Frying pan and method for preparing frying pan

A frying pan and pot body technology, which is applied to special materials for cooking utensils, cooking utensils, household utensils, etc., can solve the problems of easy falling off, poor strength and fastness, toxic materials, etc., and achieve the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to explain in detail the technical content, structural features, achieved objectives and effects of the present invention, the following will be described in detail in conjunction with embodiments and accompanying drawings.

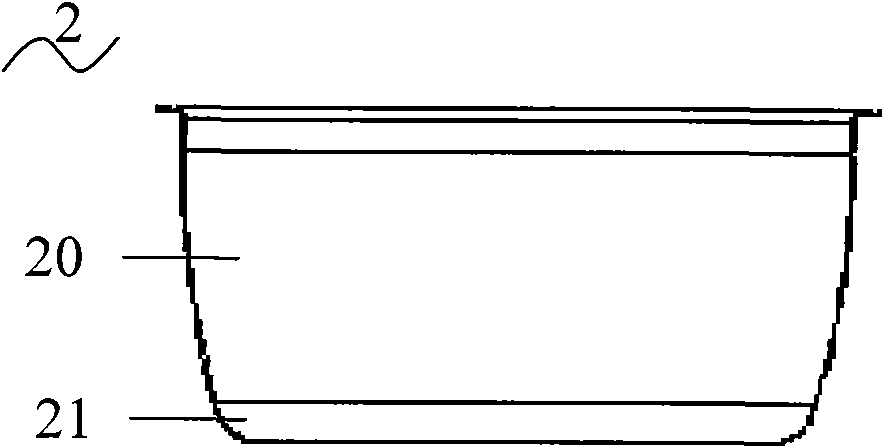

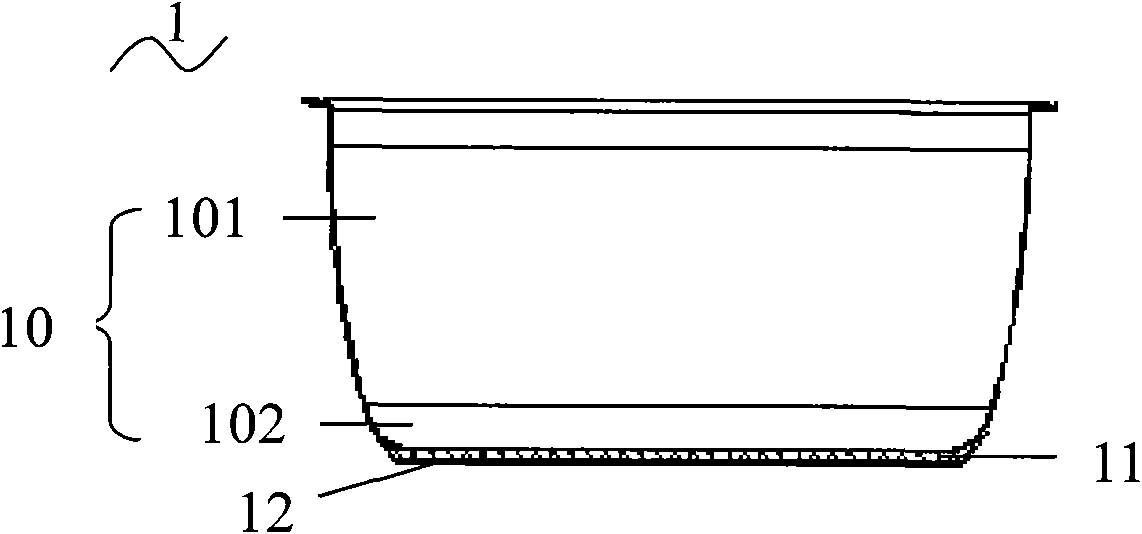

[0015] See figure 2 , figure 2 It is a schematic diagram of the structure of the first frying pan 1. The first frying pan 1 includes a first frying pan precursor 10, and the first frying pan precursor 10 includes a first pan body 101 and a first pan body 101 made of the same material and integrally formed. Heat-receiving layer 102; a second heat-receiving layer 11 longitudinally attached to the bottom of the first heat-receiving layer 102, and a third heat-receiving layer 12 to cover the first heat-receiving layer 102 and the second heat-receiving layer 11. Among them, the first pot body 101 and the first heat receiving layer 102 are made of stainless steel. The second heat receiving layer 11 is made of aluminum. The third heated layer 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com