High-power permanent magnet synchronous generator

A permanent magnet synchronous and generator technology, applied in synchronous machines, synchronous machine parts, electrical components, etc., can solve the problems of increasing the volume of the generator, increasing the amount of permanent magnets, and increasing the cost of the generator, so as to ensure the magnetic energy product. , the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

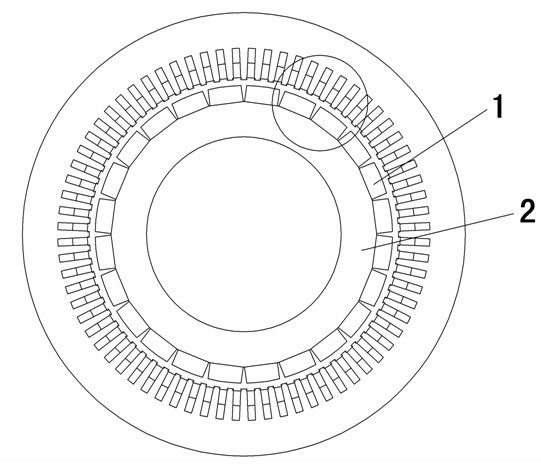

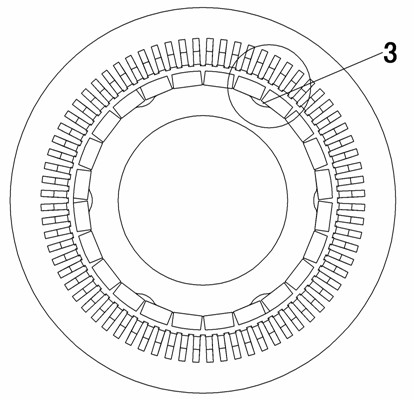

[0054] see Figure 8 , the second embodiment of the present invention. In this embodiment, under abnormal operating conditions such as generator overload operation and sudden short circuit, the two permanent magnets passing through or closest to the center of each pole of the rotor are at the maximum demagnetization field strength of each pole. The magnet 1 gap is described. The auxiliary mechanism in this embodiment is the permanent magnet 7 arranged in the rotor core at the above-mentioned gap position, and the permanent magnet 7 penetrates the entire rotor core 2 along the rotor axial direction.

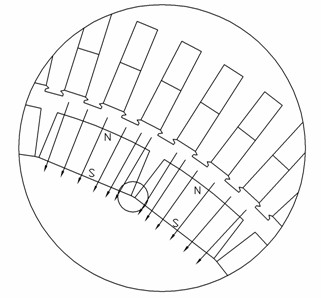

[0055] see Figure 9 , taking one pole of the rotor as an illustration. The side of the permanent magnet 1 of the rotor pole away from the rotor axis is the N pole, and the side close to the rotor core 2 is the S pole. Abnormal operations such as overload operation and sudden short circuit of the generator The direction of the demagnetizing magnetic field generated in the state ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com