Disengaging adjustable safety handle

A safe and disengaged technology, applied in the starting device with manual crank, engine components, engine starting and other directions, can solve the problems of complex structure of the safety rocker, injuring people due to the reverse rotation of the starting rocker, and unfavorable production. Conducive to sales promotion, simple structure, and beneficial to production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

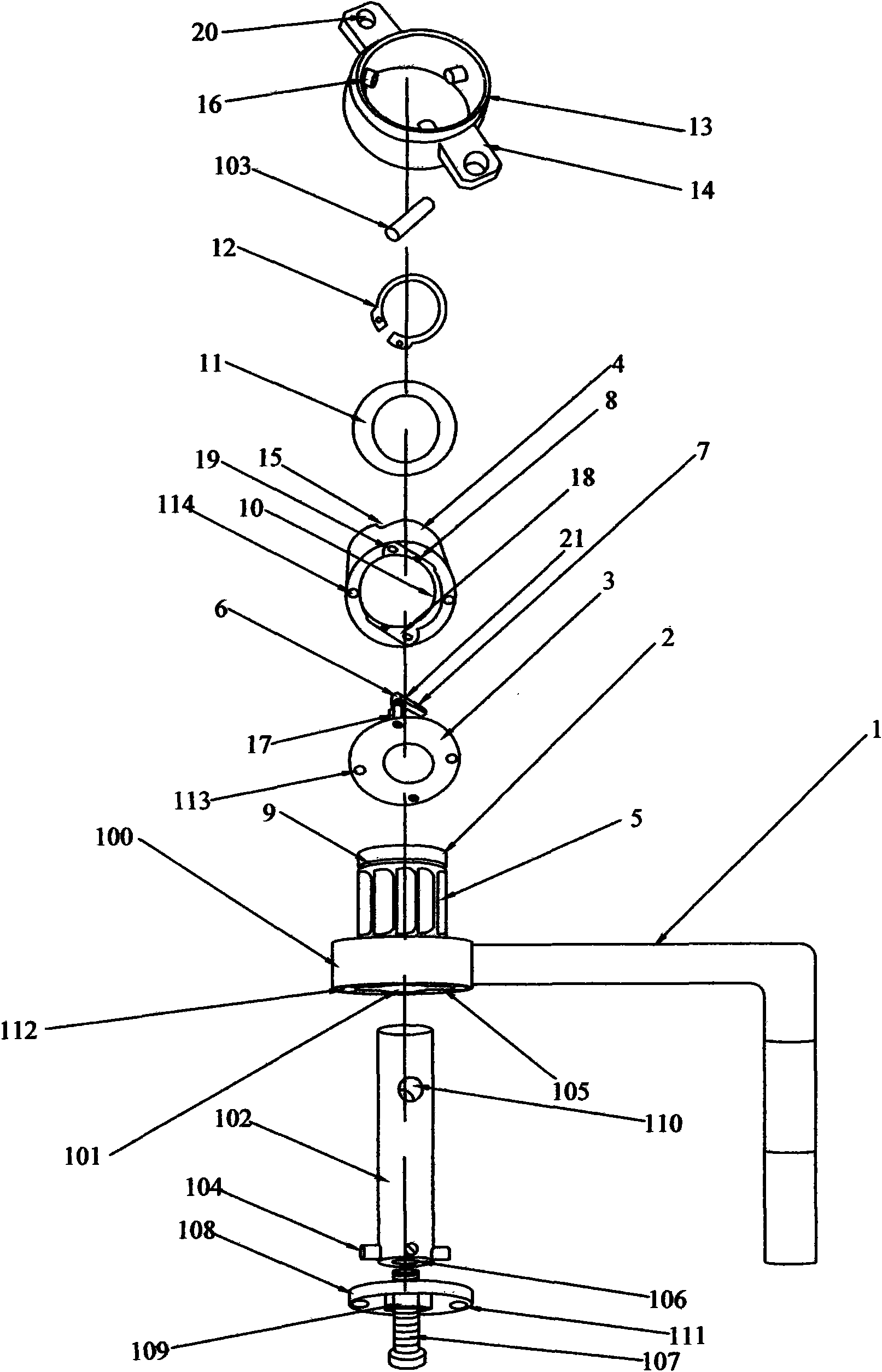

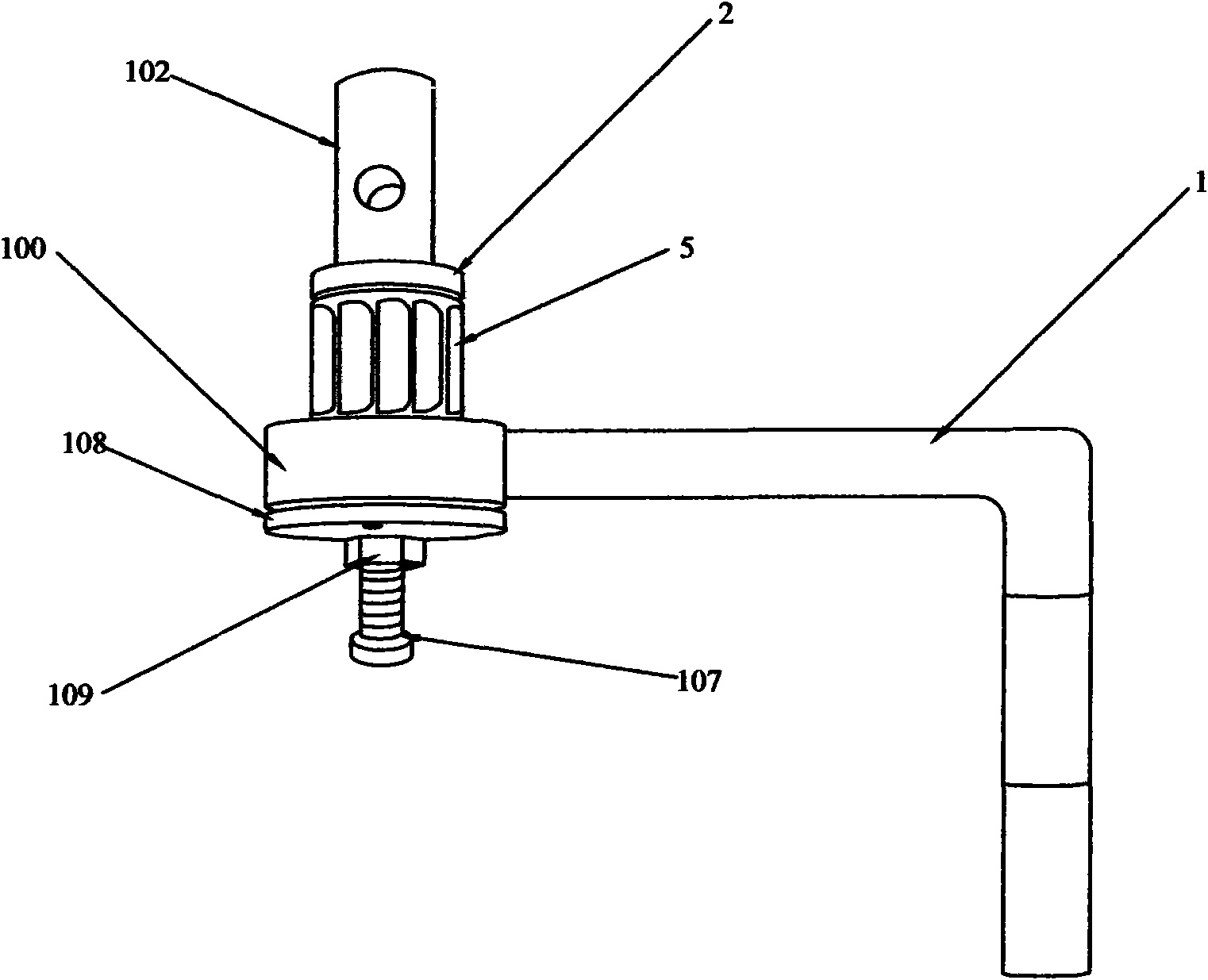

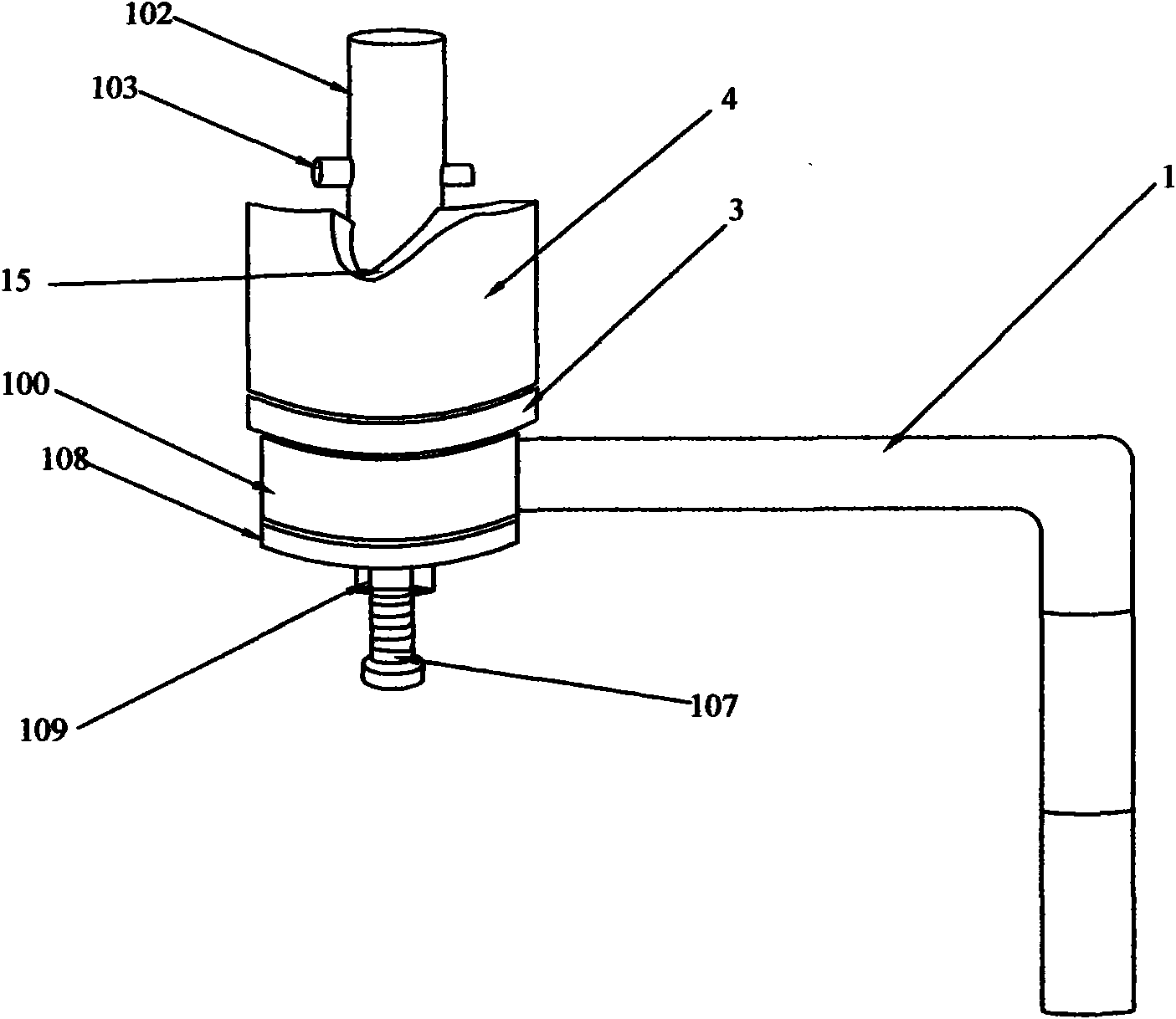

[0022] In order for those skilled in the art to further understand the features and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention.

[0023] see Figure 1 to Figure 5 As shown, the present invention provides a detachable adjustable safety handle, which includes a rocker 1 connected in sequence, a base 100, a shaking head with a starting bushing 2, a chassis 3, an outer cover 4, and a fixed handle for connecting an internal combustion engine body. Seat 13, the starting bushing is fixedly connected to the base, the chassis and the outer sleeve are placed on the starting bushing, wherein the starting bushing 2 is a hollow structure with a through hole 101 in the axial direction, and the through hole 101 runs through the The starting shaft sleeve 2 and the base 100 are pierced with a starting shaft 102, and one end of the starting shaft 102 corresponding to the fixed seat passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com