Wind power generation building wallboard and construction method

A technology of wind power generation and construction methods, which is applied in wind power generation, renewable energy power generation, construction, etc., can solve problems that affect the appearance of buildings, poor integration of buildings, and restrictions on building structures, and achieve easy maintenance, simple structure, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

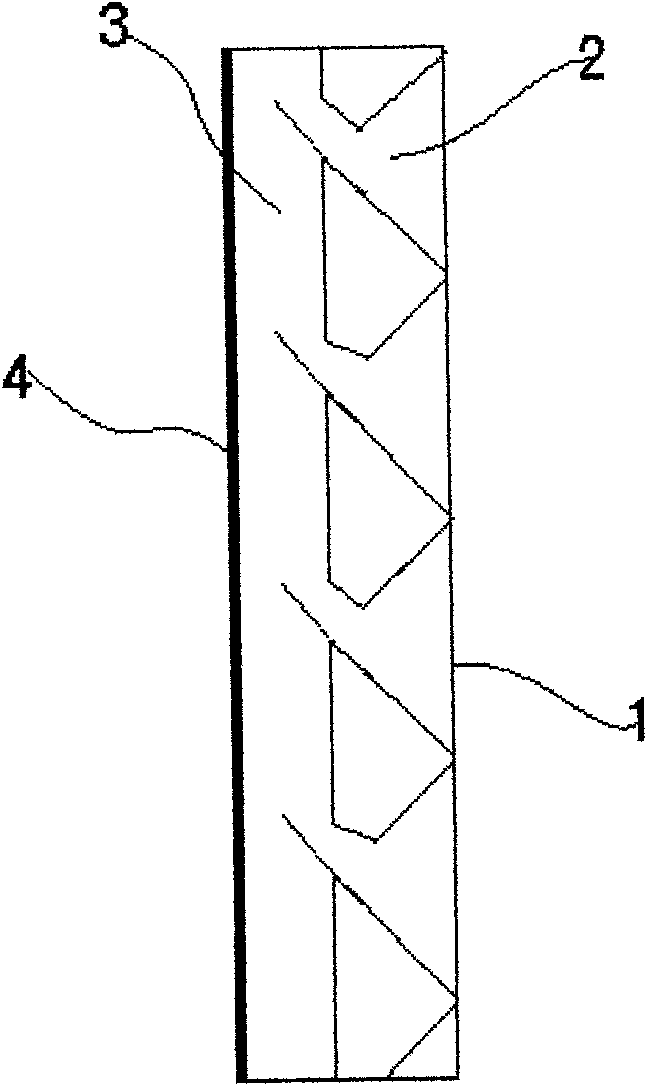

[0019] Embodiment one: if figure 1 As shown, a wind power generation building wall panel module is characterized in that it is composed of a module bracket 1, an air inlet 2, an air collection channel 3, an insulation board 4, and a generator 5.

[0020] Wherein the air inlet 2 has a large opening to the outside, and the mouth leading to the air collecting channel 3 is small, and a section of deflector is extended in the air collecting channel 3, and the normal line of the surface of the deflector is directed obliquely upward relative to the wall surface, so that When the molecules or particles in the air flow collide with the deflector, they will be roughly bounced upward into the air collecting channel 3, and continuously flow upward in the form of air flow.

[0021] Among them, the air collecting channel 3 is a cubic channel in a single wind power generation building wall panel module, and the surface of a section leading to the air inlet is described in the front, and the ...

Embodiment 2

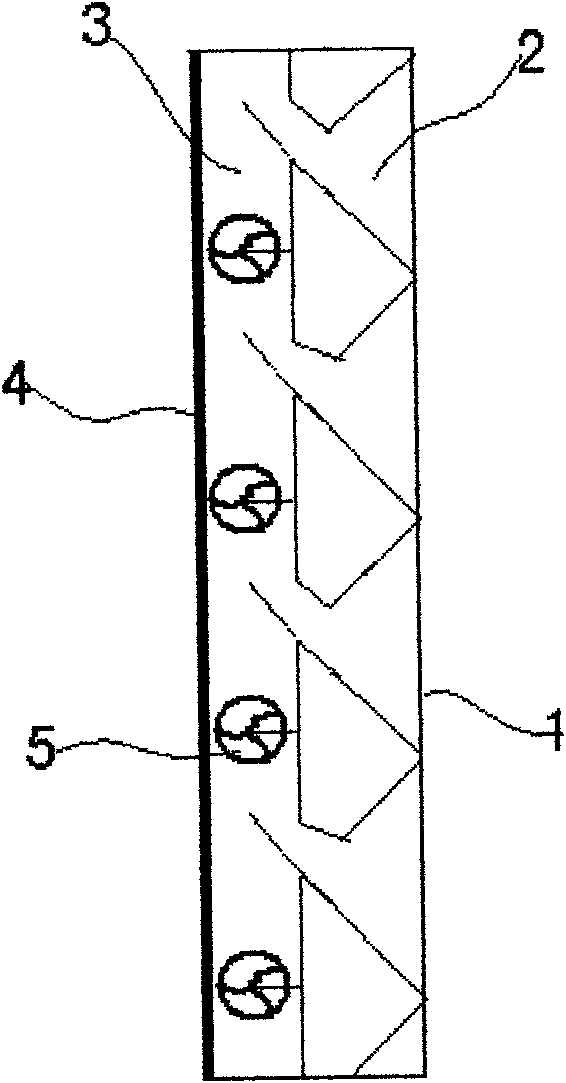

[0024] Embodiment two: if figure 2 As shown, the generators 5 are placed in the air collecting duct 3 and evenly distributed in each module, and the rest of the structures and functions are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com