Minitype laying device for power cable

A power cable and small technology, which is applied in the field of small power cable laying devices, can solve the problems of large construction machinery being unable to be used normally, and the increase of cable laying workload and cost, so as to avoid building demolition work, improve the standardization operation level, and save operation time. Time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

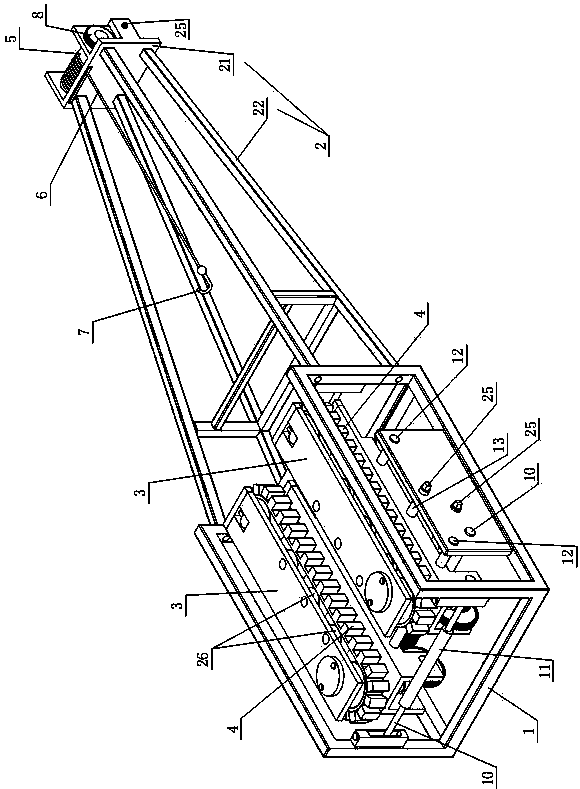

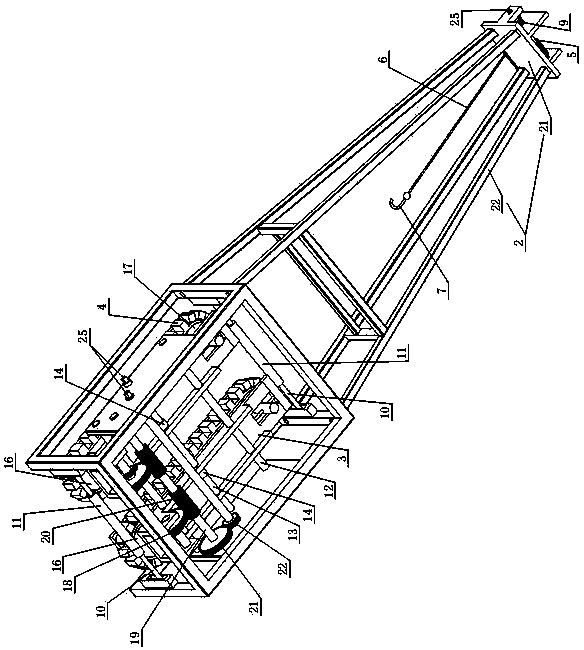

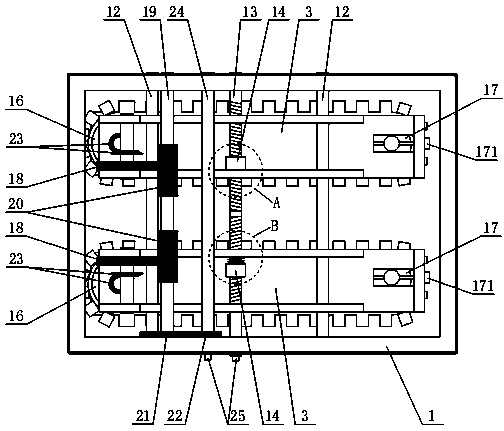

[0023] With reference to the accompanying drawings, one embodiment of the small power cable laying device of the present invention includes a delivery trough 1 and a traction frame 2 detachably connected to the front end of the delivery trough 1, and both ends of the delivery trough 1 in the length direction are open. And a passage for the cables to pass is formed in the conveying trough 1, and the front end of the traction frame 2 is equipped with a traction mechanism that can be connected with the end of the cables.

[0024] Referring to the accompanying drawings, the draw frame 2 includes a draw plate 21 vertically arranged at the front end and a plurality of legs 22 connected to the rear of the draw plate 21. The front ends of the legs 22 are affixed to the draw plate 21, and the rear ends of the legs 22 pass through Bolts or pins are connected with the conveying trough 1. Utilizing the structure of the traction plate 21 and a plurality of legs 22, the traction mechanism c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com