Heat treatment production process

A manufacturing process and technology to be heated, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

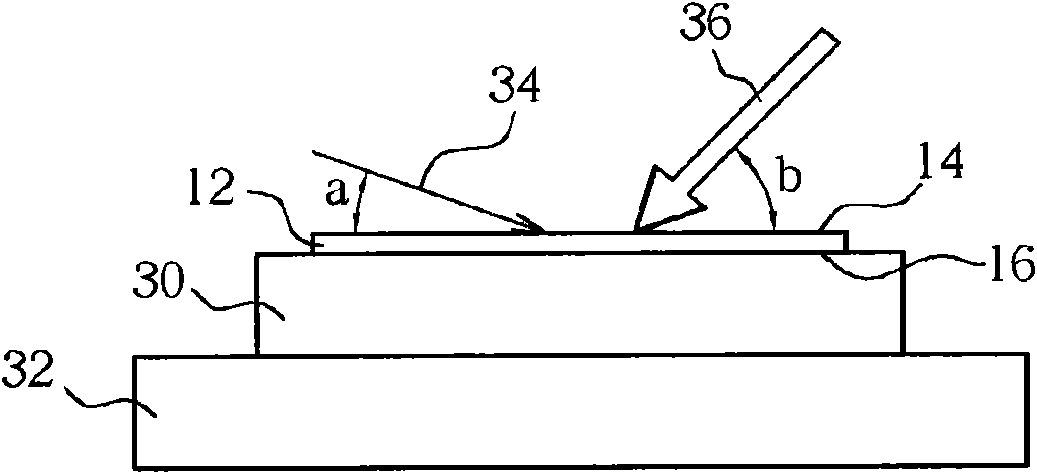

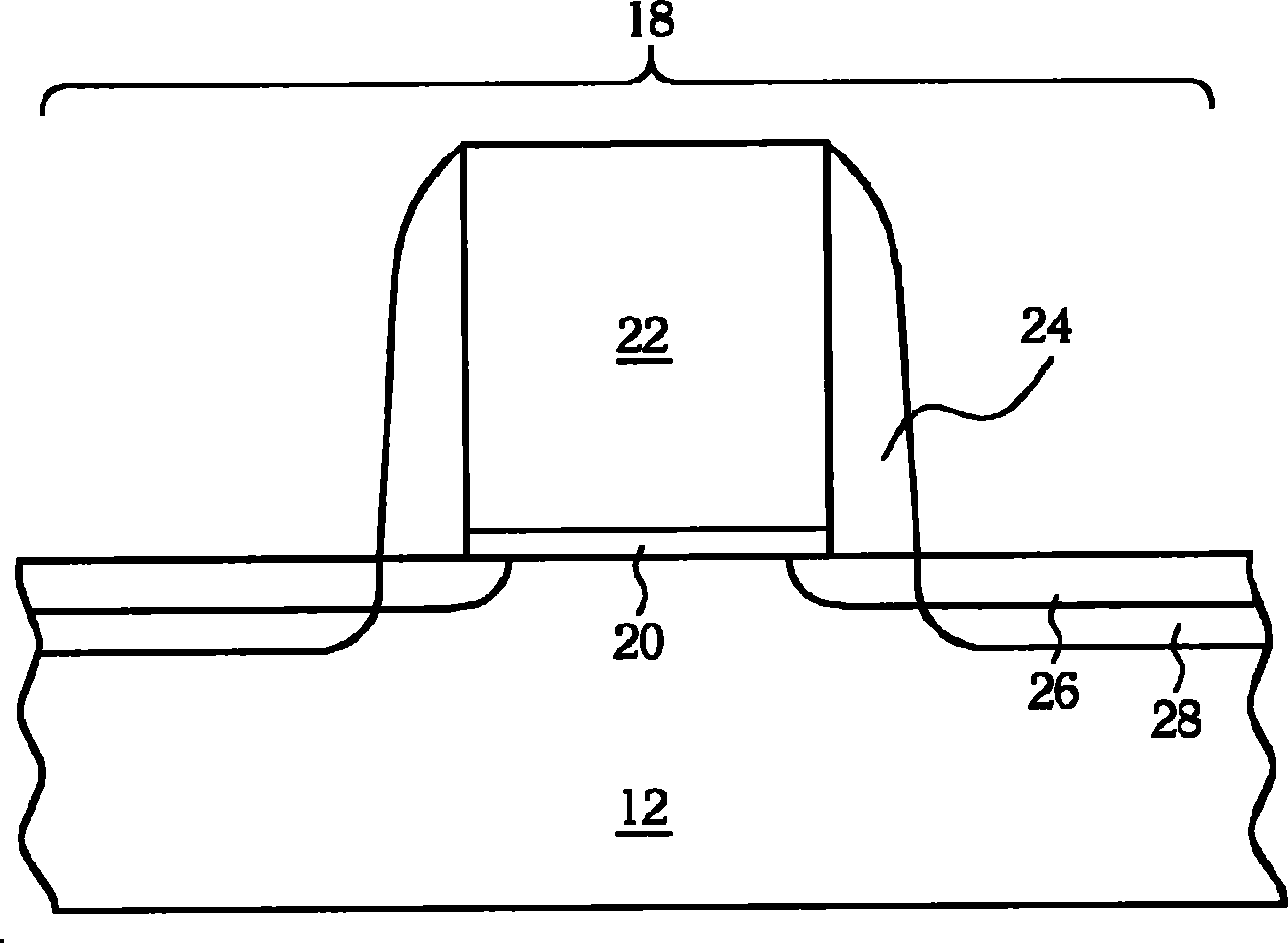

[0033] Please refer to figure 1 and figure 2 , figure 1 It is a schematic diagram of the heat treatment process for a semiconductor substrate to be heated according to the first embodiment of the present invention, figure 2 It is a schematic diagram of a MOS transistor region in the semiconductor substrate. As shown in the figure, firstly, a semiconductor substrate 12 to be heated, such as a silicon wafer, is provided. The semiconductor substrate 12 has a front side 14 and a back side 16 , and a MOS transistor region 18 is defined on the front side 14 . The front surface 14 of the semiconductor substrate 12 of the MOS transistor region 14 is preferably formed with structures such as a gate dielectric layer 20, a gate 22, and a spacer 24, and at least one ion implantation process has been completed, such as a source / drain extension doping process. A doped region (not shown) is in the semiconductor substrate 12 on both sides of the gate 22 or a source / drain doped region (n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com