Intensive farming raker with rolling cage

A rolling cage and precision tillage harrowing technology, applied in the field of fine tillage and harrowing, can solve problems that affect wheat sowing and emergence, soil is easy to harden, and intensive tillage is difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

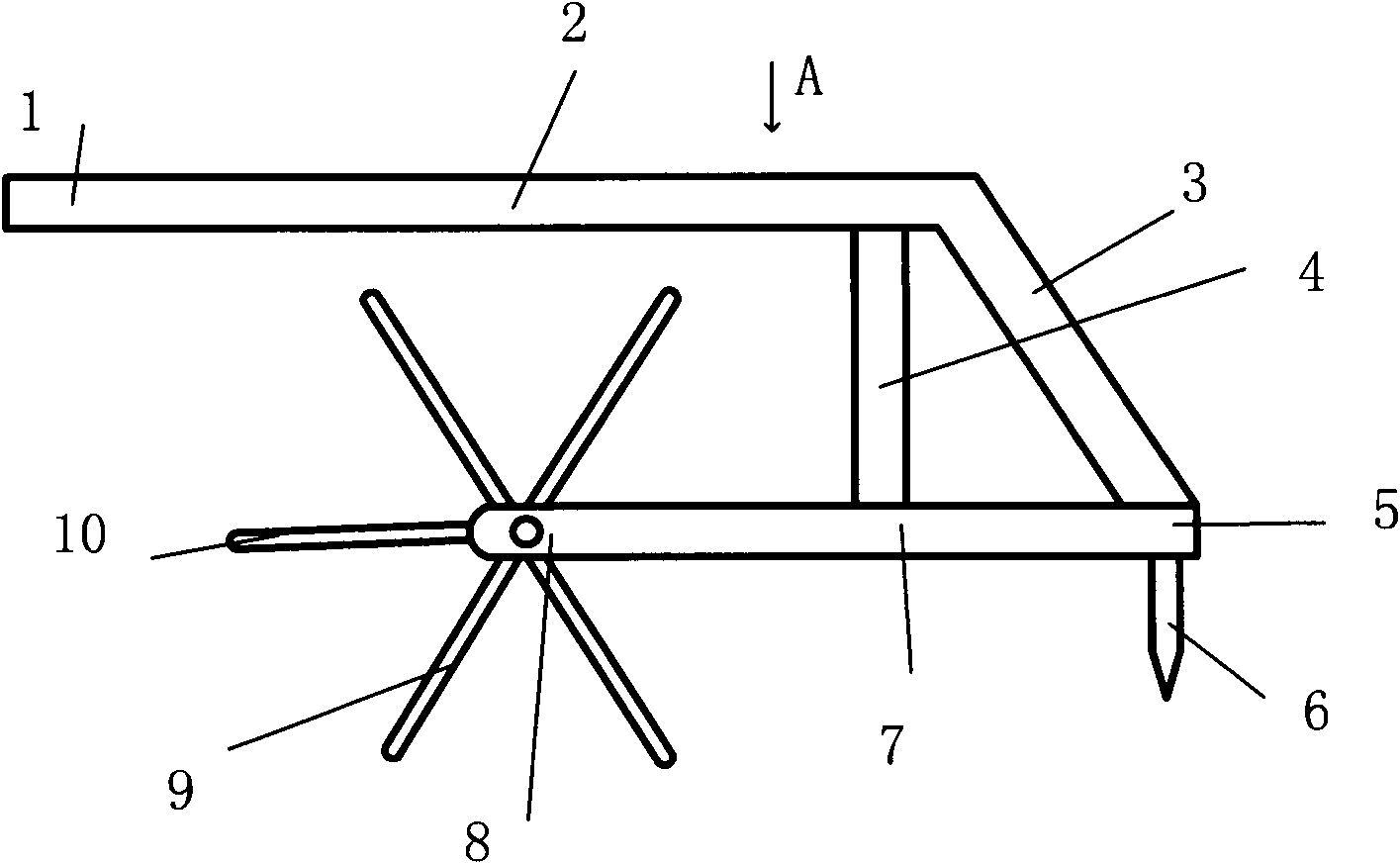

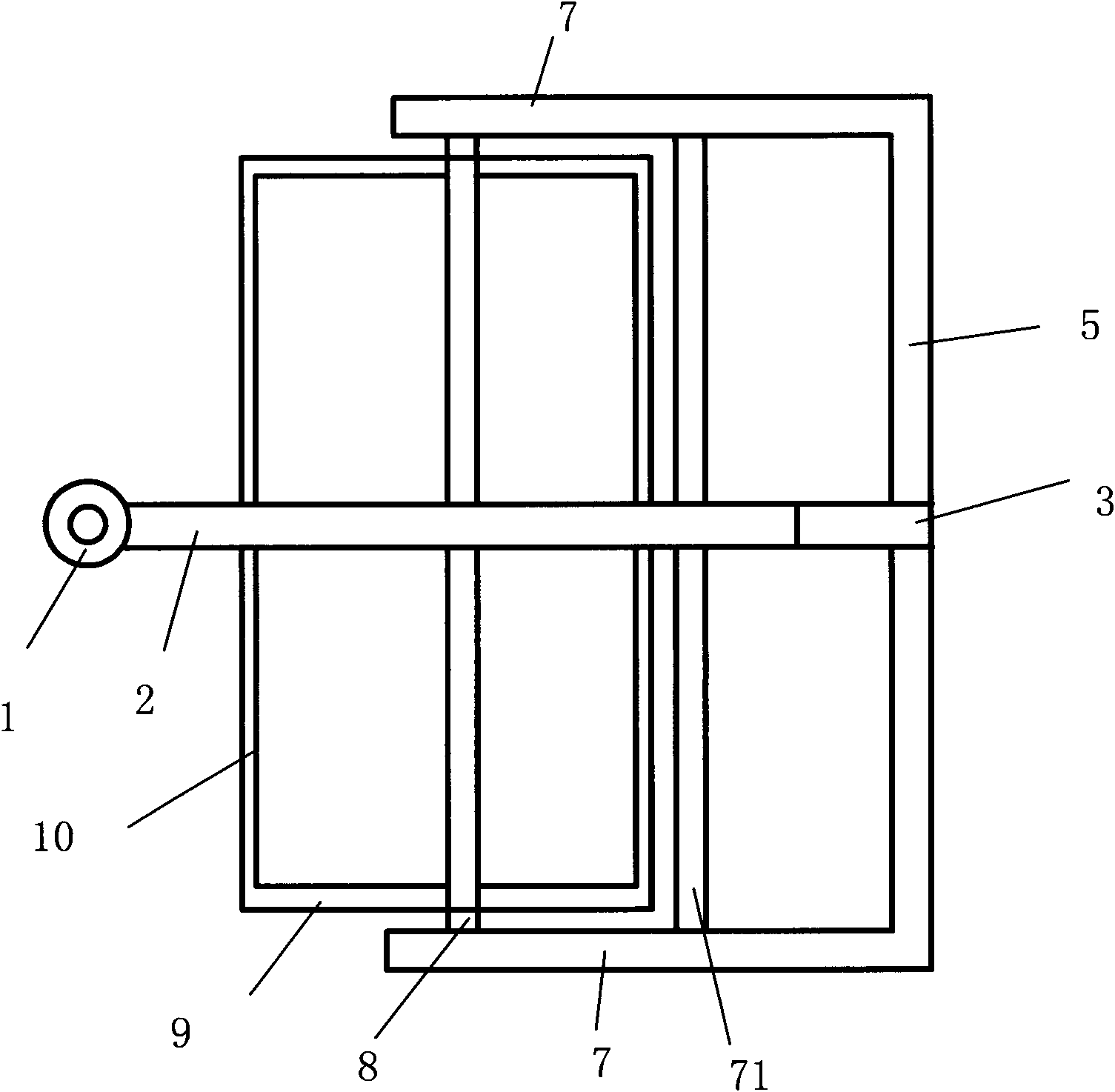

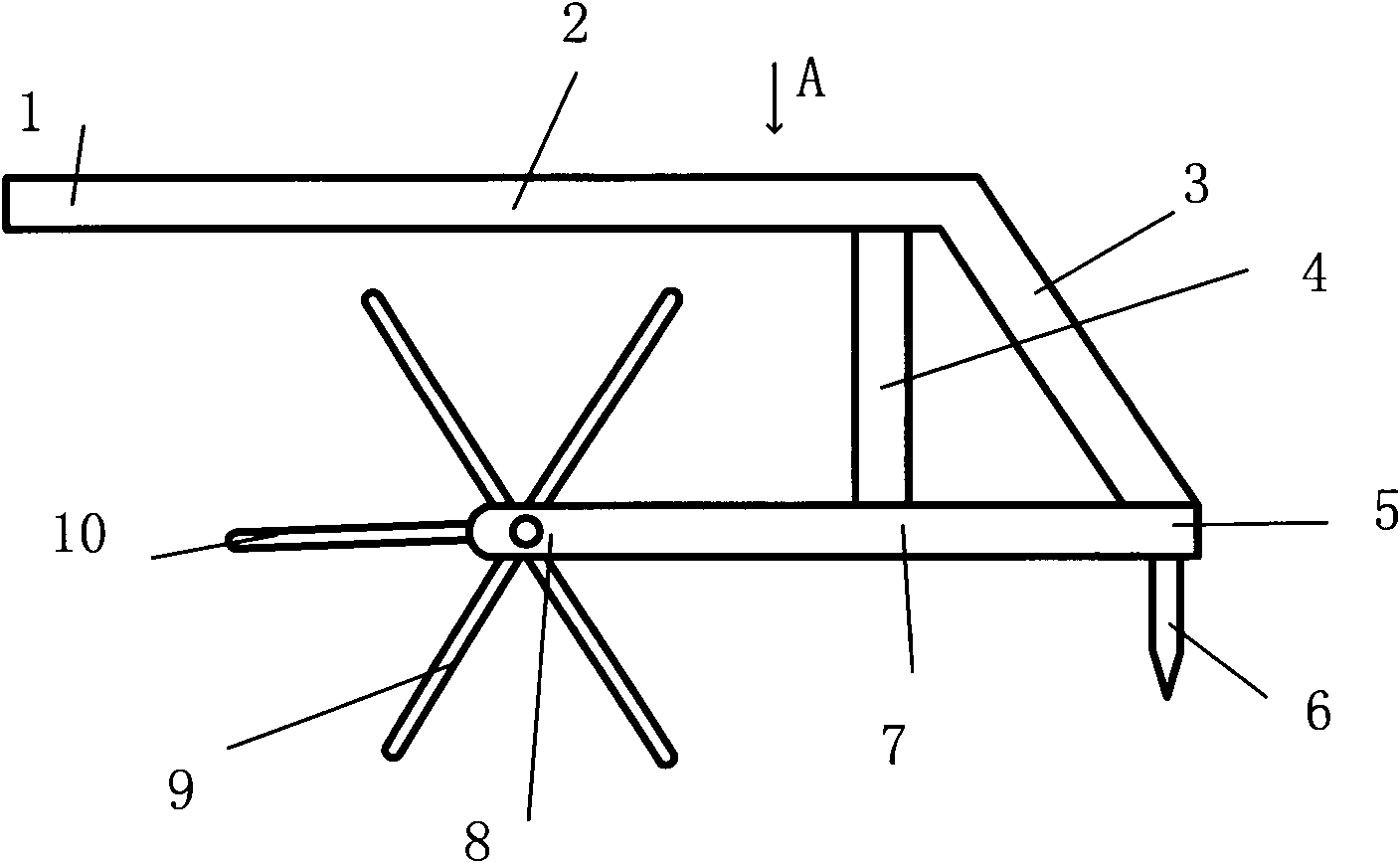

[0010] The precision tillage harrow with a rolling cage according to the present invention is composed of a rake body, a traction bracket 2, and a rolling cage; it is characterized in that: the rake body is a rectangular frame structure, and the two sides of the structure are horizontal frames 7 arranged in parallel, A vertical frame 71 and a side frame 5 are welded in parallel between the horizontal frames 7, and rake teeth 6 are welded or fixed on one side of the side frame 5; The vertical support 4 and the inclined support 3 are welded together with the traction support 2; one end of the traction support 2 is welded with a shaft pin sleeve 1; A number of spokes 9 are evenly arranged on the top of the structure, and wheel bars 10 are arranged in parallel or fixed between the corresponding spokes 9 at both ends of the structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com