Coating machine

A technology of coating machine and coating knife, which is applied in the direction of coating, device for coating liquid on the surface, textile and paper making, etc. It can solve the control influence of thickness and coating amount, and cannot completely ensure that the rotating arm does not move, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

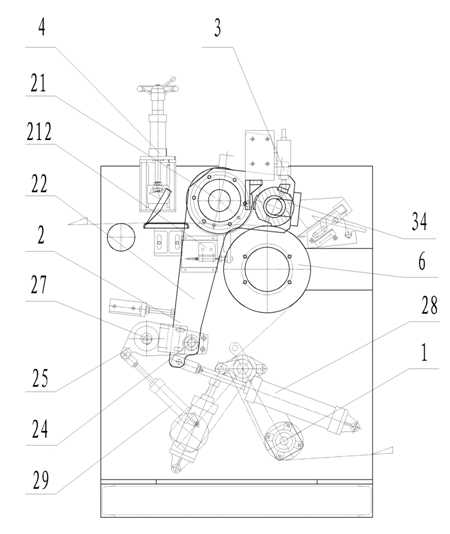

[0023] Such as figure 1 As shown, the coating machine of the present invention includes a frame 5 on which a tension tracking mechanism 1 , a rotating arm mechanism 2 , a front coating knife mechanism 3 and a rear coating knife mechanism 4 are arranged in sequence.

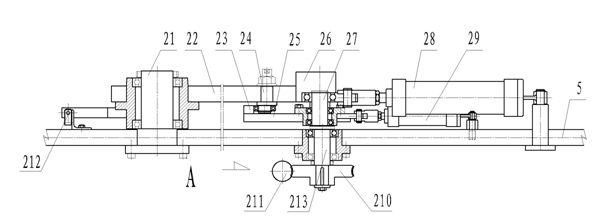

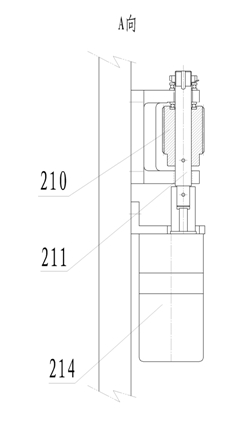

[0024] The rotary arm mechanism 2 of the coating machine of the present invention is as figure 2 , image 3 Shown, comprise the main rotating arm 22 that is arranged on the frame 5 and be used to drive the main cylinder 28 of main rotating arm 22, one end of main rotating arm 22 is hinged with the piston rod of main cylinder 28, and the other end is connected with the front coating The knife mechanism 3 is connected. The rotating arm mechanism 2 also includes a locking mechanism for fixing the main rotating arm 22. The main rotating arm 22 is provided with a locking shaft 24 that is matched with a locking mechanism near its hinged end. The locking shaft 24 includes a locking shaft fixed on the main rotating arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com