Fast wiring interlocking electrical connector

A technology of electric connector and lock type, which is applied in the direction of connection, fixed connection, and installation of connecting parts, etc. It can solve the problems of connectors not having interlocking function, large size of connectors, and inconvenient maintenance, etc., and achieves the goal of connecting Good reliability, convenient and fast use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

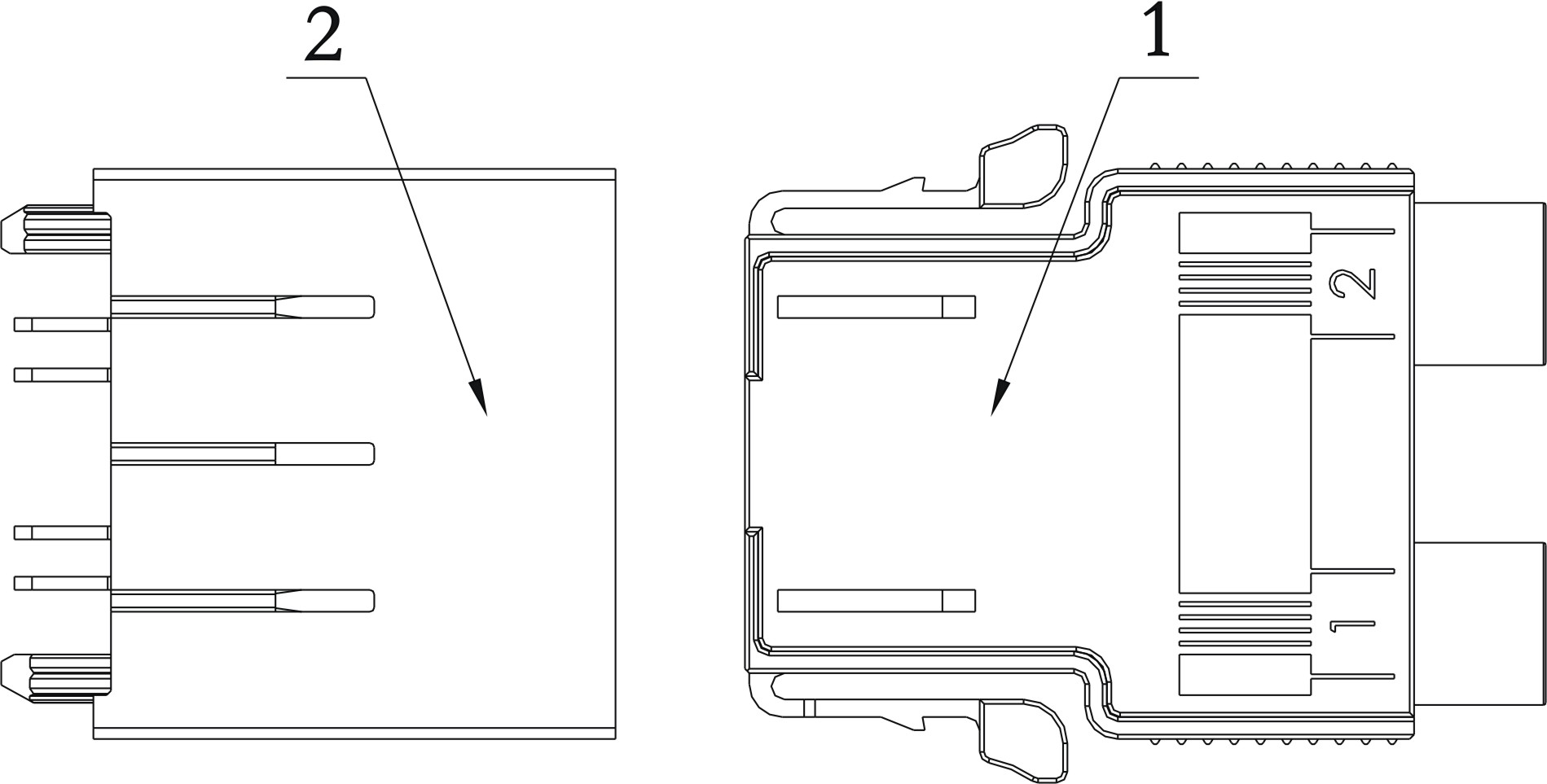

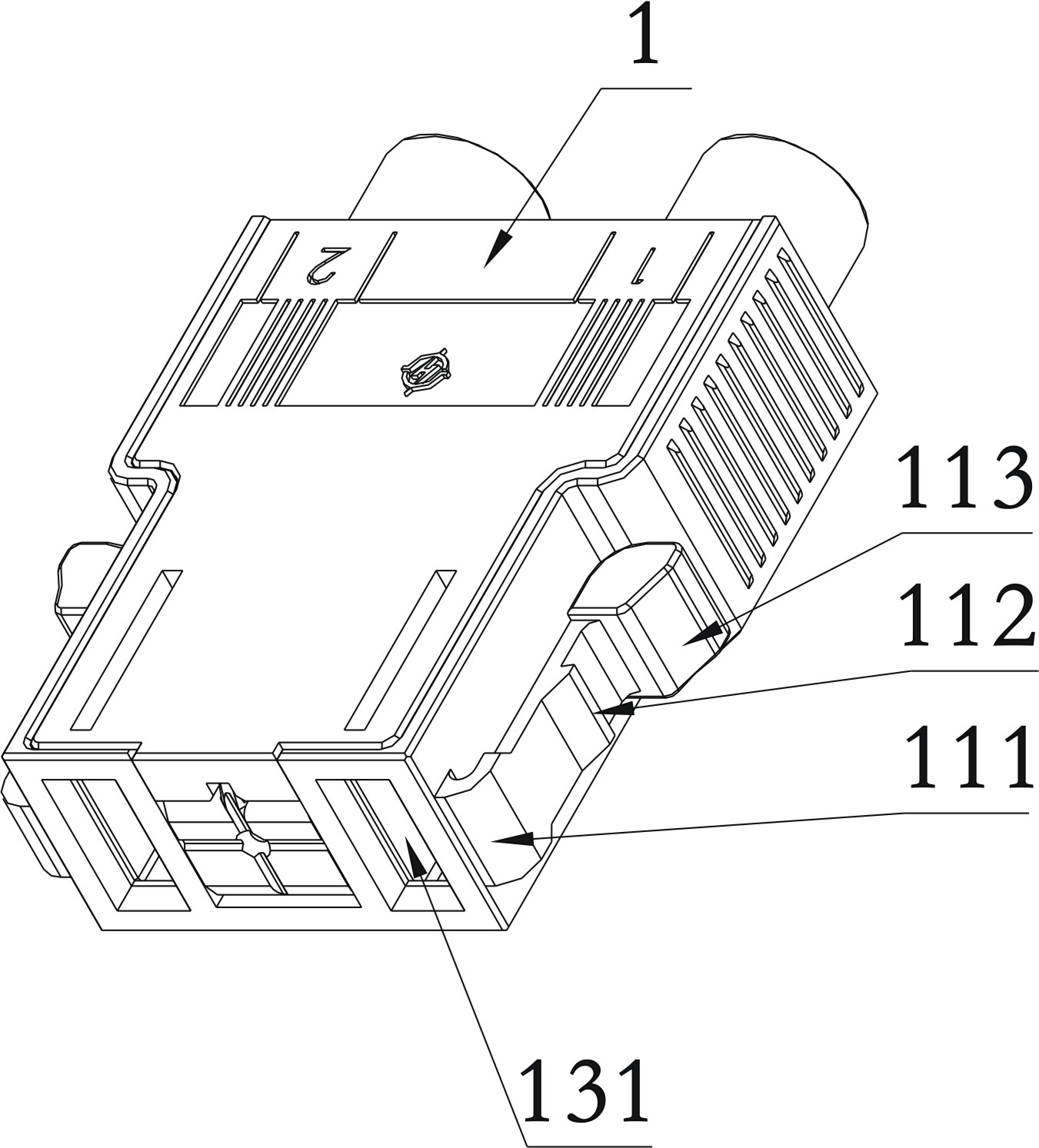

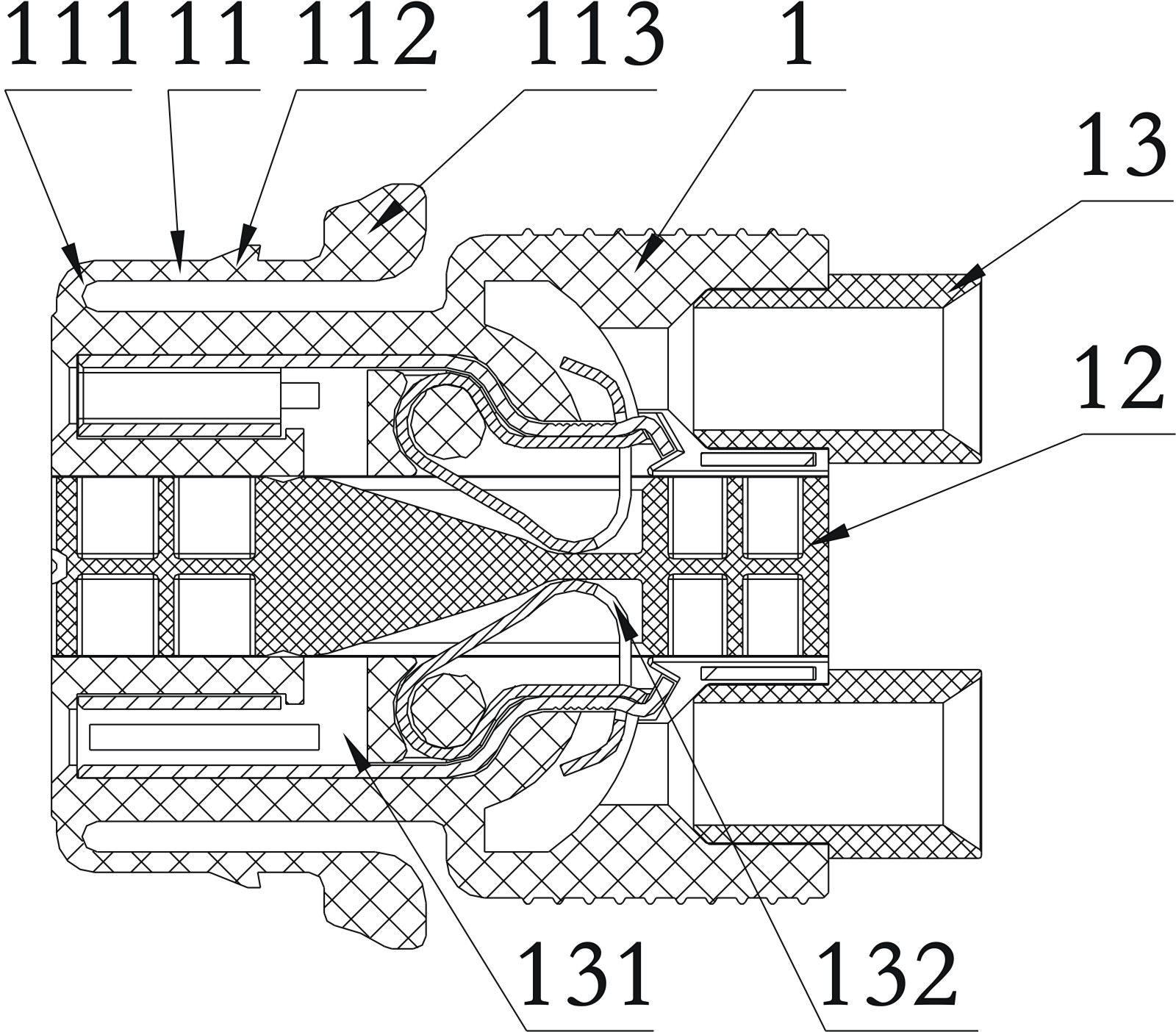

[0035] Such as figure 1 As shown, the quick wiring interlocking electrical connector includes a plug 1 and a socket 2, and is characterized in that: the plug 1 includes a base, a clamping spring 132 and a slider 12 arranged in the base, and a The elastic buckle 11 outside the seat; one end of the base is provided with a jack 131 for plugging in with the pin, and the other end of the base is provided with a wiring jack; the clamping spring 132 is set in the jack 131 and the wiring jack; the inner wall of the jack 131 is provided with a metal sheet for connecting pins and wiring; the elastic buckle 11 is composed of a buckle connecting arm 111, a buckle hanging table 112 and a buckle button 113; the buckle connecting arm 111 is kept parallel to the outer surface of the base, one end of the buckle connecting arm 111 is smoothly an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com