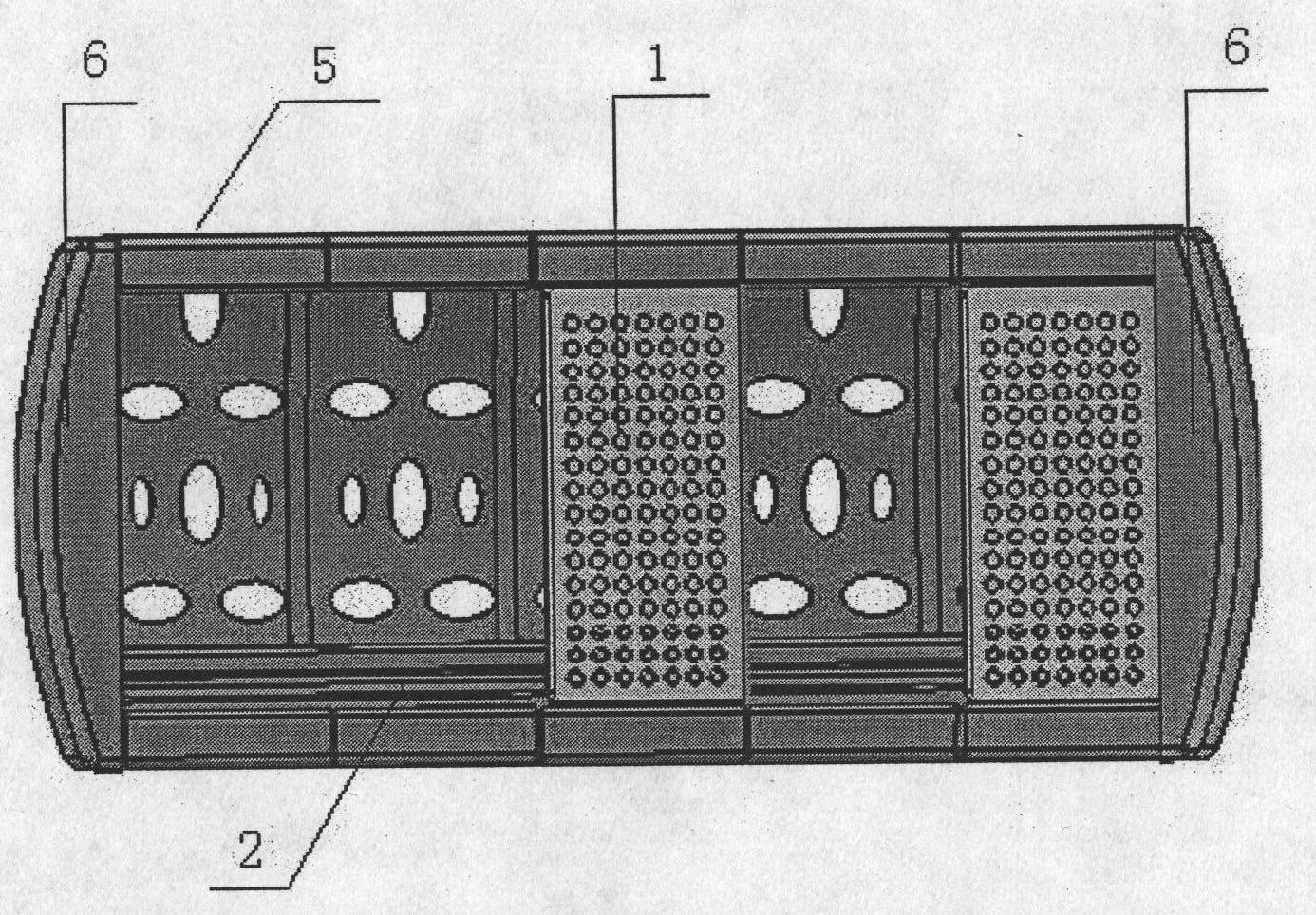

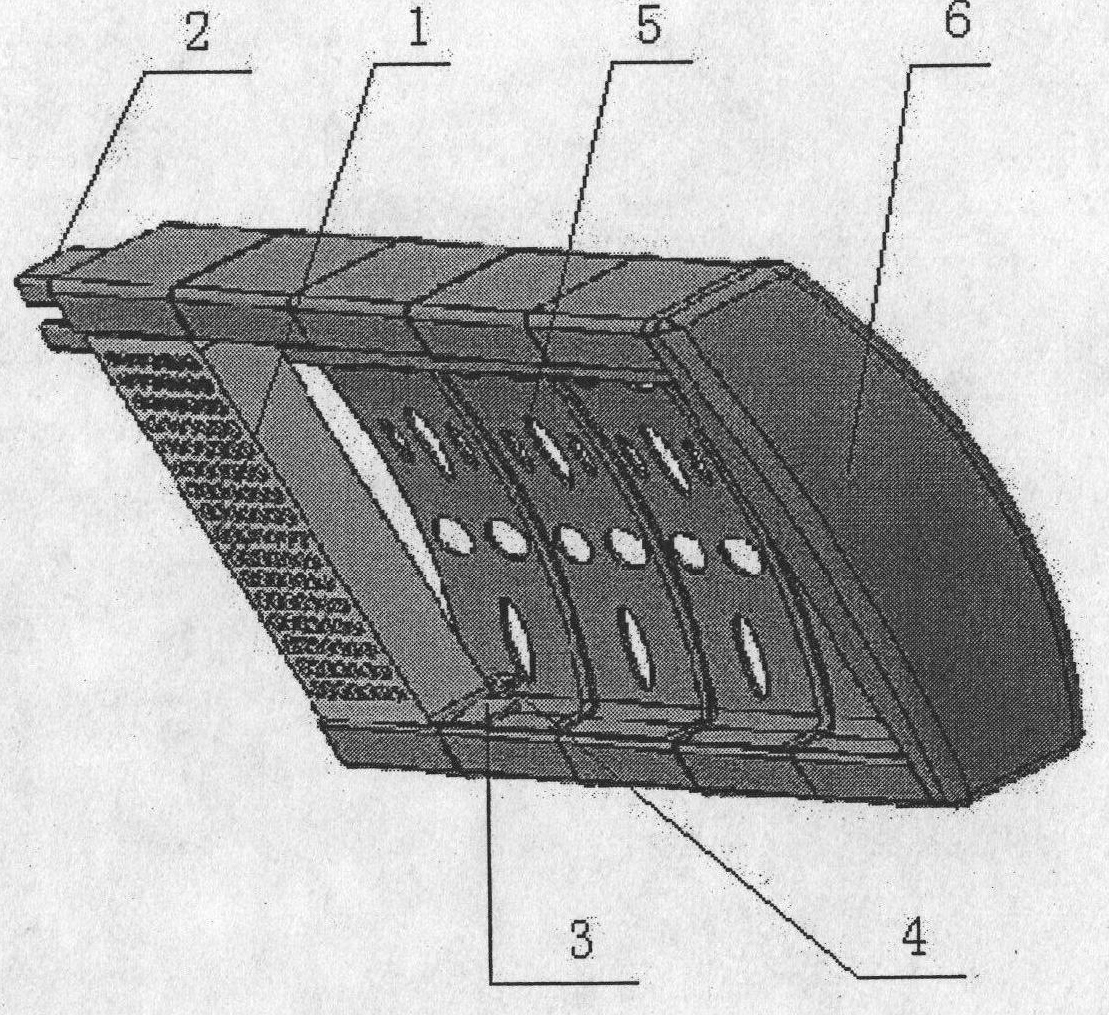

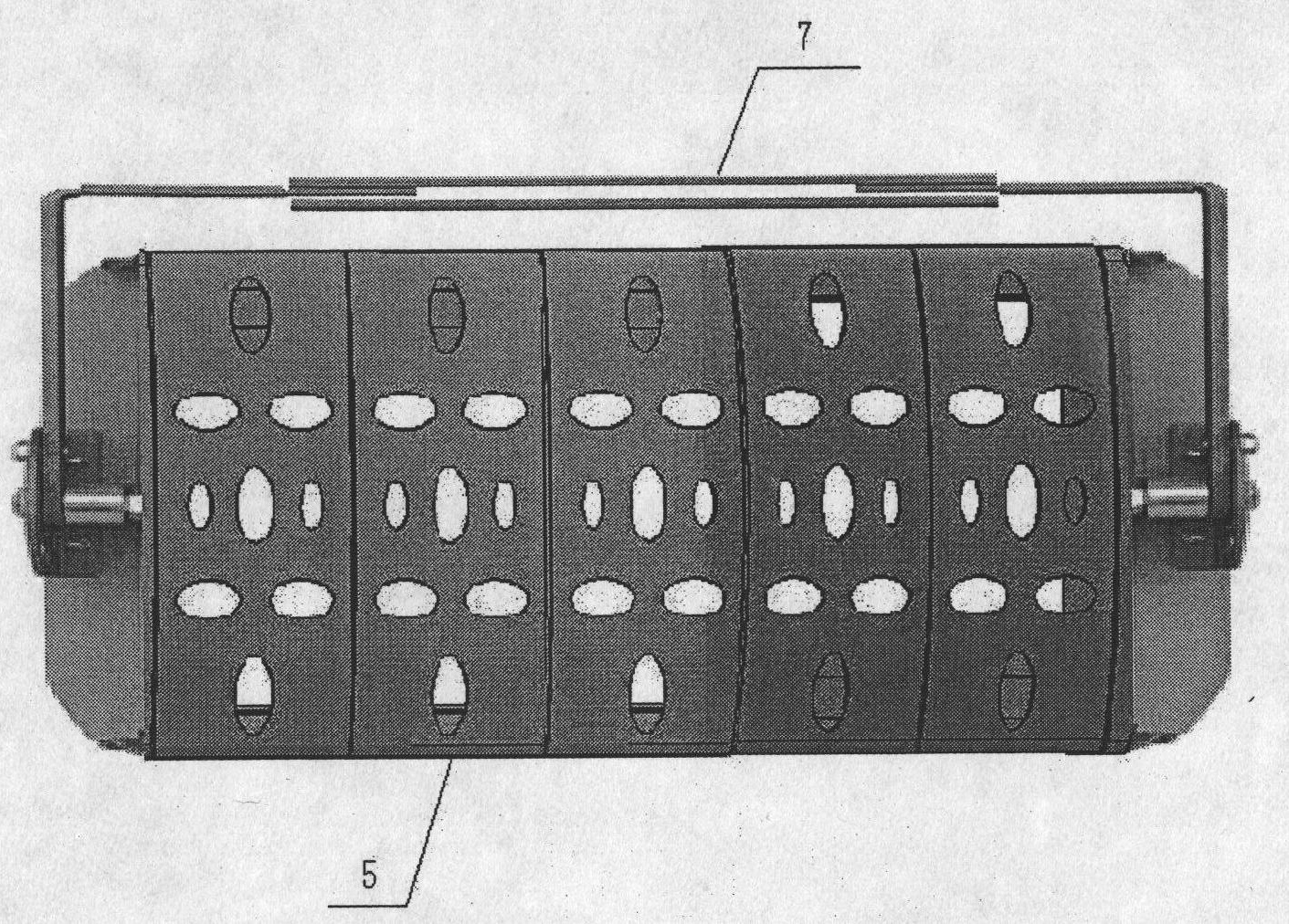

[0030] The invention discloses a building block type LED tunnel light. It is as convenient as stacking blocks. Such as figure 1 , figure 2 and image 3 As shown, the building block LED tunnel light includes a module 1 , a skeleton 2 , a fixing clip 3 , a module bracket 4 , a module cover plate 5 , an end plate 6 and a lamp body bracket 7 . The cover plate 5 and the end plate of the lamp body module are made of punched 1mm aluminum plate, which has the advantages of light weight, corrosion resistance and the like. The connection between the modules is connected with the module bracket 4 through the skeleton 2, the fixing clip 3, and finally the end plate 6 is connected. It can be connected in any number like building blocks as needed. The module cover plate 5 only plays an aesthetic and dust-proof effect, and does not have a heat dissipation effect. This is the essential difference from other structures of LED tunnel lights, because if the shell is a heat sink, it will n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com