Novel method and equipment for breaking vacuum of vapor phase drying chamber

A drying tank and air-breaking technology, applied in electrical components, inductance/transformer/magnet manufacturing, circuits, etc., can solve the problems of affecting insulation performance, affecting the quality of charged gas, failing to effectively remove moisture, etc., and achieving air-breaking speed. Faster, shorter time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

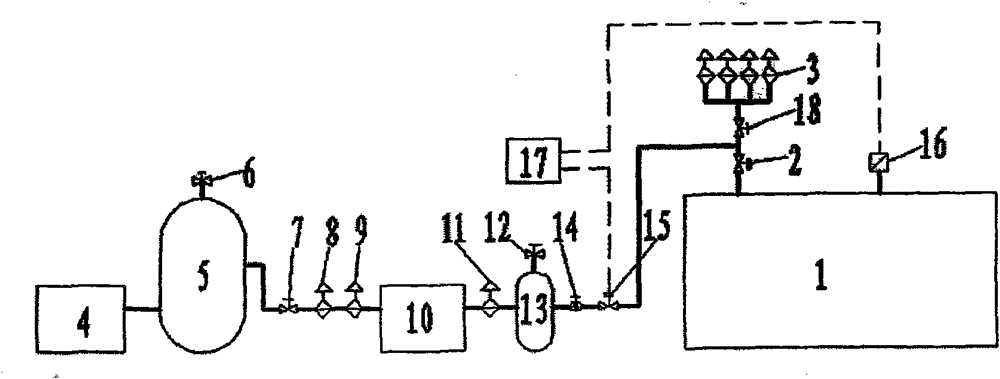

[0032] see figure 1 , the method for breaking the air of the vapor phase drying tank of the present invention, its specific steps are: before breaking the air, start the air compressor 4 in advance, open the dryer inlet valve 7, open the dryer 10, and the compressed air output by the air compressor passes through the dryer The intake valve 7, the first and second front compressed air filters 8, 9 enter the dryer for drying; the dry compressed air output by the dryer is filtered by the rear compressed air filter 11 again, and then adjusted to the low pressure side by the pressure reducing valve 14 The pressure indication is 1 bar; when venting, first open the venting valve 2 of the drying pot connected to the drying pot 1, and then open the regulating valve 15 connected to the venting valve 2 and the pressure reducing valve of the drying pot at both ends to perform venting ; The pressure transmitter 16 that is connected with the drying tank 1 continuously detects the pressure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com