Glass fiber composite high-tensile fabric

A composite material and woven fabric technology, applied in woven fabrics, textiles and papermaking, etc., can solve the problems of less than 77% effective utilization rate, increase production cost, reduce production efficiency, etc., to improve effective utilization rate, avoid waste, produce Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

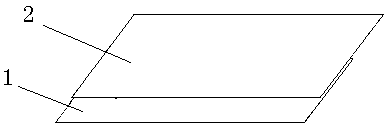

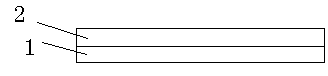

[0015] see figure 1 and figure 2 , this embodiment provides a glass fiber composite high-strength braid (EKT2015), which consists of a triaxial glass fiber composite fabric 1 with a grammage of 1215g per square meter and a double The composition of the axial fiberglass composite fabric 2; in the production process, a layer of 800 grams per square meter is superimposed on the existing general-purpose triaxial fiberglass composite fabric 1 with a grammage of 1215g per square meter The existing general-purpose biaxial fiberglass composite fabric 2, the biaxial fiberglass composite fabric 2 is bundled with the triaxial fiberglass composite fabric 1 through binding yarns, so that the industry can be solved after one production It needs to be produced twice to meet the needs of blades.

[0016] In this embodiment, the biaxial fiberglass composite fabric 2 and the triaxial fiberglass composite fabric 1 are woven from epoxy fiberglass high-strength yarn and polyester yarn, which im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap