Method for lifting and carrying overweight hull section by utilizing combination tool of hinge and heeling-preventing support

A technology of segmented hoisting and combination tools, applied in transportation and packaging, ship parts, ship construction, etc., can solve problems such as fierce competition and the impact of shipyards' ability to accept orders, and achieve easy production, assembly and connection, excellent loading effect, and safety. The effect of sexual assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

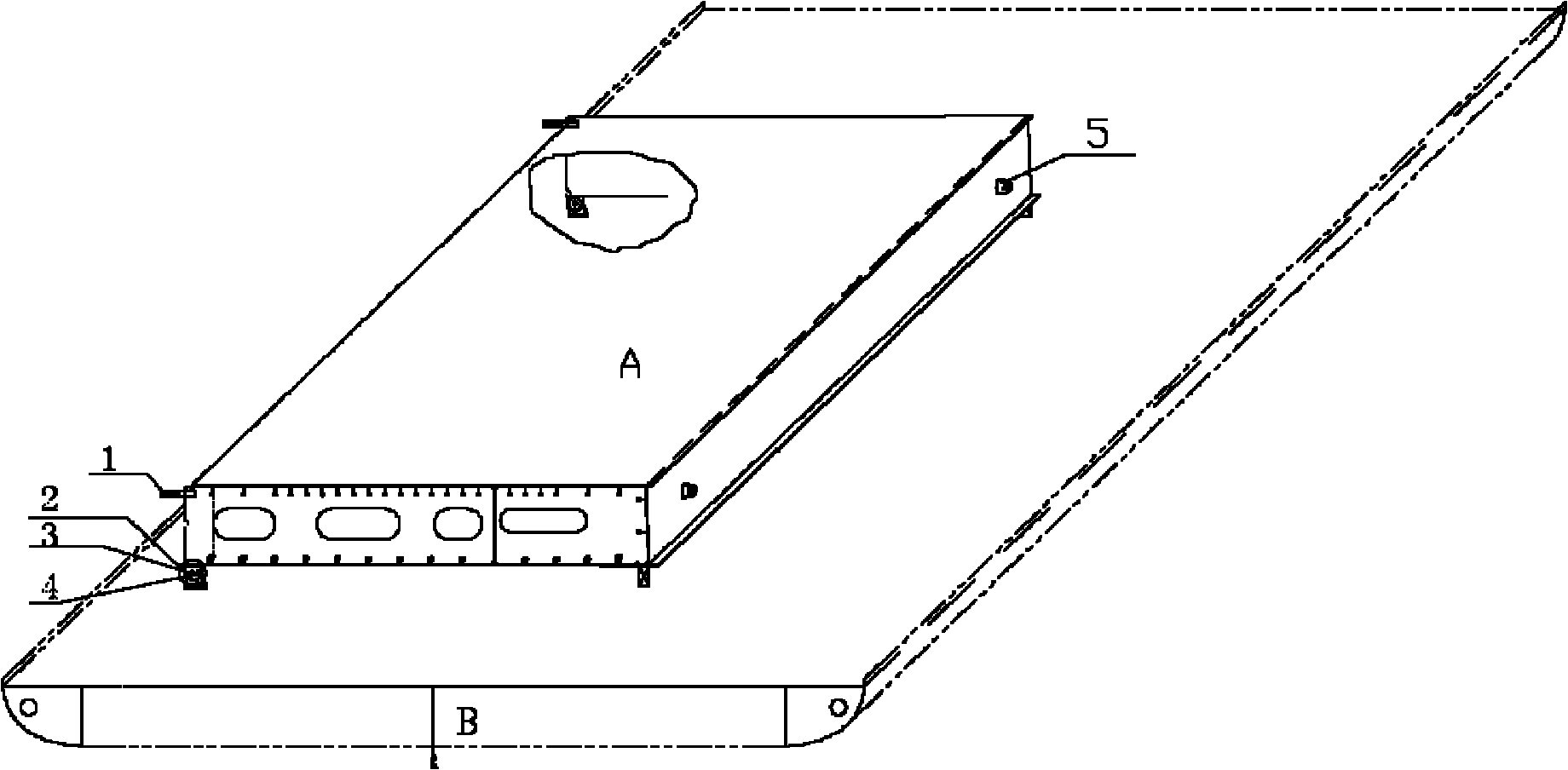

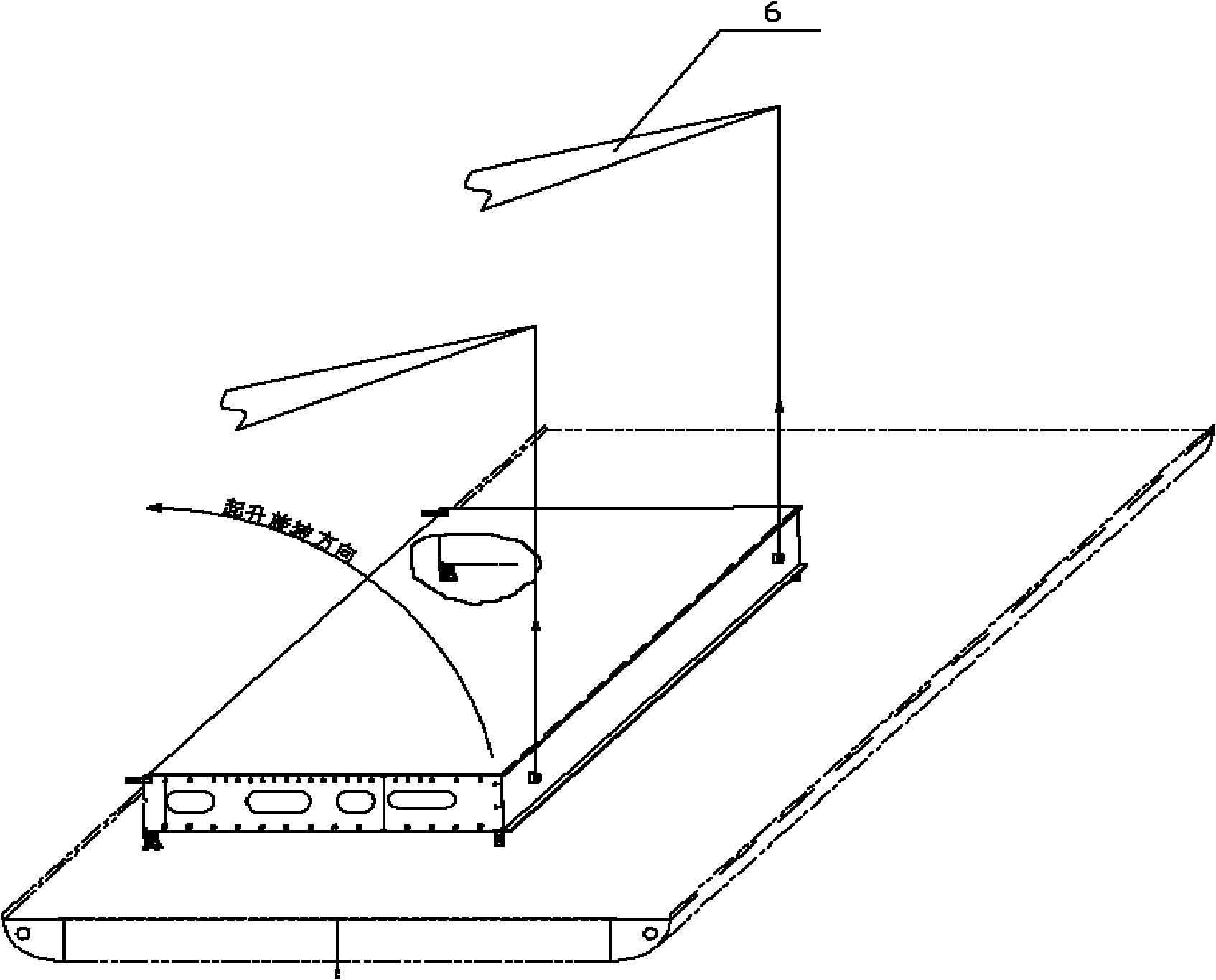

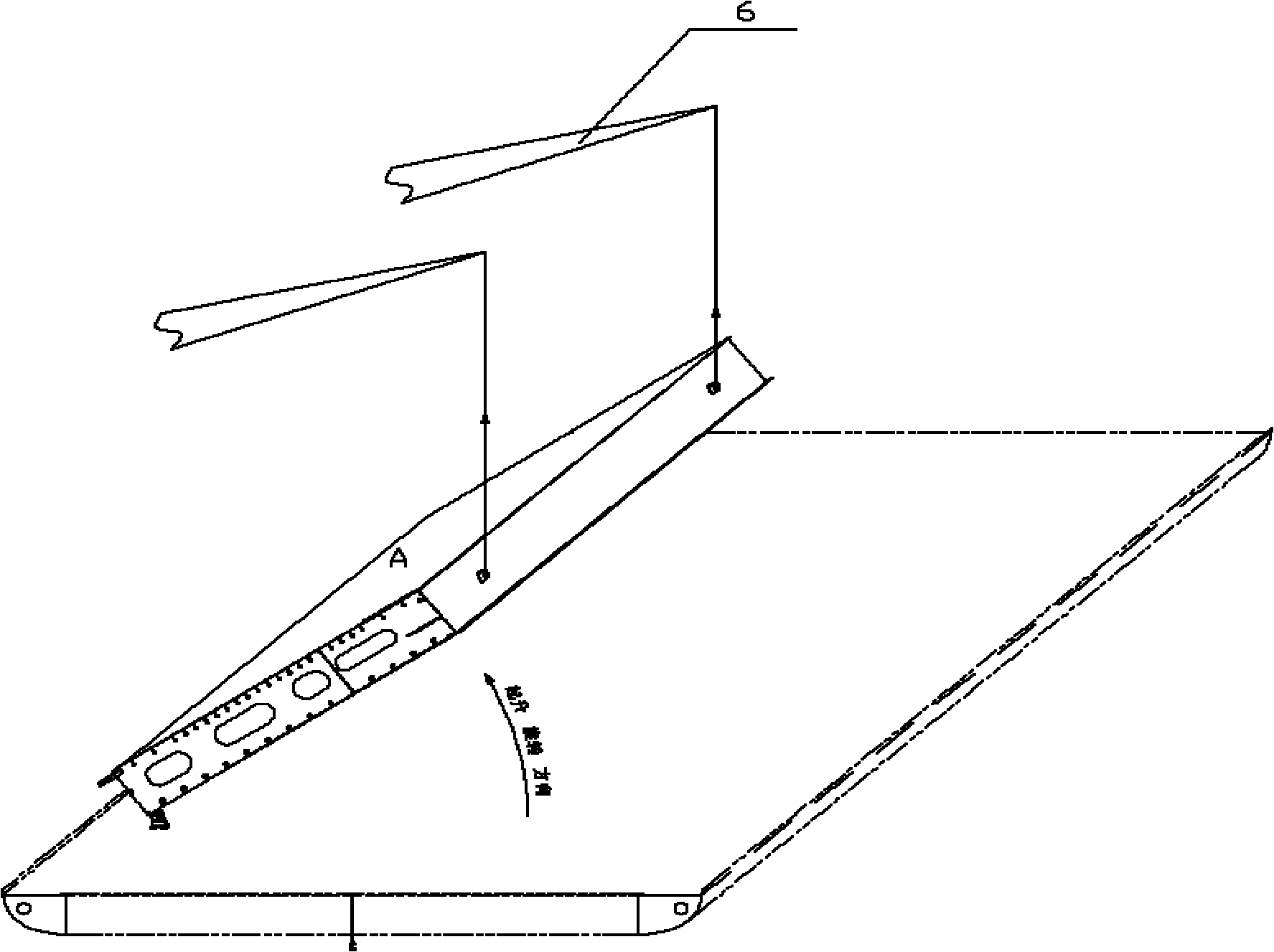

[0017] In conjunction with the accompanying drawings, the method for segmental hoisting of a super-heavy hull by using a combination tool of a hinge and an anti-heeling bracket of the present invention is described.

[0018] Such as Figure 2 to Figure 5 As shown, the present invention utilizes the combined tool of hinge and anti-heel bracket to carry out the method for carrying out the subsection hoisting of super-heavy hull, and the method includes the following steps:

[0019] ①Preparation before hoisting and hoisting of the hull in sections

[0020] Install hinge and anti-heeling bracket 1, hinge includes hinge seat plate 2, hinge 4, bearing pin 3, hinge seat plate 2 is assembled and welded on the inner floor of hull section B that has been carried, and hinge 4 is assembled and welded in waiting On the hull segment A to be carried, the hinge seat plate 2 is connected with the hinge 4 with a pin 3, and two lifting lugs 5 are assembled and welded on both sides of the main d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com