Tunnel excavation construction method

A tunnel excavation and construction method technology, which is applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of variable cross-section construction difficulty, heavy construction workload, and severe cross-section changes, so as to avoid the risk of excavation expansion, The effect of small construction workload and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The idea, specific steps and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

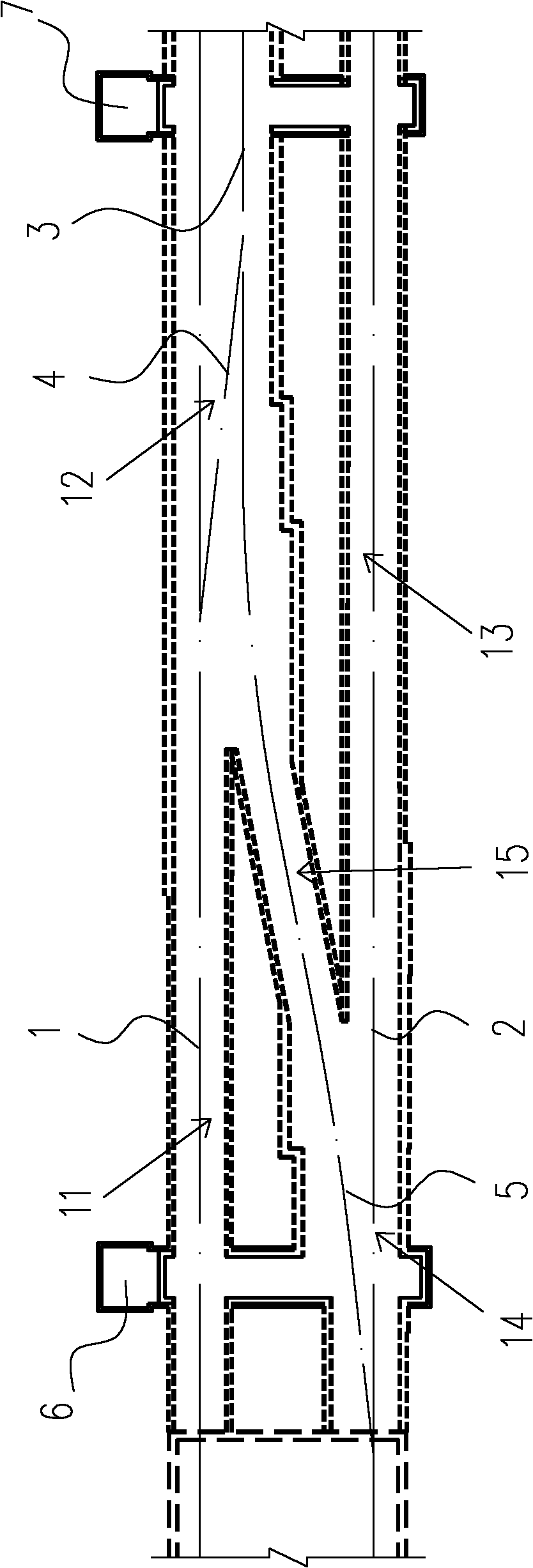

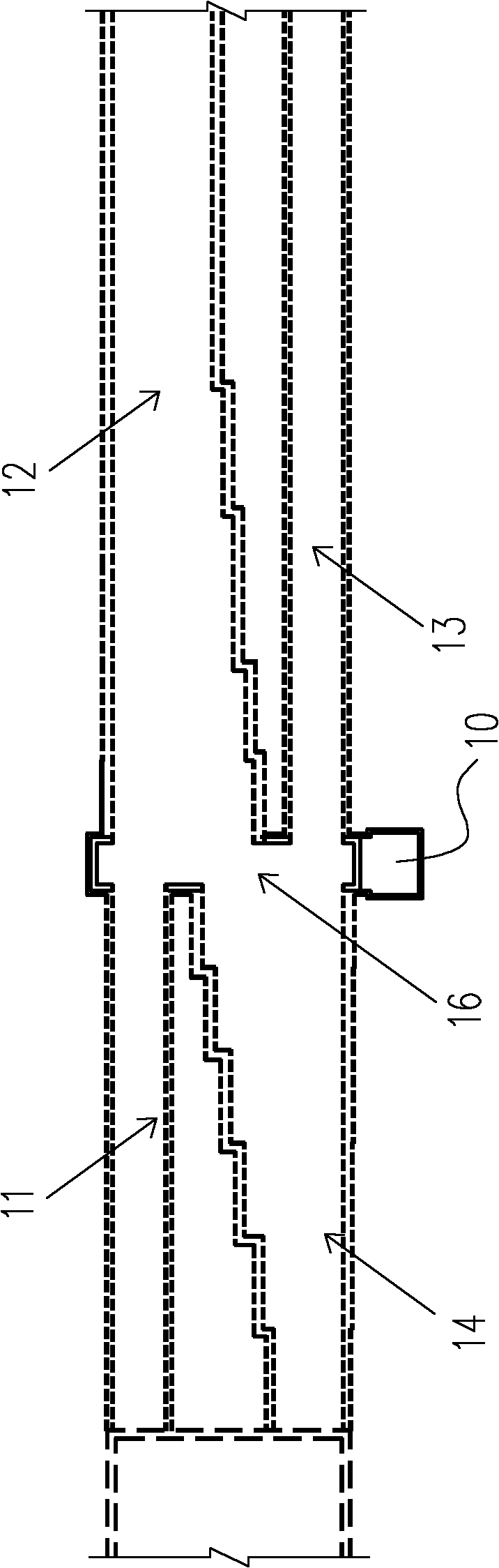

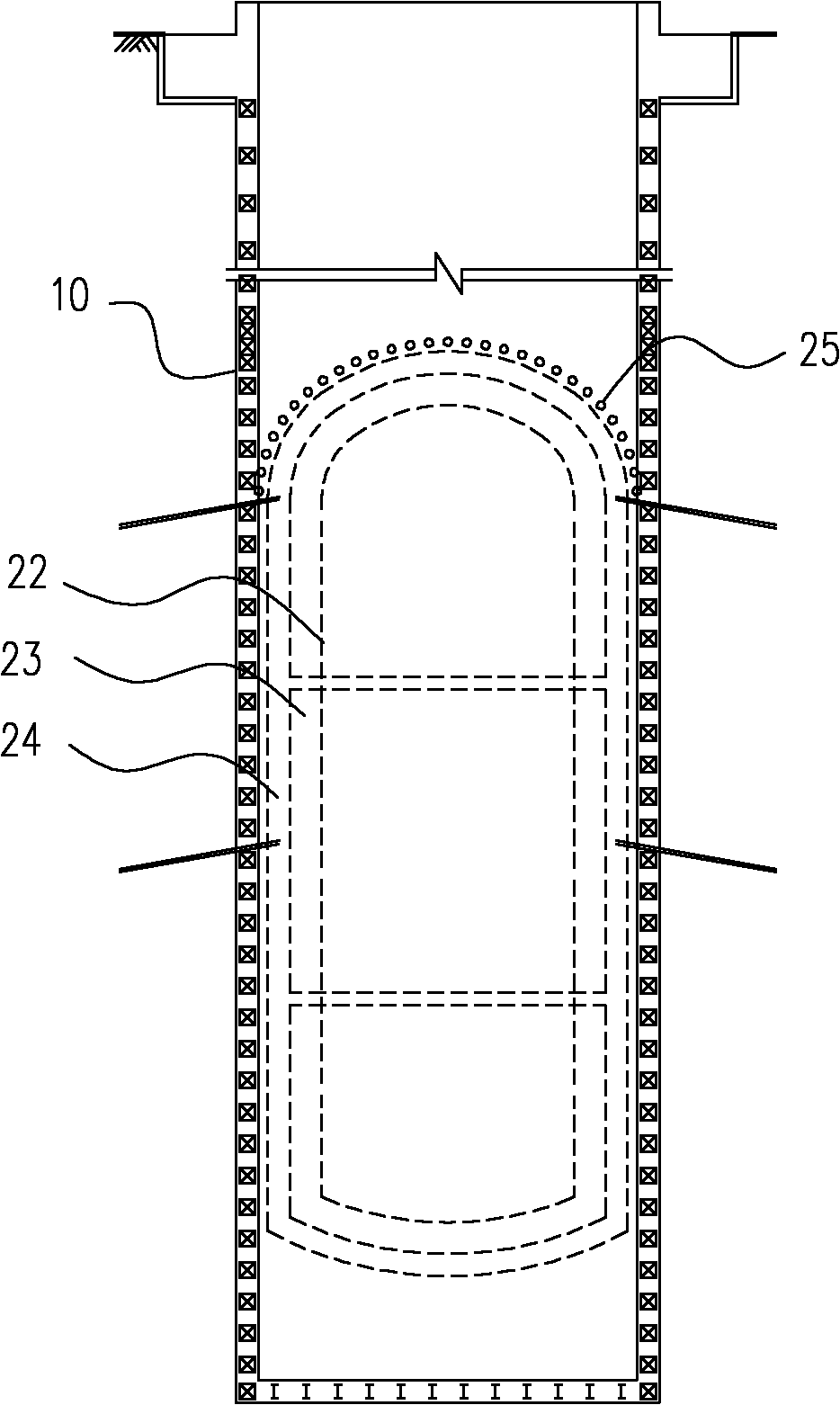

[0039] Such as figure 2As shown, in the subway tunnel excavation construction method provided by the present invention, the tunnel to be excavated includes the conventional section 11 of the first main line tunnel, the enlarged section 12 of the first main line tunnel, the conventional section 13 of the second main line tunnel, The second mainline tunnel expansion section 14 and the tunnel section 16 with the largest cross-section. Because the method provided by the present invention is mainly used for the excavation construction of subway interval tunnels containing crossing lines and stop lines, the conventional section of the first main line tunnel mentioned here refers to the tunnel section that only accommodates the first main li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com