Portable spliced guide rail, butt joint method and work fixture

A portable and guide rail technology, applied in the field of tooling and fixtures, can solve the problems that the size of the processed workpiece should not be too large, affect the use and sales of the machine, and the quality of splicing cannot be guaranteed, so as to facilitate long-distance transportation, ensure uniqueness and reliability, and improve use. The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

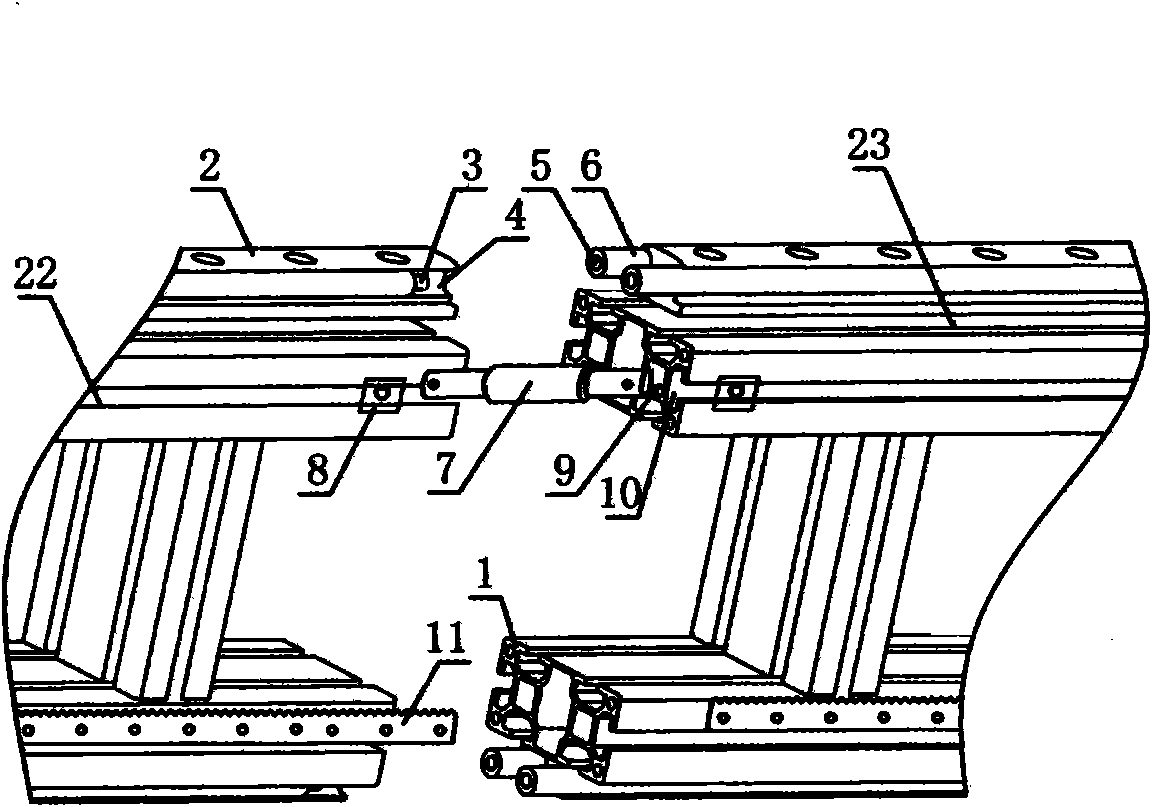

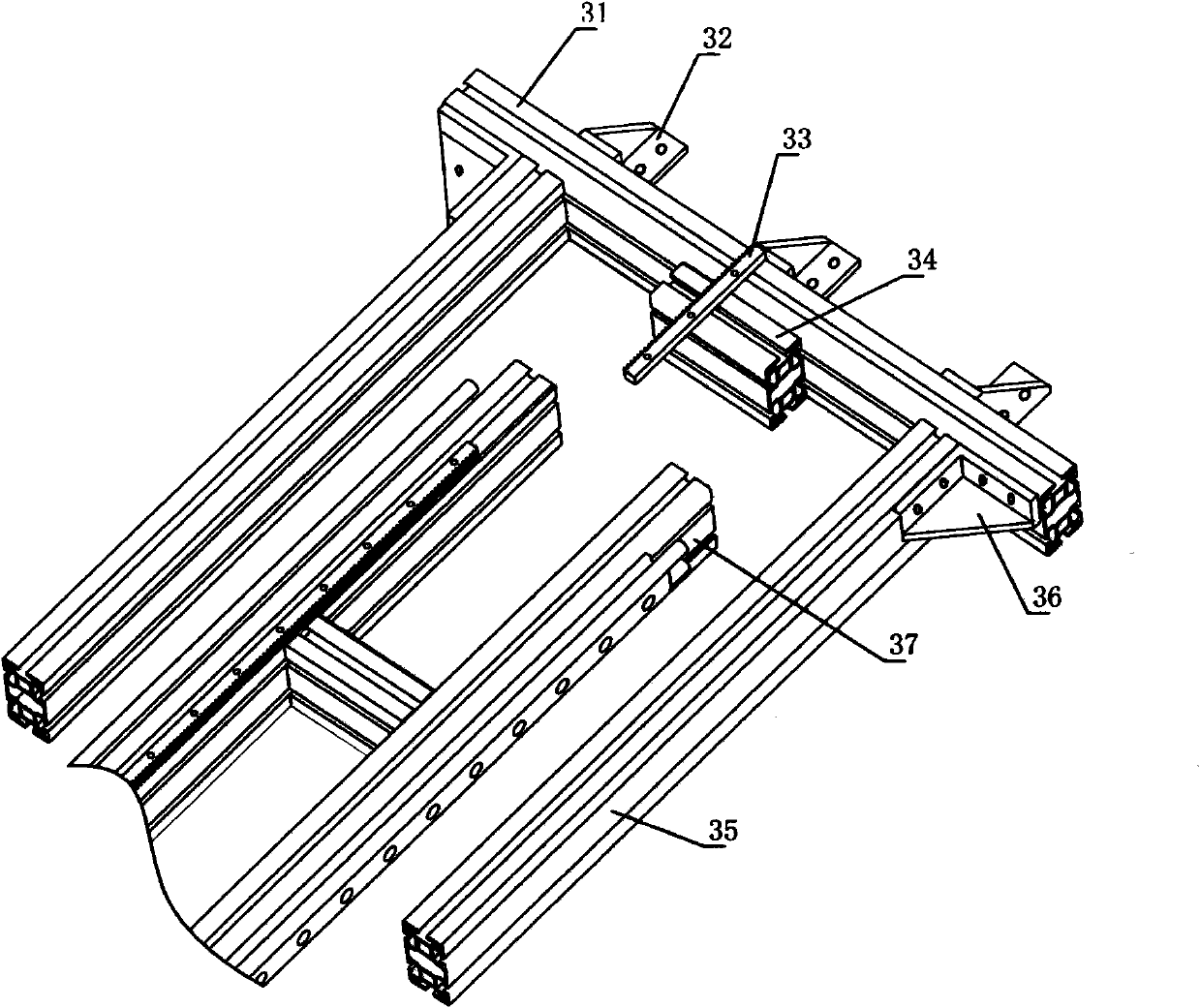

[0019] The central idea of the present invention: by improving the docking surface of the portable splicing guide rails, using interlaced positioning pins, positioning holes, and connecting pin shafts for accurate positioning, a simple, fast and reliable guide rail docking operation for non-professionals is realized The process expands the scope of application of product processing dimensions, improves performance, simplifies disassembly and assembly, and reduces the labor intensity of after-sales personnel.

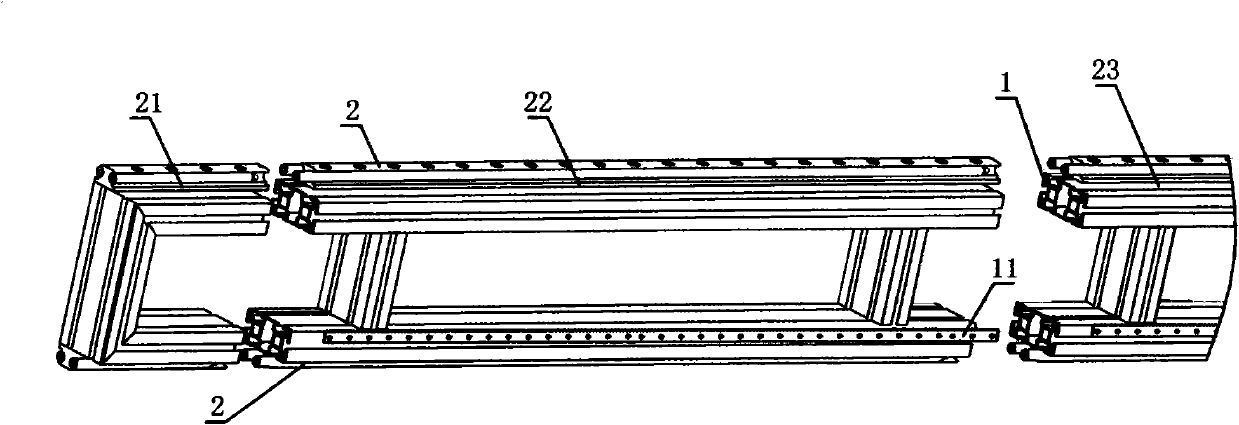

[0020] Taking the H-shaped splicing guide rail used on the portable numerical control cutting machine as an example, the present invention will be further described in conjunction with the accompanying drawings:

[0021] Such as figure 1 As shown, a portable splicing guide rail, the overall shape of the splicing guide rail is H-shaped, including a set of guide rail bodies 2 and aluminum-plastic beams 1 respectively arranged along the vertical direction on both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com