Inner bore cleaning method and device for plastic packed motor stator

A stator inner hole and cleaning method technology, which is applied in the manufacture of stator/rotor body, etc., can solve the problems of affecting the gap between the plastic-sealed stator and the rotor, affecting the performance index of the plastic-sealed motor, and the friction between the plastic-sealed stator and the rotor, etc., so as to solve the problem of cleaning the surface. Uniform, healthy, clean and bright effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

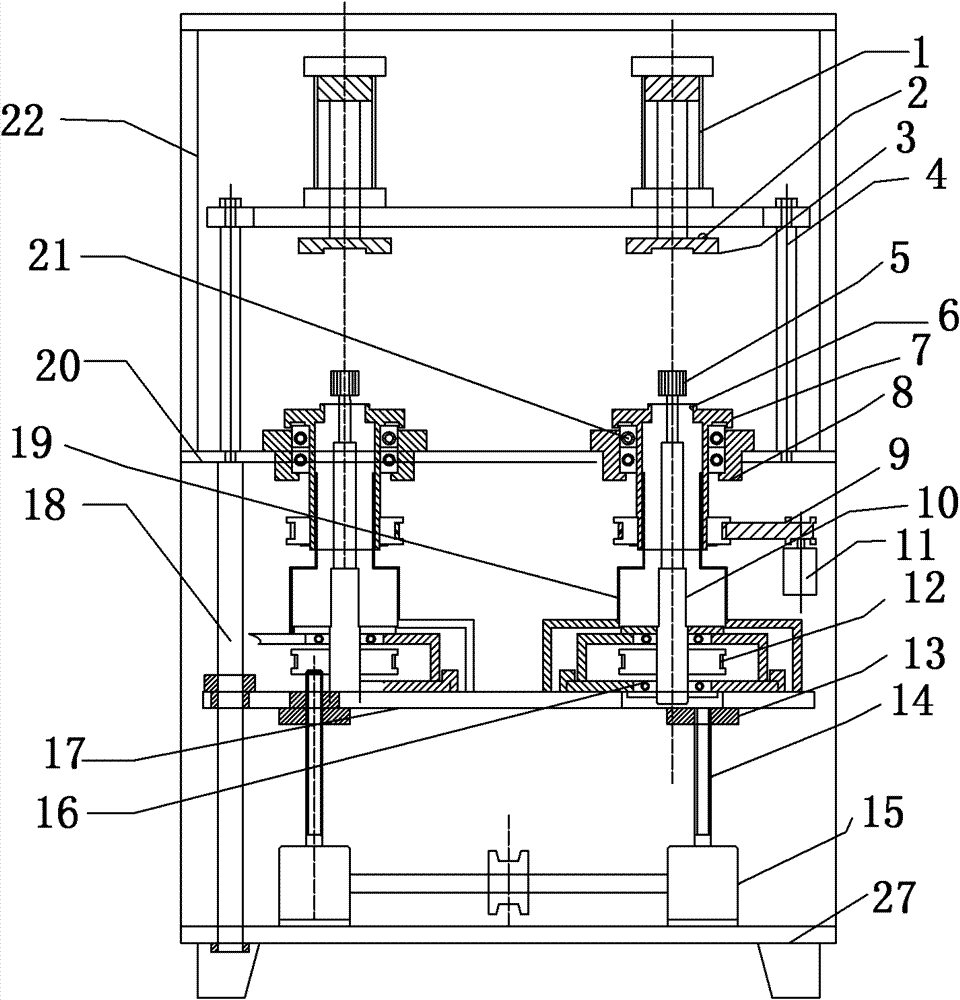

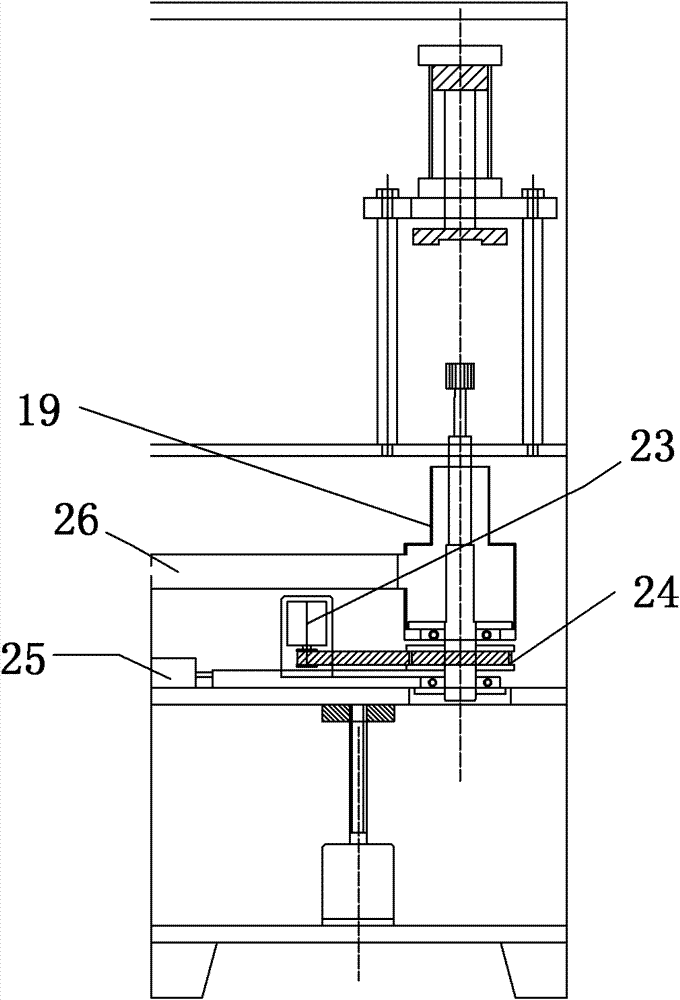

[0028] Example 1. A method for cleaning the inner hole of a plastic-encapsulated motor stator, comprising the following steps:

[0029] ①The cylinder is used to drive the rotatable pressing block to press the stator installed on the stator tooling table, and the stator tooling table is driven by the stepping motor to rotate to make the stator rotate;

[0030] ②The soft grinding head is driven to rotate by the frequency conversion motor, and the rotating direction of the soft grinding head is opposite to that of the stator;

[0031] ③The soft grinding head is radially displaced by pressing the cylinder, and the soft grinding head is displaced axially by the motor through the reducer to drive the screw to rotate, and then the burr on the inner hole of the stator is pinned and ground;

[0032] ④ Use a dust removal device to absorb the dust after deburring;

[0033] ⑤ Use a photoelectric sensor to detect the cleanliness of the inner hole of the stator, so as to achieve the purpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com